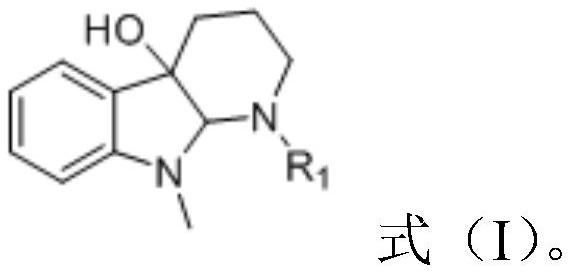

A kind of indole compound, its synthetic method and its antifouling use

A synthesis method and technology of indoles, applied in the fields of botanical equipment and methods, antifouling/underwater coatings, applications, etc., can solve problems such as no detailed reports on antifouling activity, and achieve simple structure and mild reaction conditions. , the effect of high antifouling activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

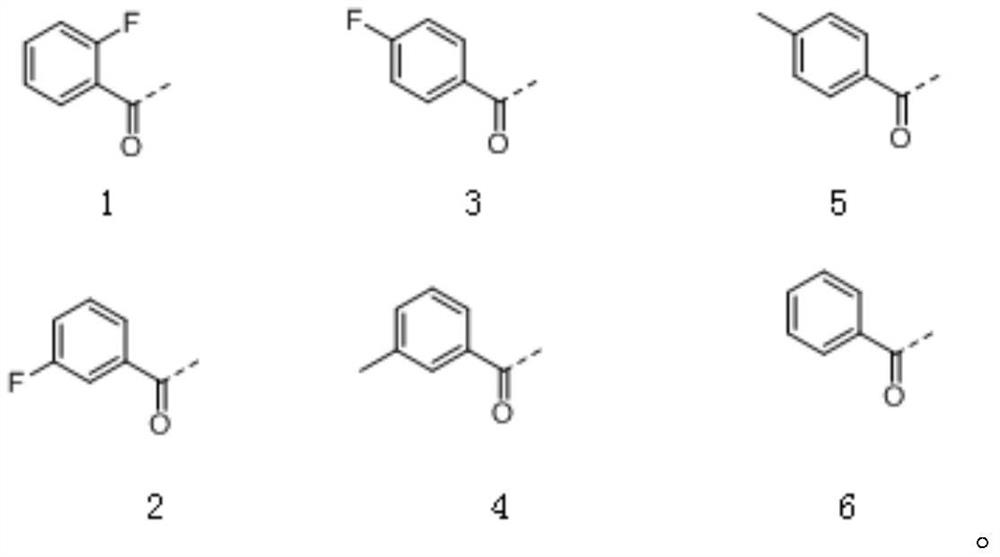

Embodiment 1

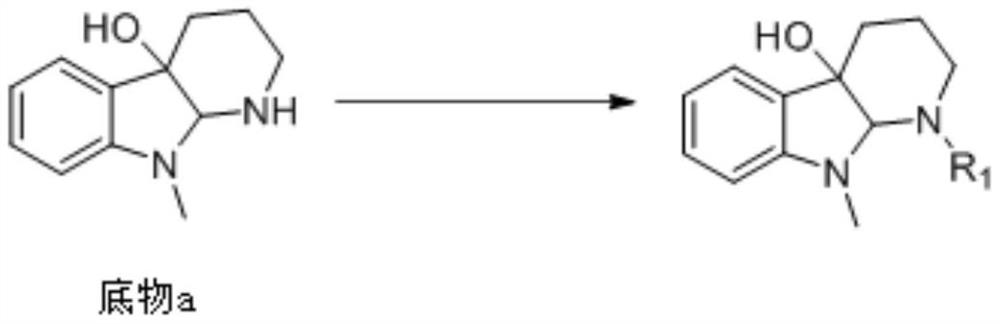

[0021]

[0022] Step (1), first prepared an adjacent fluorophenyl chloride: Take 146 mg (1.2 mmol) of oxfluorobenzoic acid in a dry 25 ml round bottom flask, add 10 ml of anhydrous anhydrous methylenechloromethane, then add The chloride sulfoxide was 0.13 ml (1.8 mmol), heated refluxed for 2 h, evaporated to evaporate dichloromethane and excess of dichloroalkylene sulfoxide under reduced pressure.

[0023] Step (2), weigh 200 mg of substrate a, placed in a 25 ml dry round bottom flask, and mixed 10 ml of anhydrous methylene chloroform and dissolve, 0.90 mmol of 0.90 mmol), stirred for 20 minutes. In the ice water bath placed at 0 ° C, the methyl chloride solution of the benzoyl chloride was slowly added dropwise, and the reaction liquid was stirred at room temperature for 2 h, TLC (PE: EA = 4: 1) detection The substrate reaction is complete. Add an appropriate amount of saturated NaHCO to the reaction liquid 3 The reaction was quenched. The organic phase was extracted 3 times wi...

Embodiment 2

[0031]

[0032] White oil, 1 H-NMR (400MHz, CDCL 3 ), δ7.98-6.99 (m, 6H), 6.88-6.39 (m, 2H), 5.66-4.01 (M, 1H), 3.66-3.17 (m, 1H), 3.10 (DT, J = 12.9, 6.1Hz, 1H), 2.64 (S, 3H), 2.56-0.84 (M, 2H), 1.56-0.84 (M, 2H) .13C NMR (100 MHz, CDCL3) δ171.52 ( C), 164.58 (C), 148.86 (C), 137.70 (CH), 125.85 (CH), 123.58 (CH), 122.10 (CH), 120.40 (CH), 119.43 ( CH), 117.06 (CH), 115.01 (CH), 108.24 (CH), 86.74 (C), 43.19 (CH2), 38.25 (CH3), 34.19 (CH2), 18.29 (CH2).

[0033] MS (ESI (+)) Calcd for C 19 Hide 19 FN 2 O 2 [M + h] + : 326.4; Found: 327.0.

Embodiment 3

[0035]

[0036] Colorless oil, 1 H-NMR (400MHz, CDCL 3), δ7.74-7.37 (m, 2H), 7.25-6.95 (m, 4H), 6.88-6.32 (M, 2H), 5.28 (S, 1H), 4.43-4.00 (m, 1H), 3.64-3.16 (M, 1H), 3.14 -2.79 (m, 3H), 2.60 (m, 2H), 2.09-1.22 (m, 1H), 1.57-1.22 (m, 1H). 13C NMR (100MHz, CDCL3) Δ172.16 (C), 163.35 (C), 148.92 (C), 133.43 (C), 132.32 (C), 131.63 (CH), 130.24 (CH), 130.15 (CH), 129.64 (CH), 129.39 (CH), 122.15 (CH), 119.32 (CH), 115.65 (CH), 108.13 (CH), 86.84 (C), 43.31 (CH2), 38.35 (CH3), 34.16 (CH2), 18.24 (CH2).

[0037] MS (ESI (+)) Calcd for C 19 Hide 19 FN 2 O 2 [M + h] + : 326.4; Found: 327.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com