Heating and thermal insulation riser sleeve

A technology of thermal insulation riser sleeve and thermal insulation layer, which is applied in the field of alloy casting, can solve the problems of feeding resistance, flexibility and adaptability of thermal insulation riser sleeve, etc., and achieves simple shape and structure, convenient standardization and assembly line production. The effect of the riser feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

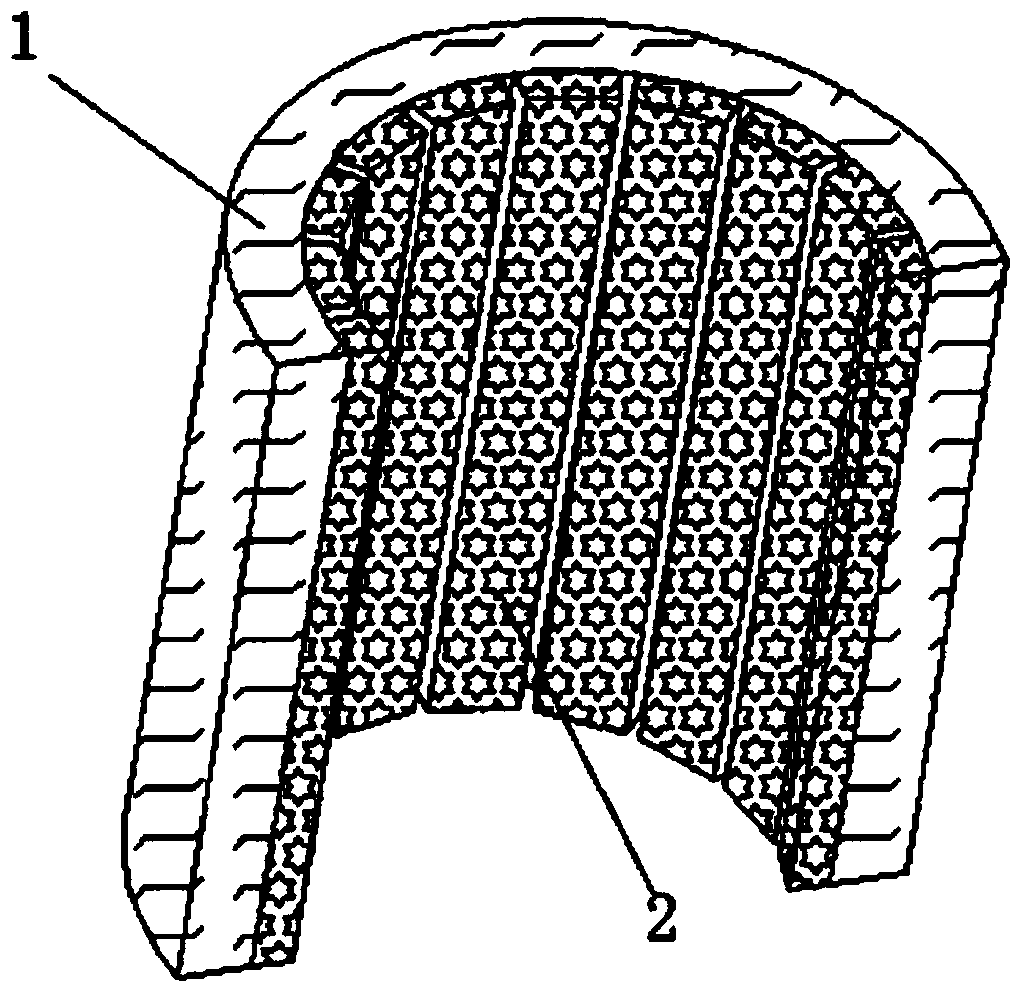

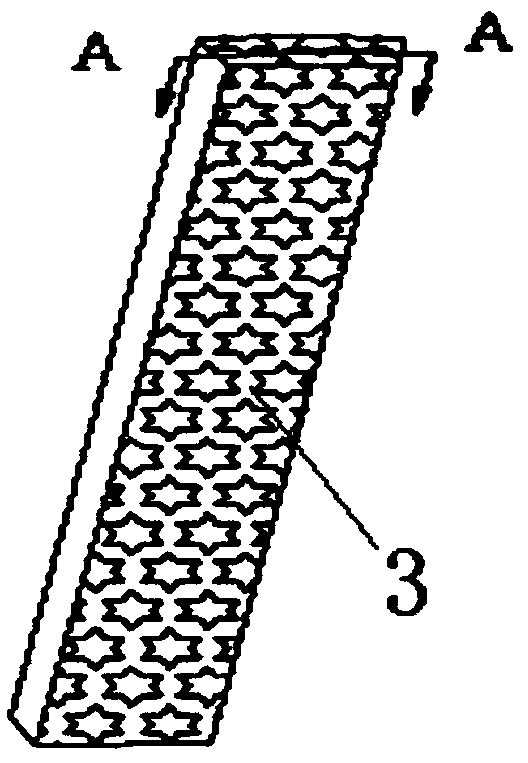

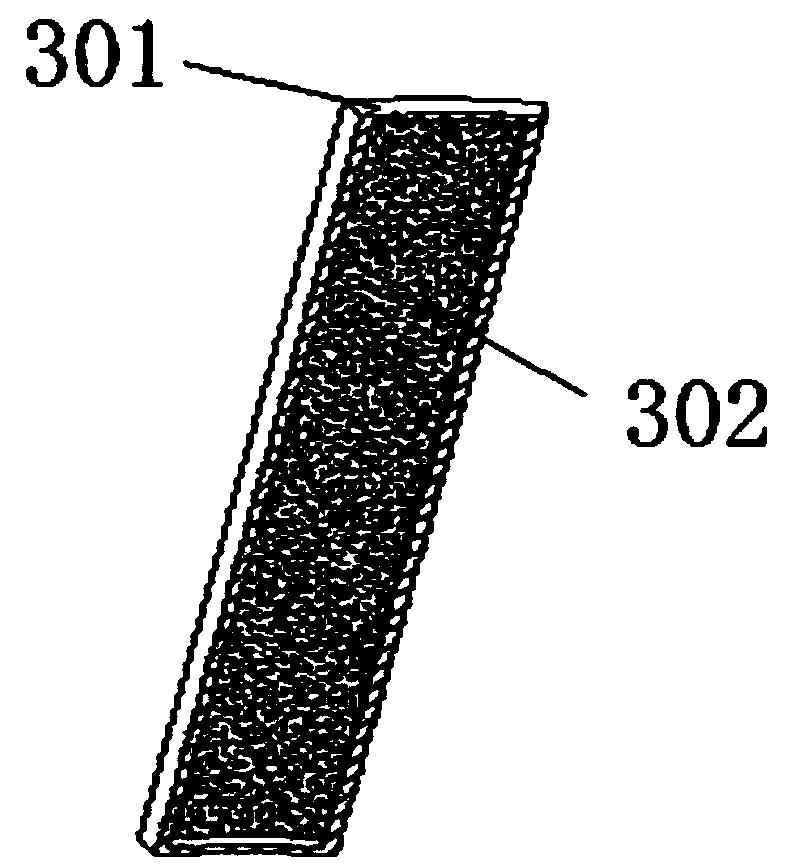

[0024] A heating and heat preservation riser sleeve, comprising a thermal insulation layer 1 and a heating layer 2, the heating layer 2 is composed of several heating packs 3, and the heating packs 3 also include a heating agent layer 302 and a coating layer 301, the heating agent Layer 302 is 9 parts by weight of edible starch or calcium lignosulfonate powder, 11 parts by weight of potassium permanganate, 48 parts by weight of charcoal powder and 32 parts by weight of magnesium powder, fully mixed and pressed into a flat, thick It is a long block-shaped heating pack of 5 mm to 8 mm. According to the type of riser used, the type of insulation layer 1 is also different. The heating agent can be pressed into various specifications and wrapped in kraft paper to make a heating pack 3 for later use; Layer 1 is made of refractory insulation materials such as calcium silicate or aluminum silicate ceramic fiber. Place the thermal insulation base material of the thermal insulation laye...

Embodiment 2

