Lubricating and rust-proof metal cutting fluid

A metal cutting fluid, lubrication and anti-rust technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor resistance to hard water, etc., to achieve strong resistance to hard water, easy biodegradation, excellent calcium soap dispersion and resistance to hard water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

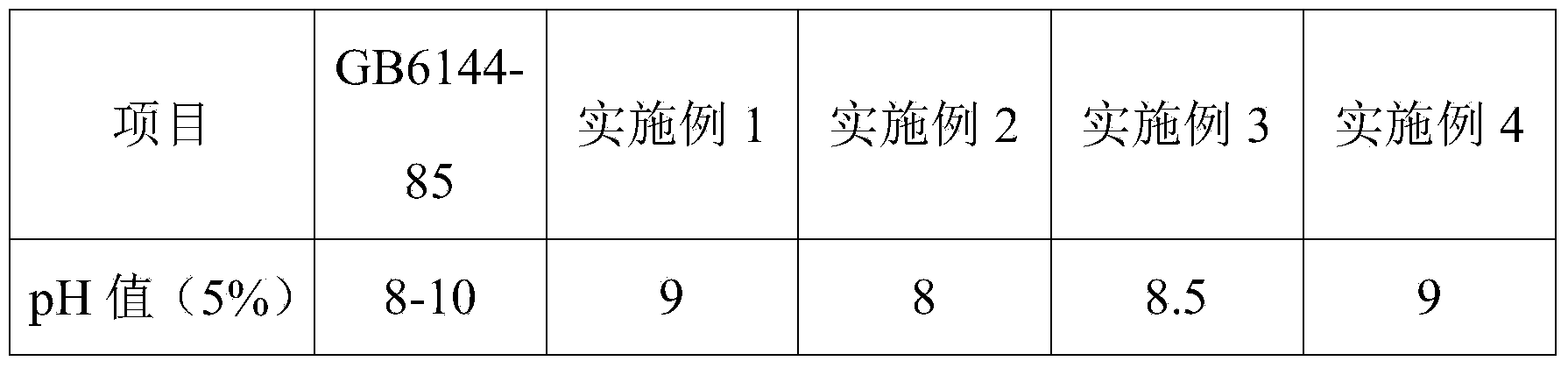

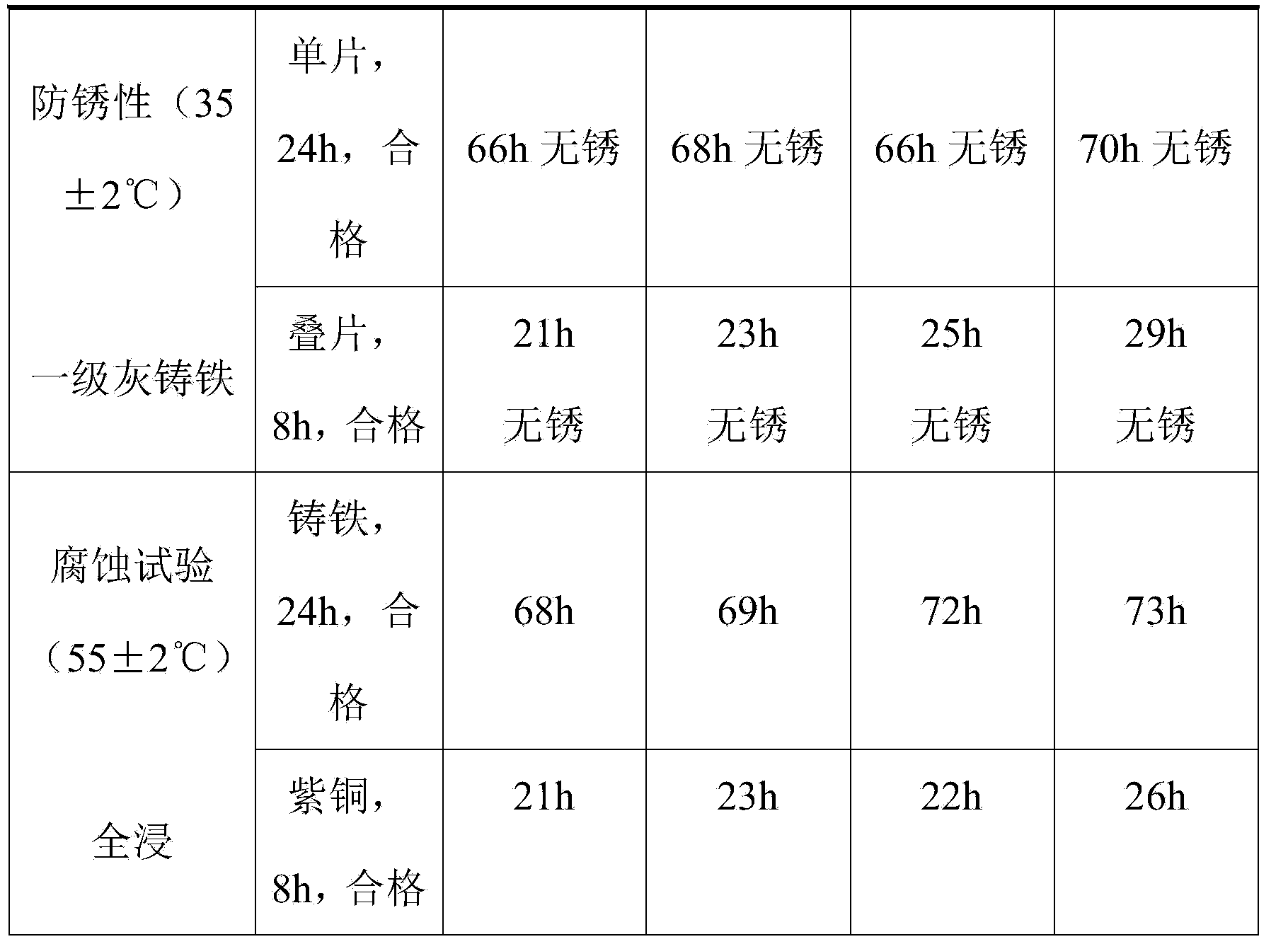

Examples

Embodiment 1

[0015] The lubricating antirust metal cutting fluid of the present invention, its raw material comprises by weight: 25 parts of sodium rosinate, 18 parts of rosin acid-N-acyl amino acid surfactant, 8 parts of quaternary ammonium salt of rosin acid, polyaniline aqueous 5 parts of preservatives, 13 parts of thiourea, 20 parts of polyethylene glycol, 10 parts of ethylenediamine, 10 parts of acetic acid, 15 parts of ethyl acetate, 10 parts of triethanolamine, 6 parts of fungicide, 5 parts of defoamer, water 30 servings.

Embodiment 2

[0017] The lubricating antirust metal cutting fluid of the present invention, its raw material comprises by weight: 40 parts of sodium abietate, 10 parts of abietic acid-N-acyl amino acid surfactant, 20 parts of quaternary ammonium salt of abietic acid, polyaniline aqueous 10 parts of antiseptic, 6 parts of thiourea, 10 parts of polyethylene glycol, 25 parts of ethylenediamine, 5 parts of acetic acid, 8 parts of ethyl acetate, 25 parts of triethanolamine, 3 parts of fungicide, 2 parts of defoamer, water 50 servings.

Embodiment 3

[0019] The lubricating antirust metal cutting fluid of the present invention, its raw material comprises by weight: 36 parts of sodium rosinate, 14.5 parts of abietic acid-N-acyl amino acid surfactant, 15 parts of rosin acid quaternary ammonium salt, polyaniline water-based anticorrosion 7 parts of agent, 12 parts of thiourea, 12 parts of polyethylene glycol, 16.8 parts of ethylenediamine, 8 parts of acetic acid, 13.5 parts of ethyl acetate, 16 parts of triethanolamine, 3.5 parts of fungicide, 3 parts of defoamer, 42 parts of water share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com