Water-based solar heat-reflecting paint and preparation method thereof

A technology of solar heat and reflective coatings, applied in the field of solar materials, can solve problems such as production and living inconvenience, increased energy consumption, and potential safety hazards, and achieve the effects of hardness water-based environmental protection, good weather resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

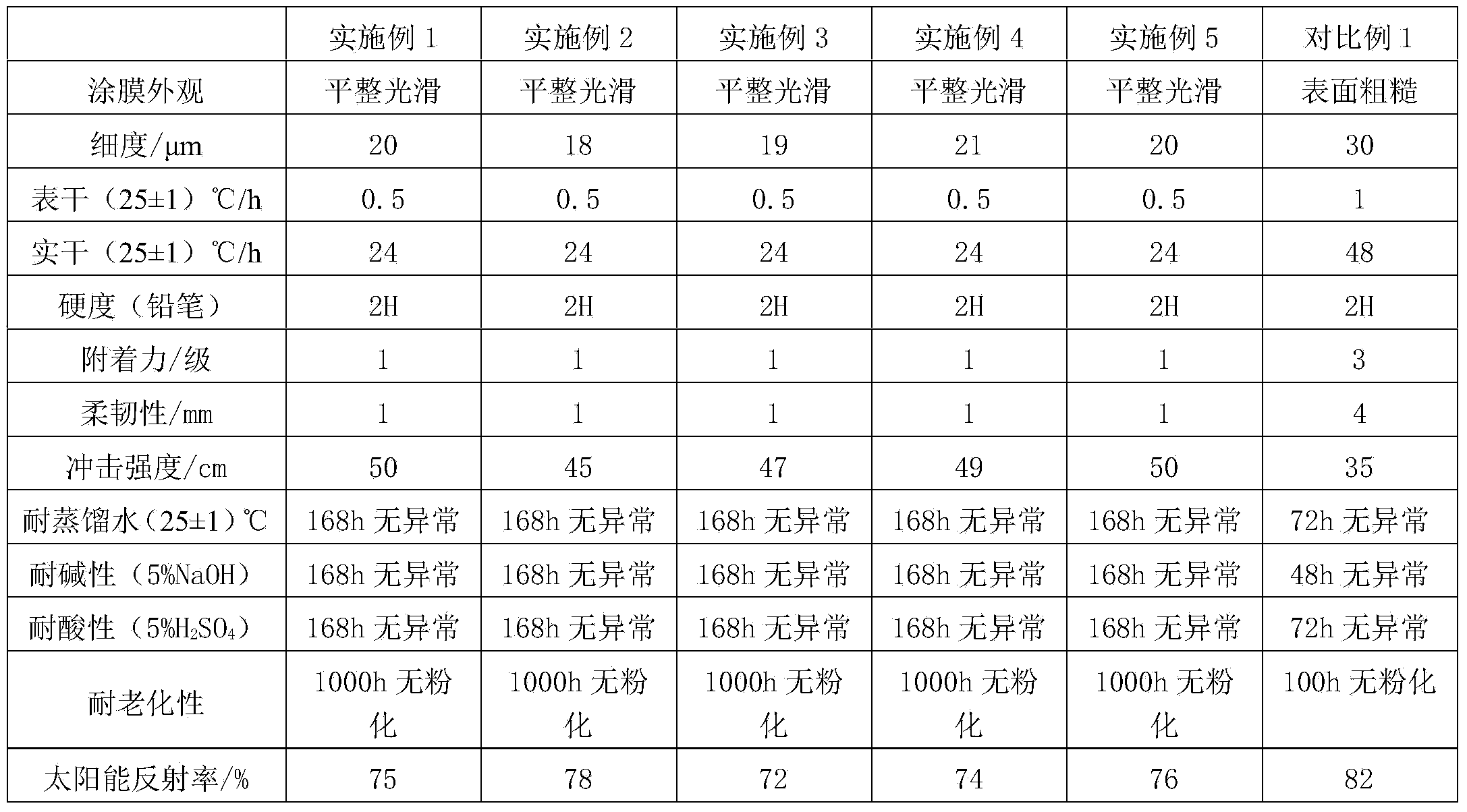

Examples

Embodiment 1

[0020] A water-based solar thermal reflective coating. The raw materials include 3 parts by weight of chlorosulfonated polyethylene, 2 parts of glass flakes, 1 part of phenolic epoxy resin, 2 parts of water-based hydroxy acrylic resin, and 42 parts of polyvinyl butyral. , 5 parts of aluminum tripolyphosphate, 2 parts of ethyl orthosilicate, 1 part of aluminum silicate fiber, 3 parts of polydimethylsiloxane, 4 parts of diisobutyl phthalate, 1 part of extender pigment, anti-mold 2 parts of agent and 10 parts of deionized water.

[0021] The above-mentioned extender pigment is titanium dioxide; the anti-mold agent is sodium pentachlorophenate.

[0022] The preparation method of the above-mentioned water-based solar thermal reflective paint includes the following steps:

[0023] Step 1. Add the chlorosulfonated polyethylene, glass flakes, phenolic epoxy resin, water-based hydroxy acrylic resin and deionized water to the grinder, grind until the particle size of the mixed liquid is 250 μ...

Embodiment 2

[0027] A water-based solar thermal reflective coating. The raw materials in parts by weight include: 5 parts of chlorosulfonated polyethylene, 4 parts of glass flakes, 3 parts of phenolic epoxy resin, 4 parts of water-based hydroxy acrylic resin, and 6 parts of polyvinyl butyral. , 6 parts of aluminum tripolyphosphate, 3 parts of ethyl orthosilicate, 3 parts of aluminum silicate fiber, 5 parts of dimethicone, 6 parts of diisobutyl phthalate, 2 parts of extender pigment, anti-mold 3 parts of agent and 14 parts of deionized water.

[0028] The above-mentioned extender pigment is zinc oxide; the anti-mold agent is phenylmercury acetate.

[0029] The preparation method of the above-mentioned water-based solar thermal reflective paint includes the following steps:

[0030] Step 1. Add the chlorosulfonated polyethylene, glass flakes, phenolic epoxy resin, water-based hydroxy acrylic resin and deionized water to the grinder, grind until the particle size of the mixed liquid is 200 μm, and ...

Embodiment 3

[0034] A water-based solar thermal reflective coating. The raw materials include: 7 parts by weight of chlorosulfonated polyethylene, 5 parts of glass flakes, 4 parts of phenolic epoxy resin, 6 parts of water-based hydroxy acrylic resin, and 9 parts of polyvinyl butyral. , 7 parts of aluminum tripolyphosphate, 5 parts of ethyl orthosilicate, 4 parts of aluminum silicate fiber, 6 parts of dimethicone, 8 parts of diisobutyl phthalate, 3 parts of extender pigment, anti-mold 5 parts of agent and 19 parts of deionized water.

[0035] The above-mentioned extender pigment is aniline black; the anti-mold agent is 1,2-benzisothiazolin-3-one.

[0036] The preparation method of the above-mentioned water-based solar thermal reflective paint includes the following steps:

[0037] Step 1. Add the chlorosulfonated polyethylene, glass flakes, phenolic epoxy resin, water-based hydroxy acrylic resin and deionized water to the grinder, grind until the particle size of the mixed liquid is 220 μm, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com