Colored photosensitive resin composition

A photosensitive resin and composition technology, applied in optics, filters, optical components, etc., can solve the problems of brightness (not necessarily sufficient brightness)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0383] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In the examples, % and parts indicating the content or the amount used are mass standards unless otherwise specified.

Synthetic example 1

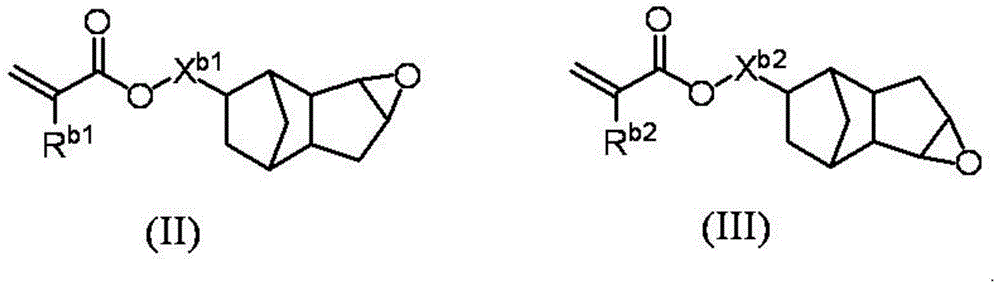

[0385] An appropriate amount of nitrogen was poured into a flask equipped with a reflux condenser, a dropping funnel, and a stirrer to form a nitrogen atmosphere, 100 parts of propylene glycol monomethyl ether acetate was added, and the mixture was heated to 85° C. while stirring. Then, 19 parts of methacrylic acid, 3,4-epoxytricyclo[5.2.1.0 2,6 ]decane-8-yl acrylate and 3,4-epoxytricyclo[5.2.1.0 2,6 ] 171 parts of a mixture of decane-9-yl acrylate (the molar ratio is 50:50) (trade name "E-DCPA", produced by Daicel Co., Ltd.) was dissolved in propylene glycol monomethyl ether acetate 40 part solution. On the other hand, 26 parts of the polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) dissolved in propylene glycol monomethyl ether ethyl alcohol was dripped into the flask over about 5 hours using another drip pump. A solution formed from 120 parts of acid ester. After the dropwise addition of the polymerization initiator was completed, it was kept at the same t...

