Composite condensing device for vehicle-mounted biomass pyrolysis equipment

A biomass pyrolysis and condensation device technology, which is applied in the field of energy and chemical industry, can solve the problems of large equipment volume, achieve the effects of reducing floor space, avoiding secondary decomposition, and reducing overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

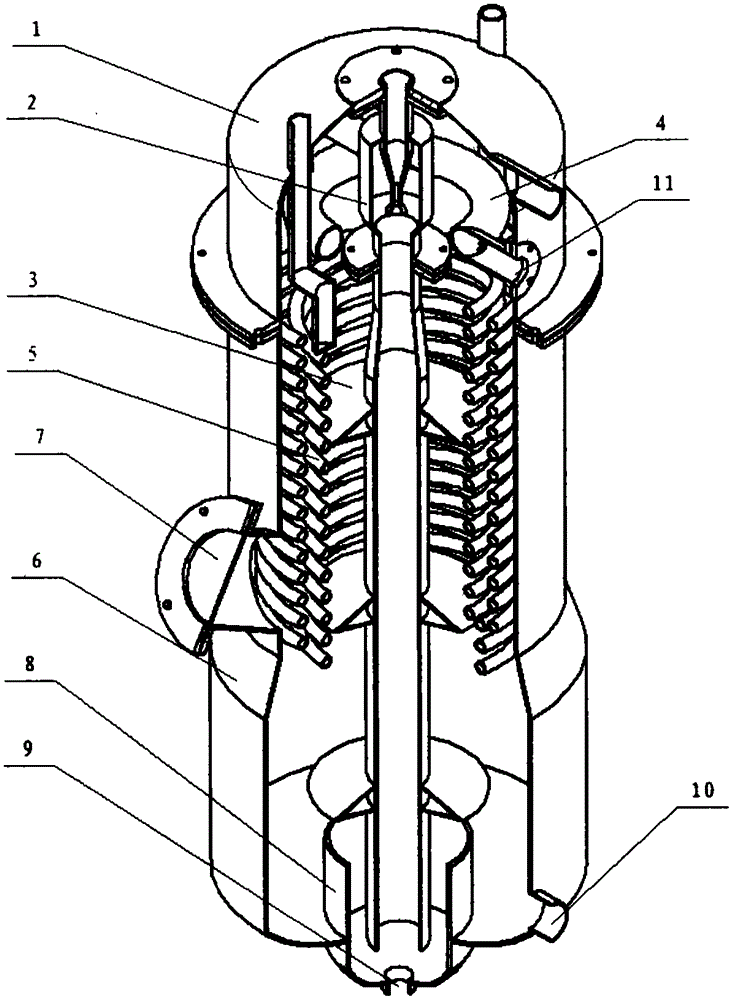

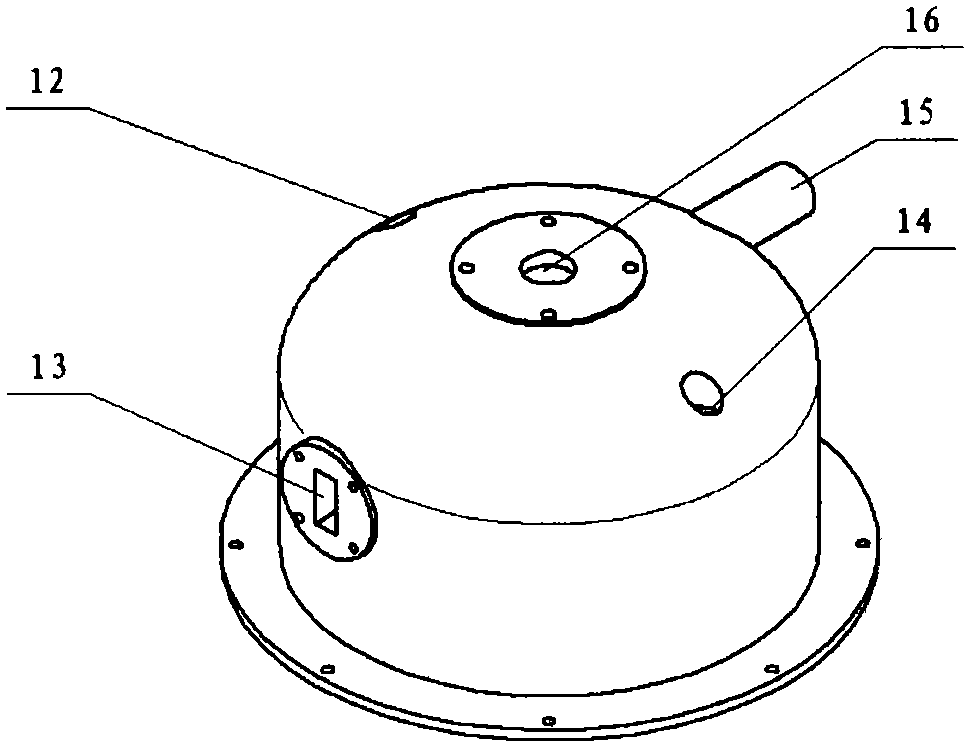

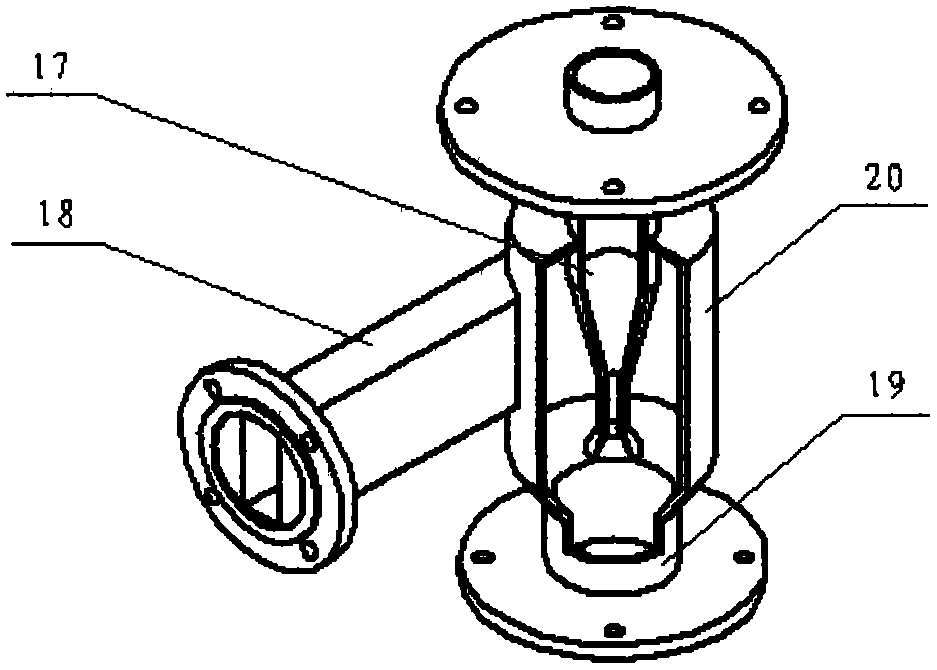

[0021] Embodiment 1: referring to accompanying drawing, a kind of composite condensing device of pyrolysis gas of biomass is characterized in that: it comprises: shell 6, top cover 1, gas-liquid mixer 2, guide pipe 3, cooling pipe 5, sprinkler 4;

[0022] The shell 6 has a cylindrical structure, with a primary condensate isolation area 8 at the bottom, a sewage outlet 9, and a liquid outlet 10 on one side. The condensed primary and secondary liquid products are stored in the primary condensate respectively. The liquid isolation area 8 and its peripheral space, the impurities therein are discharged from the sewage outlet 9 after precipitation; the liquid outlet 10 is connected with the oil pump 26, and the liquid mixture is delivered to the gas-liquid mixer 2 and the gas-liquid mixer 2 by the oil pump 26. The shower 4 is recycled;

[0023] The top cover 1 is connected above the shell 6 by a flange, and together with the shell 6 wraps the remaining components inside; the nozzle...

Embodiment 2

[0028] Embodiment 2: In the composite condensing device of biomass pyrolysis gas described in Embodiment 1, a sight glass 7 is installed in the middle of the shell 6, which is convenient for observing the internal conditions and as a hand hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com