Asphalt anti-ageing agent as well as preparation method and application thereof

An anti-aging agent and asphalt technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of asphalt's easy aging performance, and achieve the effects of improving performance indicators, improving anti-aging ability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

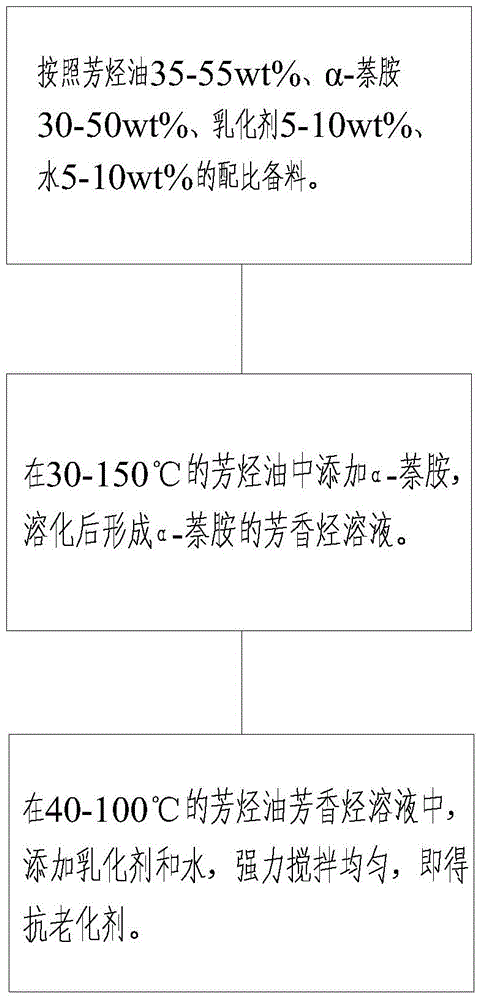

[0028] See attached figure 1 , a preparation method of asphalt anti-aging agent, comprising the following steps:

[0029] 1) Take aromatic hydrocarbon oil, add α-naphthylamine at 30-150°C, stir well, and form an aromatic hydrocarbon solution of α-naphthylamine after melting;

[0030] 2) Add emulsifier and water respectively to the aromatic hydrocarbon solution obtained in step 1) at 40-100°C, and stir vigorously to obtain the anti-aging agent.

[0031]In step 2), the temperature of the aromatic hydrocarbon solution is 50-90° C., the speed of vigorous stirring is 50-120 r / min, and the stirring time is 10-100 min.

[0032] In step 2), the temperature of the aromatic hydrocarbon solution is 70-80° C., the rotation speed of the vigorous stirring is 60-100 r / min, and the stirring time is 20-60 min.

[0033] In the step 1), the temperature of the aromatic oil is 50-120°C, and the stirring time is 0.5-5h.

[0034] In the step 1), the temperature of the aromatic oil is 50-80°C, and...

Embodiment 1

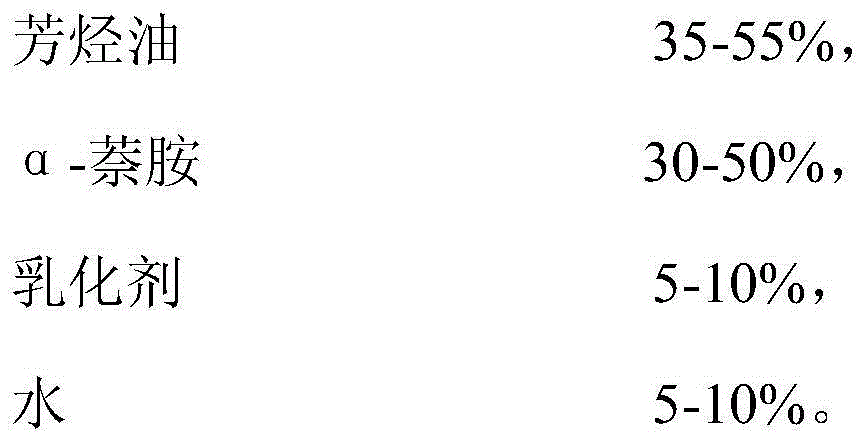

[0038] Weigh respectively the aromatic oil of 35% by weight (aromatic oil is crude oil wax oil fraction extraction oil), the pure α-naphthylamine reagent of 50% by weight, the nonylphenol polyoxyethylene ether (NP- 7) and 5% water of percentage by weight, standby;

[0039] Put the aromatic hydrocarbon oil in a reaction kettle, add the above-mentioned α-naphthylamine at 80°C, stir well, and form an aromatic hydrocarbon solution of α-naphthylamine after melting;

[0040] Add the above-mentioned nonylphenol polyoxyethylene ether and water to the above-mentioned aromatic hydrocarbon solution at 100°C, stir vigorously, and cool to obtain the anti-aging agent.

[0041] Gained antiaging agent is denoted as AR-1, and this antiaging agent is made up of aromatic oil 35wt%, α-naphthylamine 50wt%, nonylphenol polyoxyethylene ether 10wt% and water 5wt%, and it can be used for producing antiaging asphalt , improve the thermal storage period of asphalt, or produce petroleum asphalt containi...

Embodiment 2

[0043] Weigh respectively the aromatic oil of 55% by weight (the aromatic oil is furfural extract oil), the α-naphthylamine of 30% by weight, the nonylphenol polyoxyethylene ether (NP-20) of 5% by weight and the weight percent 10% of water, reserve;

[0044] Put the aromatic hydrocarbon oil in a reaction kettle, add the above-mentioned α-naphthylamine at 120°C, stir thoroughly for 4 hours, and form an aromatic hydrocarbon solution of α-naphthylamine after melting;

[0045] Add the above-mentioned nonylphenol polyoxyethylene ether and water to the above-mentioned aromatic hydrocarbon solution at 90°C, and stir at a speed of 50r / min for 60min. After stirring vigorously, cool to obtain the anti-aging agent.

[0046] Gained antiaging agent is denoted as AR-2, and this antiaging agent is made up of aromatic hydrocarbon oil 55wt%, α-naphthylamine 30wt%, nonylphenol polyoxyethylene ether 5wt% and water 10wt%, and it can be used for producing antiaging asphalt , improve the thermal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com