[0027] A heating and heat preservation riser sleeve, comprising a thermal insulation layer 1 and a heating layer 2, the heating layer 2 is composed of several heating packs 3, and the heating packs 3 also include a heating agent layer 302 and a coating layer 301, the heating agent Layer 302 is 11 parts by weight of edible starch or calcium lignosulfonate powder, 9 parts by weight of potassium permanganate, 52 parts by weight of charcoal powder and 28 parts by weight of magnesium powder, which are fully mixed and pressed into a flat, thick It is a long block-shaped heating pack of 5 mm to 8 mm. According to the type of riser used, the type of insulation layer 1 is also different. The heating agent can be pressed into various specifications and wrapped in kraft paper to make a heating pack 3 for later use; Layer 1 is made of refractory insulation materials such as calcium silicate or aluminum silicate ceramic fiber. Place the thermal insulation base material of the thermal insul...

Embodiment 3

[0030] A heating and heat preservation riser sleeve, comprising a thermal insulation layer 1 and a heating layer 2, the heating layer 2 is composed of several heating packs 3, and the heating packs 3 also include a heating agent layer 302 and a coating layer 301, the heating agent Layer 302 is 10 parts by weight of edible starch or calcium lignosulfonate powder, 10 parts by weight of potassium permanganate, 50 parts by weight of charcoal powder and 30 parts by weight of magnesium powder, which are fully mixed and pressed into a flat shape with a thickness of It is a long block-shaped heating pack of 5 mm to 8 mm. According to the type of riser used, the type of insulation layer 1 is also different. The heating agent can be pressed into various specifications and wrapped in kraft paper to make a heating pack 3 for later use; Layer 1 is made of refractory insulation materials such as calcium silicate or aluminum silicate ceramic fiber. Place the thermal insulation base material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com