Externally-used sand pulp coating adopting glutinous rice emulsion

A technology of emulsion and mortar, applied in the field of coatings, can solve problems such as memory loss, health damage, and non-conformity to environmental protection, and achieve the effects of improving mechanical strength, weather resistance, gloss and color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

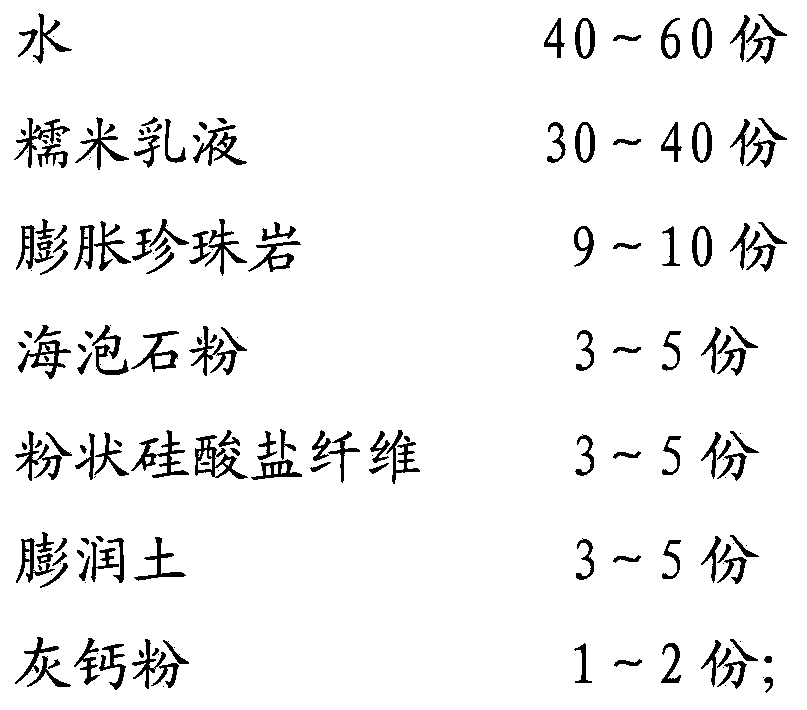

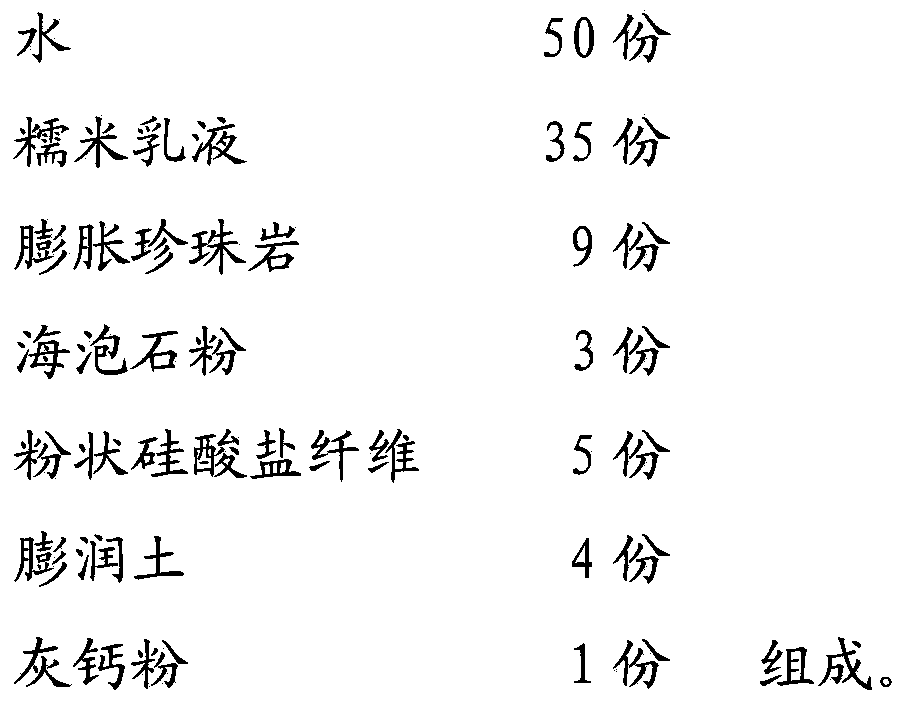

[0014] Select by mass meter

[0015]

[0016] Follow the steps below:

[0017] ①Put the water and glutinous rice slurry into the reactor according to the formula and stir for 15-30 minutes;

[0018] ②Add expanded perlite, sepiolite powder, powdered silicate fiber, bentonite, lime calcium powder in sequence at a stirring speed of 900r / min~1100r / min, and stir for 20-40min;

[0019] ③The finished product contains the external mortar paint containing the glutinous rice syrup film-forming auxiliary agent and packaged from the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com