Dry-process spandex spinning oil agent

A technology of dry spinning and spinning oil, which is applied in the direction of textiles and papermaking, single-component synthetic polymer rayon, chemical post-treatment of synthetic polymer rayon, etc., which can solve the discomfort of human body and unfavorable equipment maintenance , no other functional problems, etc., to achieve good antistatic, good unwinding performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

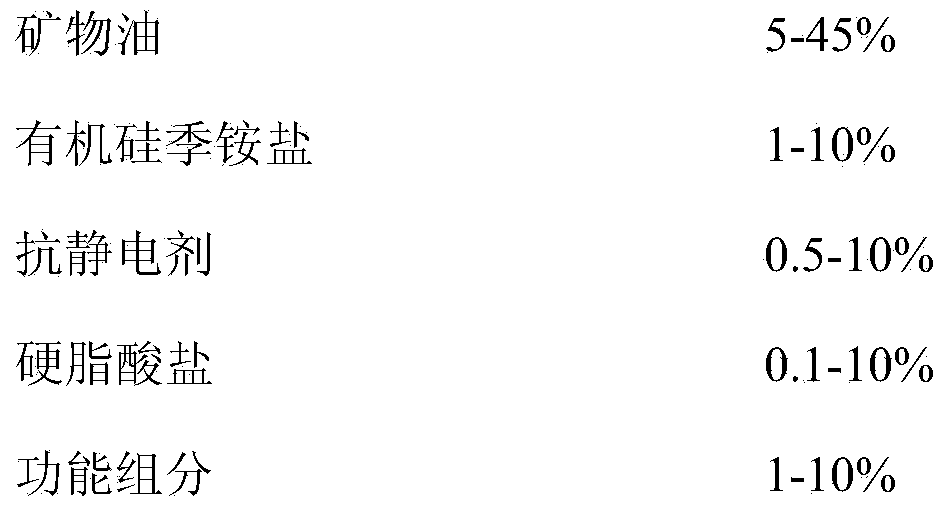

[0022] Respectively the simethicone oil of 35.5% by weight, the mineral oil of 45% by weight, the polysiloxane quaternary ammonium salt of 2.5% by weight, the fatty alcohol polyoxyethylene ether of 10% by weight, the zinc stearate of 5% by weight, 2% by weight of Artemisia argyi extract was added into a glass reactor, heated to 80° C. in a nitrogen atmosphere, stirred continuously for 60 minutes, and then naturally cooled to room temperature.

Embodiment 2

[0024] The simethicone oil of 30% by weight, the mineral oil of 41% by weight, the polysiloxane quaternary ammonium salt of 6% by weight, the fatty alcohol polyoxyethylene ether of 9% by weight, the zinc stearate of 6% by weight, 8% by weight of Artemisia argyi extract was added to a glass reactor, heated to 80° C. in a nitrogen atmosphere, stirred continuously for 70 minutes, and then naturally cooled to room temperature.

Embodiment 3

[0026] Respectively the simethicone oil of 26% by weight, the mineral oil of 45% by weight, the polysiloxane quaternary ammonium salt of 8% by weight, the fatty alcohol polyoxyethylene ether of 8% by weight, the zinc stearate of 5% by weight, 8% by weight of leaves of mugwort, peppermint, mosquito repellent and lavender are added in a glass reactor, heated to 70° C. in a nitrogen environment, continuously stirred for 80 minutes, and then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com