Environment-friendly long-acting composite antifouling material

A long-term, environmentally friendly technology, applied in antifouling/underwater coatings, plant growth regulators, biocides, etc., which can solve the problems of narrow algae prevention species, reduced algae prevention material consumption, and short algae and antifouling lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Aiming at the aforementioned layered carrier of the present invention, an embodiment of the preparation of the loaded slow-release silver is listed below, and the preparation process and the corresponding beneficial properties are described: The general formula is AgZr 2 (PO 4 ) 3 The supported slow-release silver (wherein the weight percentage of silver ions is 3-15%; the weight percentage of zirconium phosphate is 97-85%) as an example, the preparation method includes the following steps: firstly prepare zirconium phosphate: use soluble zirconium salt (for example: sulfuric acid) zirconium oxide, basic zirconium carbonate), phosphoric acid and hydrofluoric acid are used as raw materials, and the conventional fine chemical process is adopted. vector. Then carry out silver complex ion exchange: add zirconium phosphate to the silver nitrate solution and stir for 2-4 hours, then control the pH value of the solution to be greater than or equal to 10, and further carry ou...

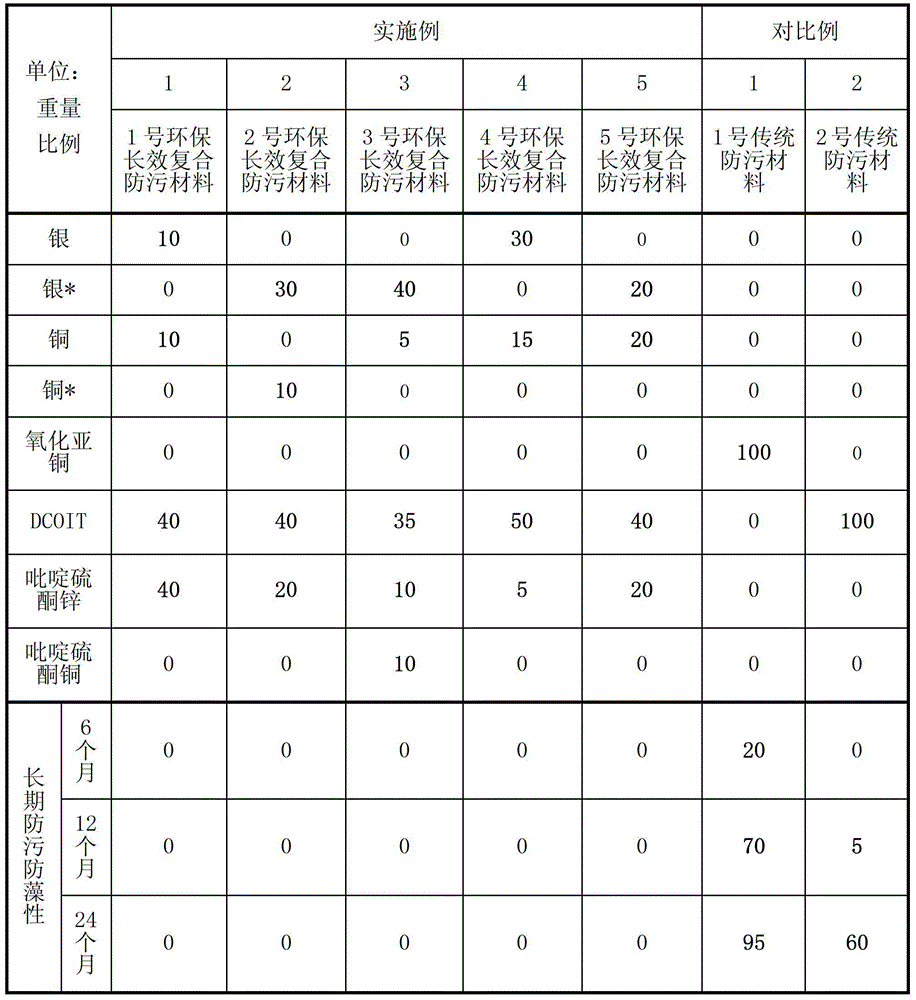

Embodiment 1

[0048] Embodiment 1: represents No. 1 environmental protection long-acting composite antifouling material, and its weight percentage is composed of:

[0049] Silver (it is loaded slow-release silver, its silver loading is 6%, its carrier is zirconium phosphate, and its particle size is 3 μm) 10%;

[0050] Copper (it is loaded slow-release copper, its copper loading is 6%, its carrier is zirconium phosphate, and its particle size is 3 μm) 10%;

[0051] Isothiazolinones (DOCIT) 40%;

[0052] Metal pyridinethione compounds (zinc pyrithione) 40%.

Embodiment 2

[0053] Embodiment 2: represents No. 2 environmental protection long-acting composite antifouling material, and its weight percentage consists of:

[0054] Silver (it is loaded slow-release silver, its silver loading is 3%, its carrier is zirconium phosphate and its structure is layered, and its particle size is 3 μm) 30%;

[0055] Copper (it is loaded slow-release copper, its copper loading is 3%, its carrier is zirconium phosphate and its structure is layered, and its particle size is 3 μm) 10%;

[0056] Isothiazolinones (DOCIT) 40%;

[0057] Metal pyridinethione compounds (zinc pyrithione) 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com