A special high-conductivity material for conductive powder coating and its preparation method

A conductive powder, high conductivity technology, applied in the field of conductive powder coating special high conductive material and preparation, conductive powder coating field, can solve the problems of unstable conductivity value, increased conductivity, etc., to achieve increased conductivity, stable conductivity, improved interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

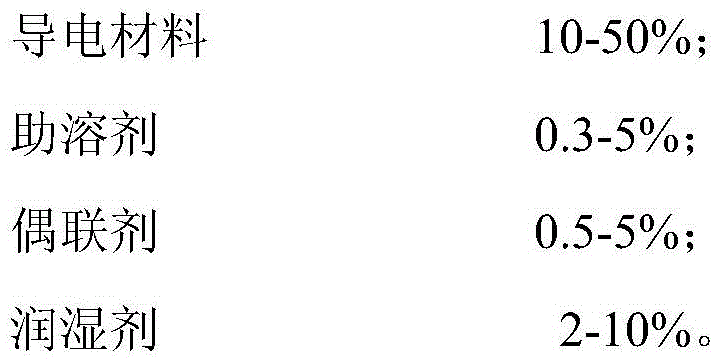

[0030] A special high-conductivity material for conductive powder coatings, its raw material constituents and weights are:

[0031]

[0032] The preparation method of the special high-conductivity material for the above-mentioned conductive powder coating, the steps are as follows:

[0033] 1. Put 60% of the above-mentioned conductive material and wetting agent into the high-speed mixer first, start the stirrer and heat at the same time and maintain a constant temperature of 80°C for 15 minutes;

[0034] 2. Mix the co-solvent, coupling agent and remaining conductive materials evenly, add them into the high-speed mixer, control the speed of the agitator (650-1450r / min) and the reaction temperature (85-105°C) in the machine, and stir at high speed for 15 minutes. Stop stirring and discharging, cool and weigh, and obtain the special high-conductivity material for conductive powder coating as A.

Embodiment 2

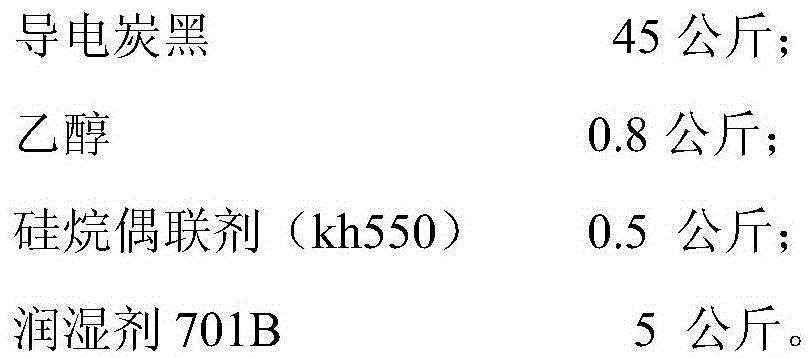

[0036] A special high-conductivity material for conductive powder coatings, its raw material constituents and weights are:

[0037]

[0038] The steps of the preparation method of the above-mentioned special high-conductivity material for conductive powder coatings are the same as in Example 1, and the obtained high-conductivity material is B.

Embodiment 3

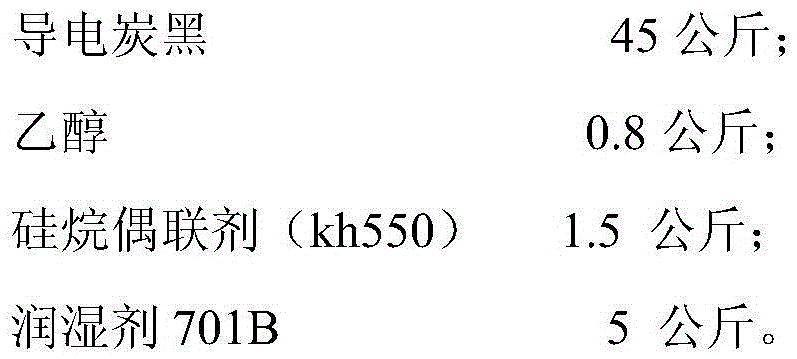

[0040] A special high-conductivity material for conductive powder coatings, its raw material constituents and weights are:

[0041]

[0042] The steps of the preparation method of the above-mentioned special high-conductivity material for conductive powder coatings are the same as in Example 1, and the high-conductivity material obtained is C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com