Environmentally friendly and long-lasting composite antifouling material

A long-term, anti-fouling technology, applied in anti-fouling/underwater coatings, plant growth regulators, biocides, etc., can solve the problems of short anti-algae anti-fouling life, narrow anti-algae species, and reduced anti-fouling life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] For the above-mentioned layered carrier of the present invention, an embodiment of preparing a slow-release silver loading is listed below, illustrating its preparation process and corresponding beneficial properties: give a general formula of AgZr 2 (PO 4 ) 3 The loading slow-release silver (wherein the weight percentage of silver ion is 3-15%; the weight percentage of zirconium phosphate is 97-85%) is an example, the preparation method includes the following steps: first prepare zirconium phosphate: use soluble zirconium salt (for example: sulfuric acid zirconium oxide, basic zirconium carbonate), phosphoric acid and hydrofluoric acid as raw materials, using conventional fine chemical process, under normal pressure conditions, the reaction temperature is 60-90 ° C, the reaction time is 2-4 hours, and the layered zirconium phosphate inorganic carrier. Then carry out silver complex ion exchange: add zirconium phosphate into the silver nitrate solution and stir for 2-4...

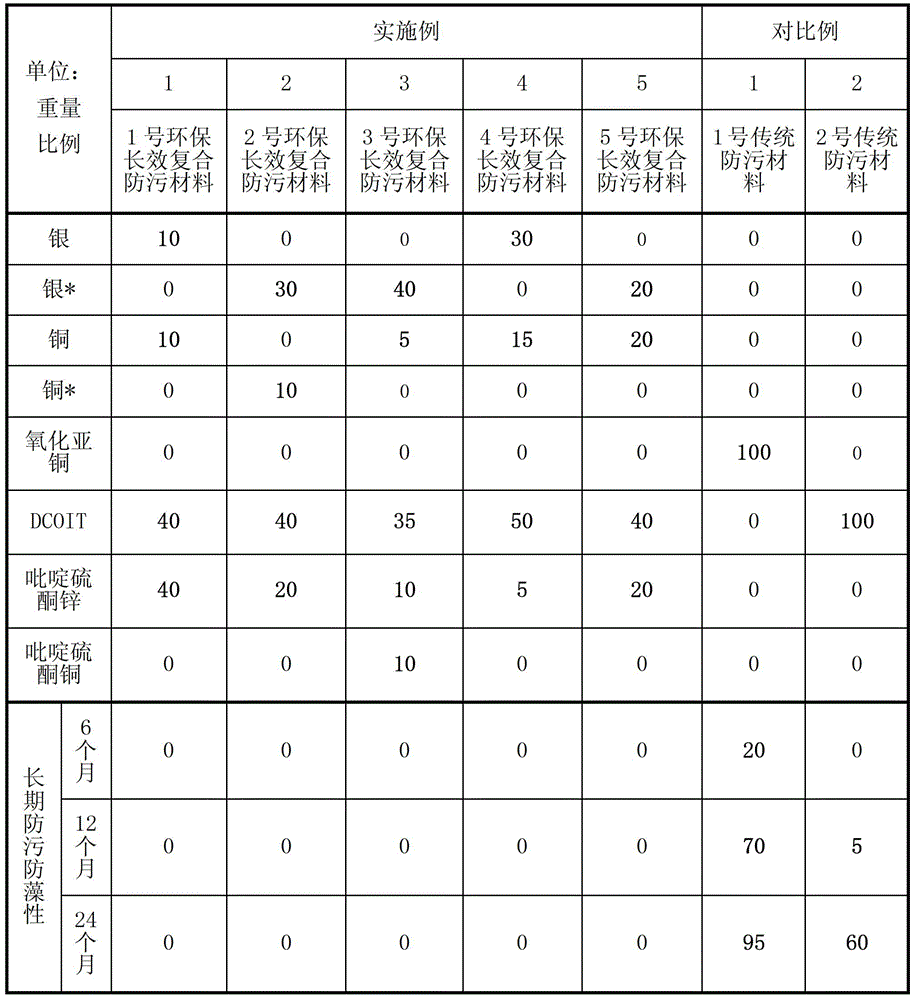

Embodiment 1

[0048] Embodiment 1: represent No. 1 environmental protection long-acting composite antifouling material, its weight percentage consists of:

[0049] Silver (supported slow-release silver, its silver load is 6%, its carrier is zirconium phosphate, particle size is 3μm) 10%;

[0050] Copper (supported slow-release copper, the copper loading is 6%, the carrier is zirconium phosphate, the particle size is 3μm) 10%;

[0051] Isothiazolinone compounds (DOCIT) 40%;

[0052] Metallic pyrithione (zinc pyrithione) 40%.

Embodiment 2

[0053] Embodiment 2: represent No. 2 environmental protection long-acting composite antifouling material, its percentage by weight consists of:

[0054] Silver (supported slow-release silver, its silver load is 3%, its carrier is zirconium phosphate and its structure is layered, the particle size is 3μm) 30%;

[0055] Copper (supported slow-release copper, its copper loading is 3%, its carrier is zirconium phosphate with layered structure, particle size is 3μm) 10%;

[0056] Isothiazolinone compounds (DOCIT) 40%;

[0057] Metallic pyrithione (zinc pyrithione) 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com