A kind of aluminum base powder metallurgy composite material and preparation method thereof

A technology for powder metallurgy and composite materials, applied in the field of powder metallurgy composite materials and their preparation, can solve the problems of low elastic modulus, tensile strength and elongation of aluminum alloys, and achieve the promotion of interface bonding, wide application range and comprehensive performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

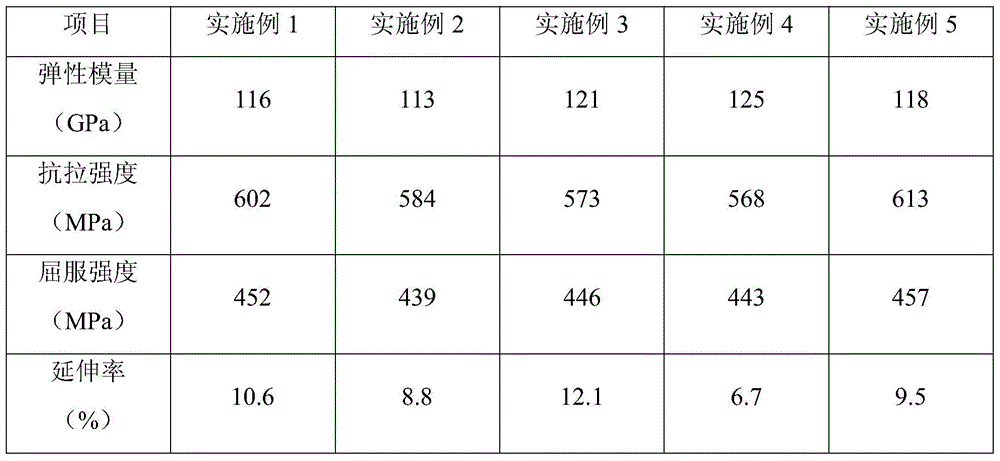

Examples

Embodiment 1

[0020] An aluminum-based powder metallurgy composite material is composed of the following substances in weight percentage: carbon nanotube 0.6%, silicon 6%, bismuth 0.1%, manganese 3.5%, magnesium 1.2%, titanium 1.5%, chromium 0.5%, boron oxide 0.3% , Beryllium 0.2%, the balance is aluminum.

[0021] A method for preparing an aluminum-based powder metallurgy composite material, comprising the following steps:

[0022] a: Weigh silicon, bismuth, manganese, magnesium, titanium, chromium, boron oxide, beryllium and aluminum according to the weight percentage, and mix them uniformly for 12 hours with a mechanical ball mill mixer to form a uniform mixed powder for later use;

[0023] b: put the carbon nanotubes into absolute ethanol and ultrasonically shake for 15 minutes to fully stir, then add to the mixed powder obtained in step a, and stir for another 20 minutes to obtain a uniformly stirred mixture;

[0024] C, the mixture that step b obtains is 120kgf / cm under pressure 2 a...

Embodiment 2

[0026] An aluminum-based powder metallurgy composite material is composed of the following substances in weight percentage: carbon nanotube 4.8%, silicon 8.5%, bismuth 0.2%, manganese 4.5%, magnesium 2.5%, titanium 2.7%, chromium 1.4%, boron oxide 1% , Beryllium 0.5%, the balance is aluminum.

[0027] A method for preparing an aluminum-based powder metallurgy composite material, comprising the following steps:

[0028] a: Weigh silicon, bismuth, manganese, magnesium, titanium, chromium, boron oxide, beryllium and aluminum according to weight percentage, and mix them uniformly with a mechanical ball mill mixer for 14 hours to form a uniform mixed powder for later use;

[0029] b: put the carbon nanotubes into absolute ethanol and ultrasonically shake for 18 minutes to fully stir, then add to the mixed powder obtained in step a, and stir for another 25 minutes to obtain a uniformly stirred mixture;

[0030] C, the mixture that step b obtains is 122kgf / cm under pressure 2 and s...

Embodiment 3

[0032] An aluminum-based powder metallurgy composite material is composed of the following substances in weight percentage: carbon nanotube 1%, silicon 7%, bismuth 0.12%, manganese 3.7%, magnesium 1.5%, titanium 1.8%, chromium 0.8%, boron oxide 0.5% , Beryllium 0.3%, the balance is aluminum.

[0033] A method for preparing an aluminum-based powder metallurgy composite material, comprising the following steps:

[0034] a: Weigh silicon, bismuth, manganese, magnesium, titanium, chromium, boron oxide, beryllium and aluminum according to weight percentage, and uniformly mix them with a mechanical ball mill mixer for 16 hours to form a uniform mixed powder for later use;

[0035] b: put the carbon nanotubes into absolute ethanol and ultrasonically shake for 22 minutes to fully stir, then add to the mixed powder obtained in step a, and stir for another 35 minutes to obtain a uniformly stirred mixture;

[0036] C, the mixture that step b obtains is 128kgf / cm under pressure 2 and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com