Embodiment 1

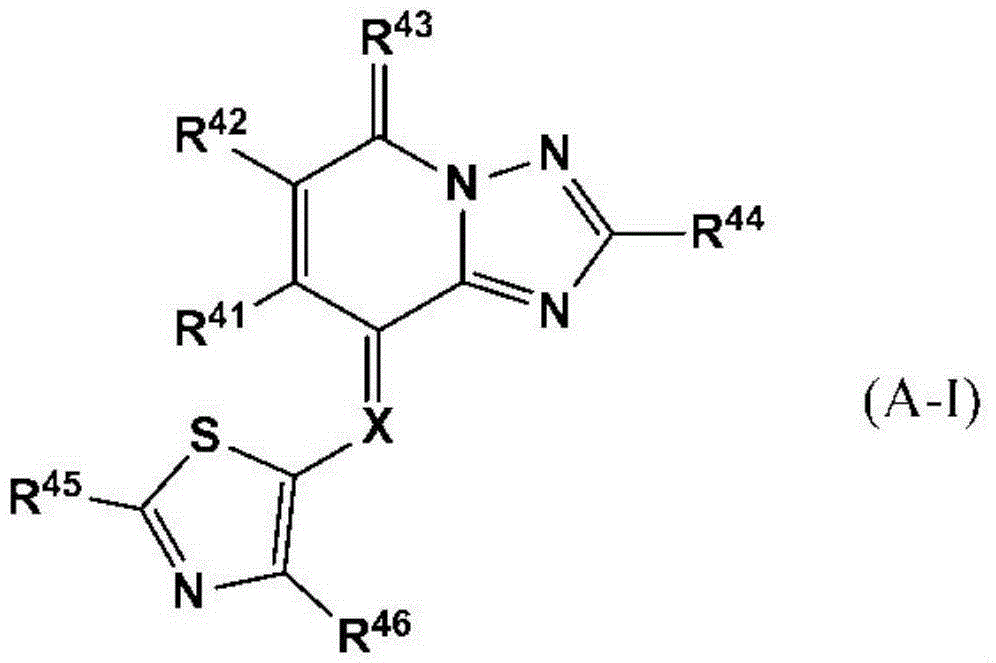

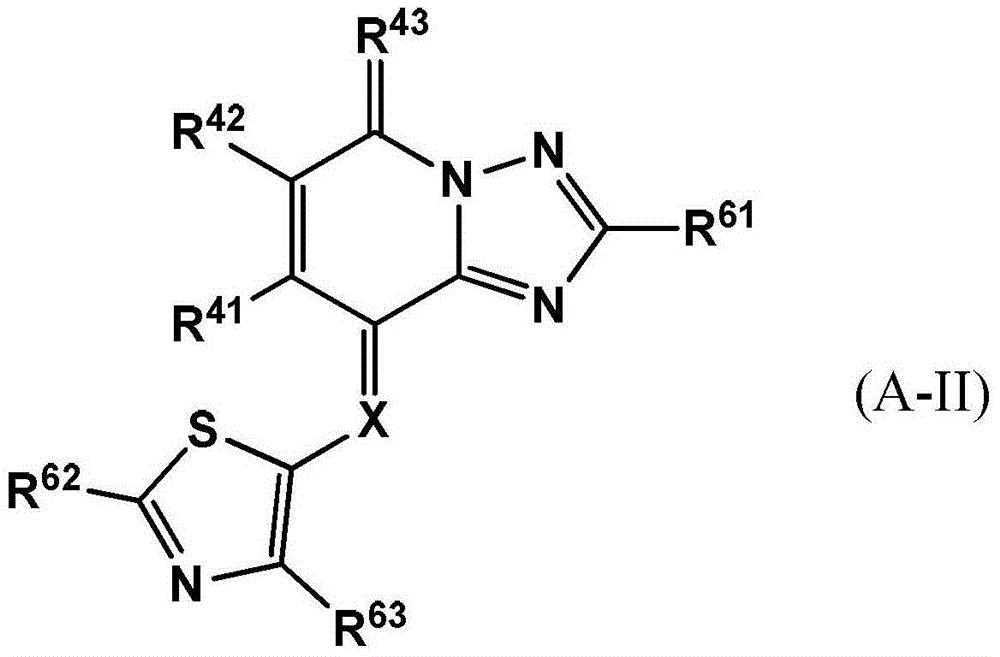

[0402]Coloring agent (A): 26 parts of thiazole dye represented by formula (A-I-1);

[0403] Alkali-soluble resin (B): 53 parts of resin (B-1) (solid content conversion);

[0404] Polymerizable compound (C): 16 parts of dipentaerythritol hexaacrylate (KAYARAD (registered trademark) DPHA; manufactured by Nippon Kayaku Co., Ltd.);

[0405] Polymerization initiator (D): N-benzoyloxy-1-(4-phenylthiophenyl)octan-1-one-2-imine (irgacure (registered trademark) OXE-01; manufactured by BASF Corporation ; O-acyl oxime compound) 4 parts;

[0406] Solvent (E): 120 parts of propylene glycol monomethyl ether acetate;

[0407] Solvent (E): 480 parts of 4-hydroxy-4-methyl-2-pentanone;

[0408] as well as

[0409] Leveling agent (F): polyether modified silicone oil

[0410] (Toray silicone SH8400; manufactured by Toray Dow Corning Co., Ltd.) 0.15 parts

[0411] Mix to obtain a colored photosensitive resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com