Method for preparing electrode for fuel cell

An electrode and substrate technology, applied in the field of electrode preparation, can solve the problems that the electrode needs to be improved, and achieve a good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

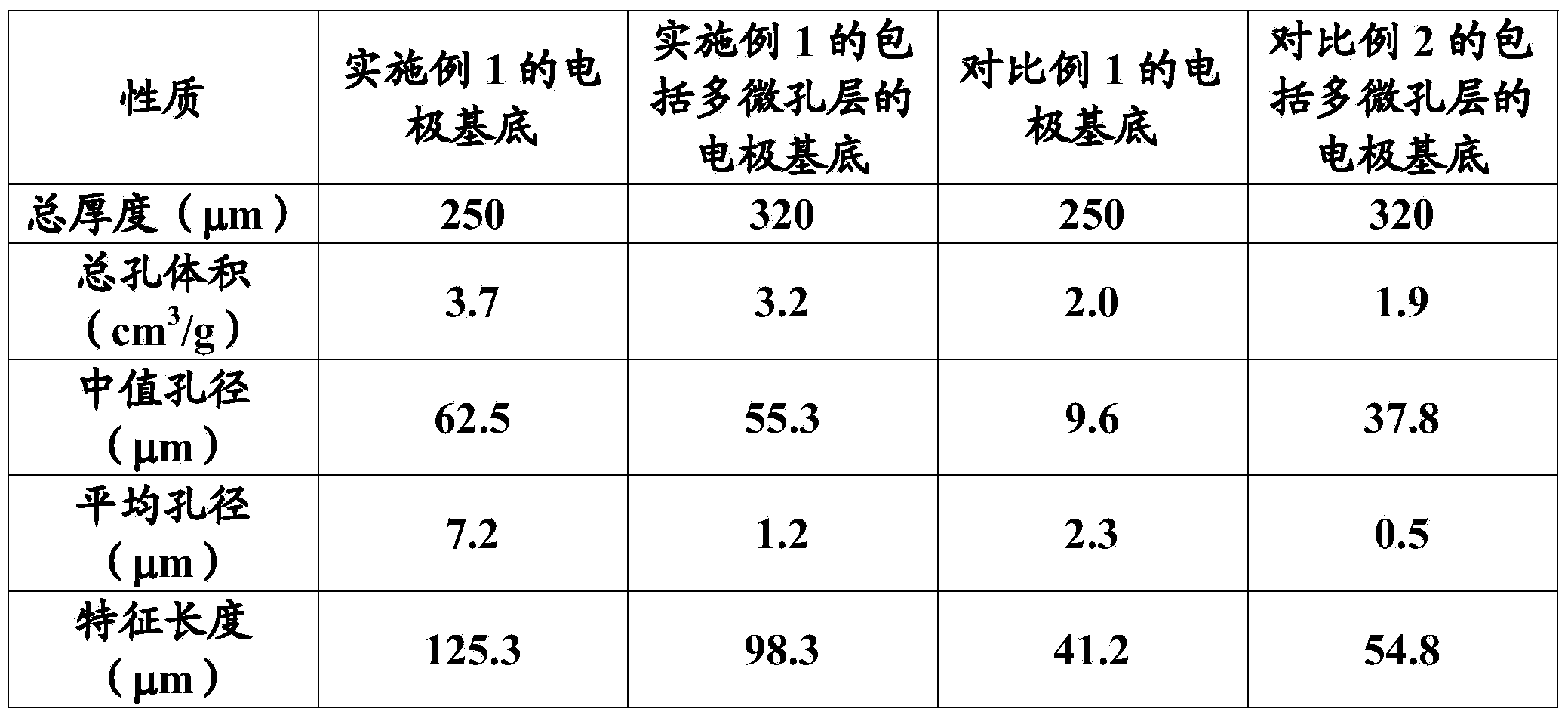

Image

Examples

Embodiment 1

[0079] The 250 μm thick carbon cloth was immersed in polytetrafluoroethylene (PTFE) emulsion four times, and the sample was dried after each immersion (using low-temperature rapid drying), and finally sintered at 340 ° C. The weight percentage of polytetrafluoroethylene is about 20%.

