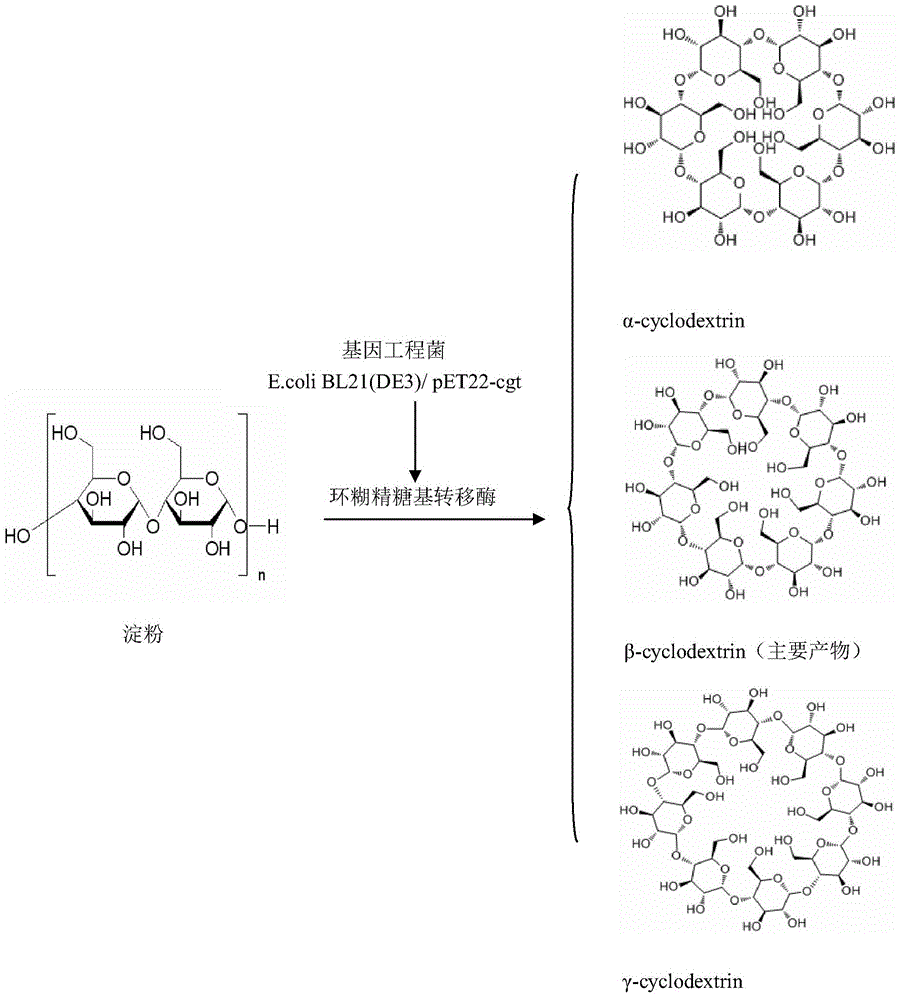

Genetically engineered bacterium for expressing beta cyclodextrin glycosyl transferase as well as construction method and use thereof

A technology of glycosyltransferase and genetically engineered bacteria, which is applied to genetically engineered bacteria expressing β-cyclodextrin glycosyltransferase and its construction field, can solve problems such as low enzyme production capacity, and achieve advanced technology, high quality, and elimination of impurities. Effects of protein and some impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Construction of recombinant expression plasmid pET22-cgt

[0027] According to the β-CGTase gene sequence that has been cloned, according to the sequence characteristics of the expression vector pET22b(+), primers were designed with the help of Primer Premier 5.0 as follows:

[0028] Forward primer: 5'CGC GGATCC GATGATTACGCCAAGCTTTA3' (BamHI);

[0029] Reverse primer: 5'ACGC GTC GAC TTACCAATTTGATATGACC3' (SalI).

[0030] Using the cloned β-CGTase gene as a template, use PCR amplification technology to obtain gene clone products containing BamHI and SalI restriction sites. The PCR product recovery procedure is as follows:

[0031] 1. Take a sterilized clean centrifuge tube and weigh it.

[0032]2. Quickly cut off the gel block containing the target fragment from the agarose gel gel plate with a clean blade under the ultraviolet light, weigh and calculate the volume of the gel block.

[0033] 3. Add 3 times the volume of the glue block melting solution B...

Embodiment 2

[0039] Embodiment 2: Construction of genetically engineered bacteria BL21(DE3) / pET22cgt

[0040] Transform the recombinant expression plasmid pET22-cgt into CaCl 2 From the treated E.coli BL21(DE3), the β-CGTase engineered strain BL21(DE3) / pET22-cgt was obtained after ampicillin resistance screening and enzyme digestion verification.

[0041] Escherichia coli competent cell preparation (CaCl 2 method) as follows:

[0042] 1. Pick a newly activated single colony from the LB plate, inoculate it in 5ml~10mL LB liquid medium, and cultivate it with shaking at 37°C for about 12 hours until the late logarithmic growth period.

[0043] 2. Inoculate the bacterial suspension in step 1 into 100 mL of LB liquid medium at a ratio of 1:100 to 1:50, and incubate with shaking at 37°C for 2-3 hours until OD600=0.4 to 0.5.

[0044] 3. Take two sterilized 50mL centrifuge tubes, add 20mL of the bacterial solution obtained in step 3 to each tube, and bathe in ice for 30min; centrifuge at 4000×g...

Embodiment 3

[0058] Embodiment 3: the expression of genetically engineered bacteria β-CGTase

[0059] Inoculate the genetically engineered bacteria E.coli BL21(DE3) / pET22-cgt into the liquid LB medium containing ampicillin 100ug / mL and culture at 37°C. When the OD600 reaches 1.0, add IPTG with a final concentration of 0.5mmol / L for induction After 6 hours, the sample was taken, and the sample was subjected to SDS-PAGE electrophoresis analysis after crushing. The molecular weight of the expressed β-CGTase protein was basically consistent with the predicted value (about 68kDa).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com