Peak power intensifier and high peak power MOPA fiber laser

A fiber laser, peak power technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems that the stability of the laser optical path system cannot be guaranteed, and the output power of the seed source is small, so as to suppress nonlinear effects and reduce The effect of optical fiber length and peak power enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

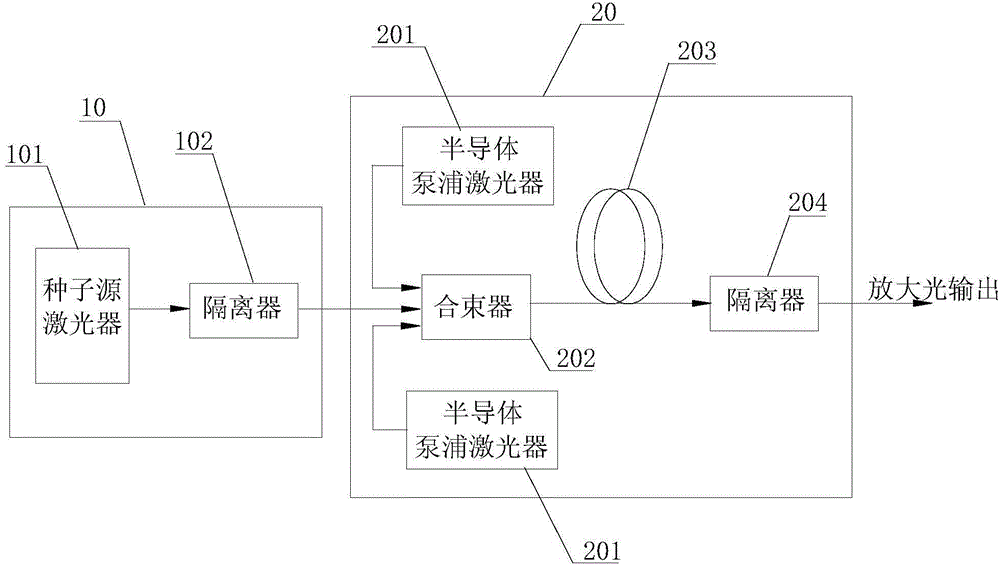

[0028] Such as Figure 5 The fiber laser shown includes a main oscillator component 1 and a power amplifier component 2 . Wherein, the main oscillator assembly 1 includes a seed source laser 11 and a forward isolator 12 , and the output end of the seed source laser 11 is connected to the input end of the forward isolator 12 by optical fiber fusion. The power amplification component 2 includes a plurality of semiconductor pump lasers 21 , a beam combiner 22 , and a peak power booster 23 . Wherein, the output ends of each semiconductor pump laser 21 and the forward isolator 12 are respectively coupled to the beam combiner 22 , and the output end of the beam combiner 22 is directly connected to the peak power booster 23 by optical fiber fusion. The structural composition of the peak power booster 23 is further introduced below:

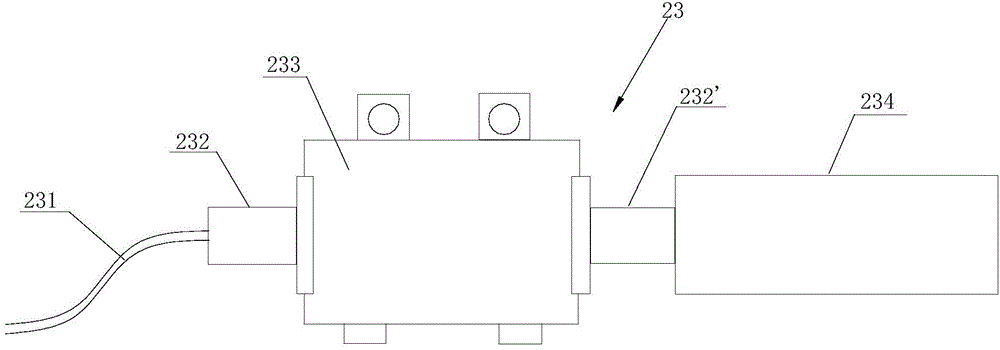

[0029] Such as image 3 The peak power booster 23 shown includes an input pigtail 231 with armor layer protection, a collimating lens, a semiconducto...

Embodiment 2

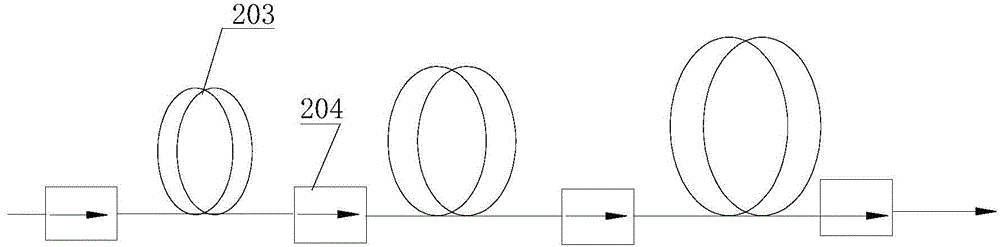

[0034] Such as Figure 6As shown, the difference between the fiber laser of this embodiment and the first embodiment is that a two-stage amplifying optical circuit 24 is also connected between the main oscillator component of the laser and the peak power booster, and the two-stage amplifying optical circuit is mainly composed of an active optical fiber and isolator. Taking the optical fiber MOPA laser in the background technology as an example, the first-stage amplification optical path is a seed pre-amplification optical path. If the output is 8ns, 100khz, 15mw, and the peak power is 18.75W, after passing through the second-stage amplification optical path, the output is 8ns, 100khz, 1W, peak power 1.25kw. The peak power intensifier of the present invention is directly fused at the output end of the second-stage amplifying optical path. Since the semiconductor pump module itself has an optical amplification effect, the magnification factor selected in this embodiment is 40 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com