Preparation method of resveratrol-loaded and amino-modified mesoporous silica nanoparticles

A technology of mesoporous silica and amino modification, applied in the direction of active ingredients of hydroxyl compounds, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve the problems of unstable physical and chemical properties, insoluble in water, short half-life, etc. Achieve the effect of improving bioavailability, good market prospects, and increasing drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1 Instruments and materials

[0022] 1.1 Instrument

[0023] Waters high performance liquid chromatograph (Waters e2695 quaternary pump, 2998 PDA detector, U.S. Waters company);

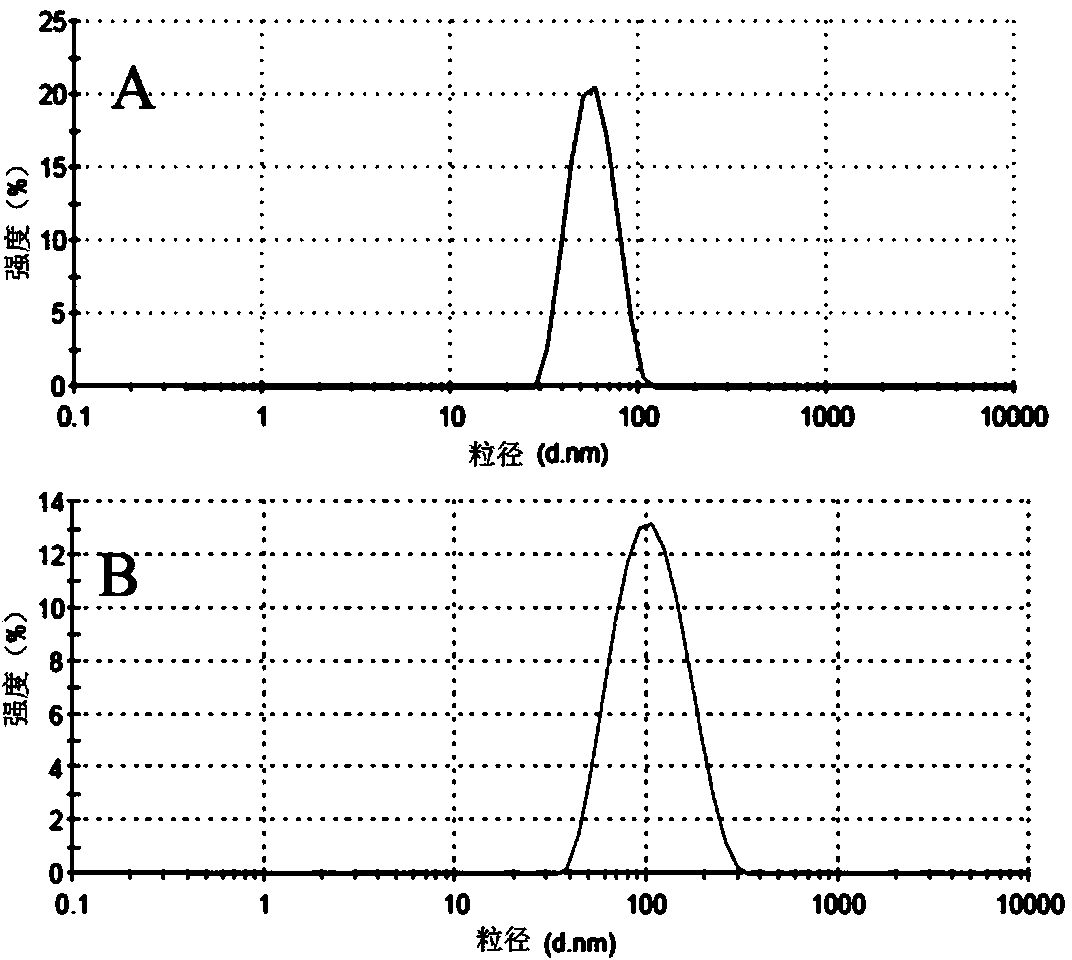

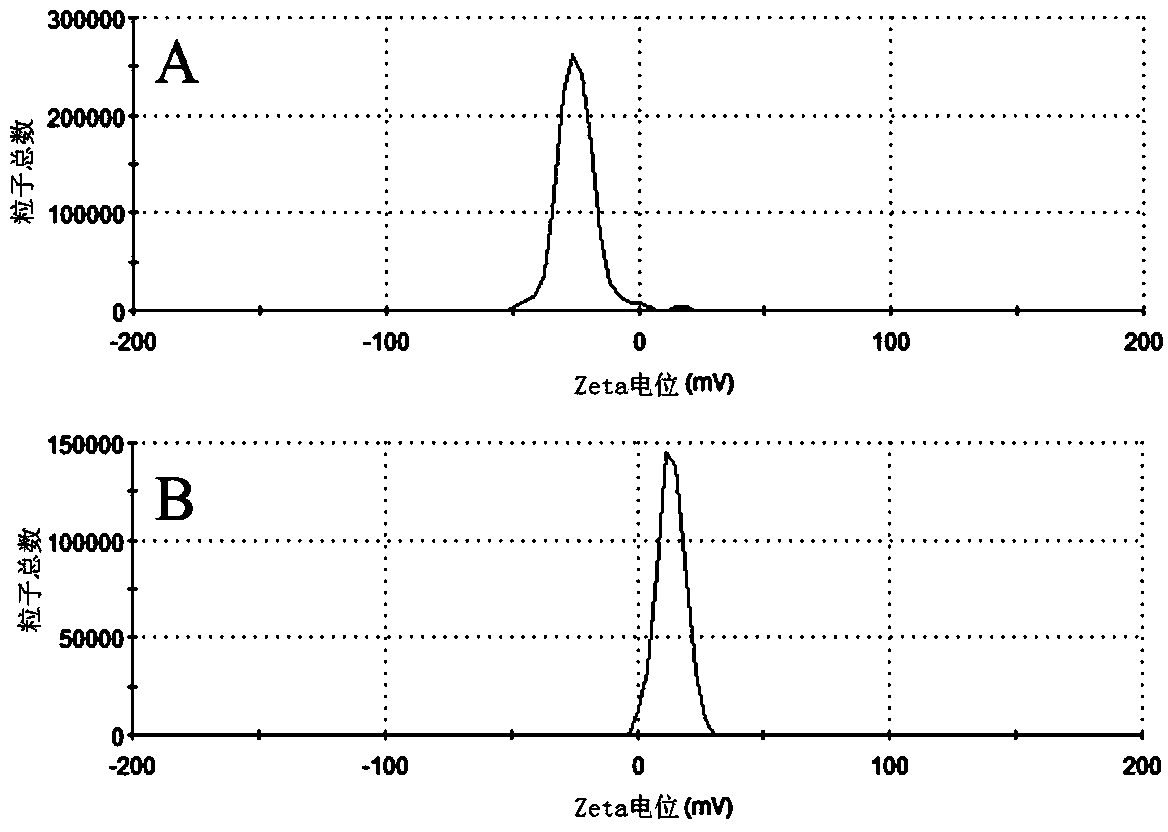

[0024] Nano-ZS 90 laser particle size analyzer (Malvern Instrument Co., Ltd., UK);

[0025] Optima MAX ultra-low temperature centrifuge (Beckman Coulter Co., Ltd., USA);

[0026] Mill-Q ultrapure water meter (Millpore, USA);

[0027] PH acidity meter (Switzerland Mettler-Toledo company);

[0028] JEM-1200EX transmission electron microscope (Japan JEOL company);

[0029] Vector 22 Fourier transform infrared spectrometer (Germany BRUKER company);

[0030] TRISTAR II3020 automatic specific surface and pore analyzer (Micromeritics Instrument Company, USA);

[0031] Rigaku D / max 2550PC automatic polycrystalline X-ray diffractometer (Japan Rigaku Electric Co., Ltd.);

[0032] Thermo Forma ultra-low temperature refrigerator (U.S. Thermo Fisher Scientific company);

[0033] TGL-16B high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com