Laminate

A technology of laminates and silicon-containing layers, applied in the directions of coating, lamination, layered products, etc., can solve the problem of insufficient barrier properties, and achieve excellent flexural resistance, high oxygen barrier properties and water vapor barrier properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

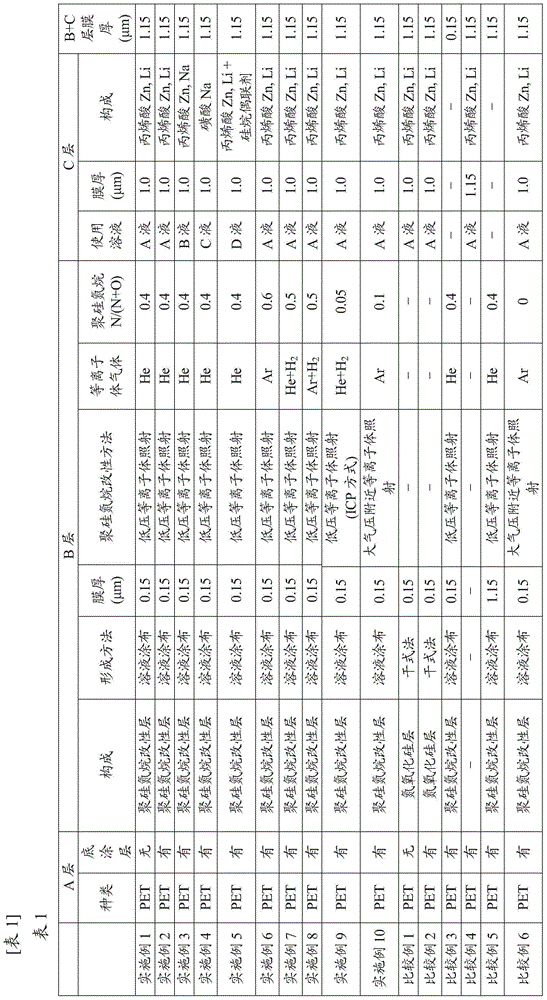

[0244] Polysilazane (NL110A , AZ ELECTRONIC MATERIALS Co., Ltd.) 4.5 wt% xylene (dehydrated) solution was dried at 150° C. for 90 seconds to produce a polysilazane film with a thickness of 0.15 μm.

[0245] This polysilazane film was subjected to low-pressure plasma treatment under the following conditions to form a silicon-containing layer (B).

[0246] Vacuum plasma processing device: Low-voltage capacitively coupled plasma processing device (manufactured by YOUTEC Co., Ltd.)

[0247] Gas: He

[0248] Gas flow: 50mL / min

[0249] Pressure: 19Pa

[0250] Applied power per electrode unit area: 1.3W / cm 2

[0251] Frequency: 13.56MHz

[0252] Processing time: 30 seconds

[0253] Oxygen concentration: below 1ppm

[0254] Water vapor concentration: below 1ppm

[0255] Then, on the silicon-containing layer (B) made with 2.8g / m 2 The above-mentioned solution (A) was applied in an amount of , and dried using a hot air dryer at a temperature of 60° C. for 30 seconds. Then, i...

Embodiment 2

[0259] Polyurethane acrylate (urethane acrylate UV-like curing coating material (trade name UA-100 manufactured by Shin-Nakamura Chemical Co., Ltd.), using a Meyer rod to 1.2g / m 2 (solid content) was applied, and dried at 100° C. for 15 seconds. Then, using a UV irradiation device (EYE GRANDAGE model ECS 301G1 manufactured by EyeGraphic Co., Ltd.), at a UV intensity of 250 mW / cm 2 , Cumulative light intensity is 117mJ / cm 2 Under certain conditions, the coated surface is light-cured, and the primer layer is set. Furthermore, a 4.5wt% xylene (dehydrated) solution of polysilazane (NL110A, manufactured by AZ ELECTRONIC MATERIALS Co., Ltd.) was coated thereon by bar coating, and dried at 150° C. for 90 seconds to produce a 0.15 μm-thick film. polysilazane film. Then, the same operation as in Example 1 was performed to obtain a laminated body. Table 1 shows the measurement results of physical properties of the obtained laminate.

Embodiment 3

[0261] Except having changed the solution A used in Example 2 into solution B, it carried out similarly to Example 2, and obtained the laminated body. Table 1 shows the measurement results of physical properties of the obtained laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com