[0080] 2 g of carbon black, 0.2 g of carbon nanotubes, 0.8 g of polytetrafluoroethylene (PTFE) and 20 g of water as a solvent were ultrasonically mixed, and then heated (about 50° C.) to obtain a slurry. This mixture was coated on the above-mentioned PTFE-treated carbon cloth with a thickness of 250 μm, and sintered at 340° C. to form a microporous layer.

[0081] Take 20ml of 0.5mol / L Ni(NO 3 ) 2 Ethanol solution, add 1.0g of polyethylene glycol, heat to dissolve, as a catalyst solution, immerse the carbon cloth with a microporous layer obtained above in the catalyst solution for 20min, take it out, and dry it; The carbon is arranged in the middle area of the quartz tube in the horizontal ...

Embodiment 2

[0090] The 250 μm thick carbon cloth was immersed in polytetrafluoroethylene (PTFE) emulsion four times, and the sample was dried after each immersion (using low-temperature rapid drying), and finally sintered at 340 ° C. The weight percentage of polytetrafluoroethylene is about 20%.

[0091] 2g of carbon black, 0.2g of carbon nanotubes, 0.8g of polytetrafluoroethylene (PTFE) and 20g of water as a solvent were ultrasonically mixed, and then heated (about 50°C) to obtain a slurry, in which pore-forming CaCO 3 (0.01g) and mix well. This mixture was coated on the above-mentioned PTFE-treated carbon cloth with a thickness of 250 μm, and sintered at 340° C. to form a microporous layer.

[0092] Take 20ml of 0.1~1mol / L Ni(NO 3 ) 2 Ethanol solution, add 0.1-2.0g of polyethylene glycol, heat to dissolve, as a catalyst solution, immerse the carbon cloth with a microporous layer obtained above in the catalyst solution for 20min, take it out, and dry it; The carbon with the catalyst...

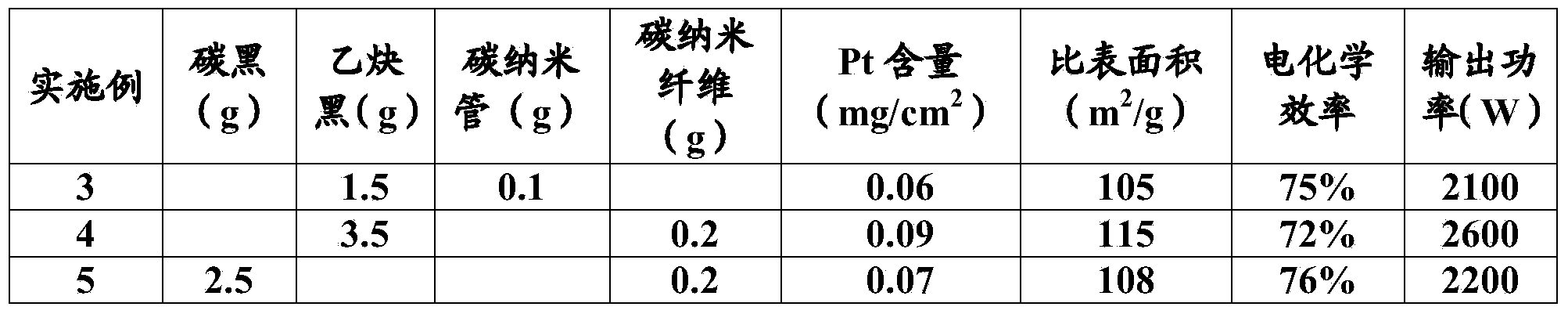

Embodiment 3-5

[0096] Basically consistent with Example 2, only the components and contents of the microporous layer were changed in Examples 3-5, and the specific data and results are listed in Table 2.

[0097] Table 2

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com