Sweet egg paste and preparation method thereof

An egg cheese and egg technology, which is applied in comprehensive processing, whole egg liquid product processing, restriction enzyme hydrolysis, egg egg cheese and its preparation fields, can solve the problems of single variety, long production cycle and high price, and achieve increased solubility , the effect of more products and increased number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

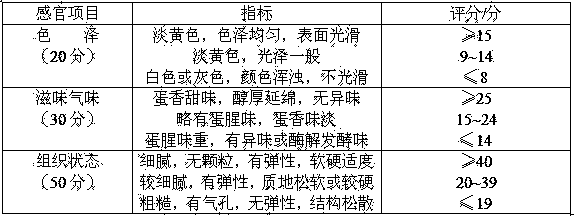

Examples

Embodiment 1

[0032] A method for preparing egg custard, characterized in that it is prepared according to the following steps:

[0033] (1) Select fresh eggs, remove the shells to obtain whole egg liquid, stir the whole egg liquid at a speed of 150-200rpm, filter to obtain uniform whole egg liquid, and set aside;

[0034] (2) Add the same amount of pure water to the whole egg liquid described in step (1) to prepare a certain egg-water mixture, and add 0.05% papain and 0.003% flavor protease to the egg-water mixture in terms of mass percentage , the enzymolysis conditions are pH 6.5, temperature 55°C, hydrolysis for 1 hour, stirring at low speed during the enzymolysis process, controlling the hydrolyzed DH at 5, killing the enzyme, and obtaining a protein solution with a low degree of hydrolysis after pasteurization, for later use; papain The activity of the compound flavor protease is 5000U / g, and the activity of the compound flavor protease is 3000U / g;

[0035] (3) Add lactose, which acc...

Embodiment 2

[0040] A method for preparing egg custard, characterized in that it is prepared according to the following steps:

[0041] (1) Select fresh eggs, remove the shells to obtain whole egg liquid, stir the whole egg liquid at a speed of 150-200rpm, filter to obtain uniform whole egg liquid, and set aside;

[0042] (2) Add the same amount of pure water to the whole egg liquid described in step (1) to prepare a certain egg-water mixture. In terms of mass percentage, add 0.06% papain and 0.005% flavor protease to the egg-water mixture , the enzymolysis conditions are pH 6.8, temperature 57°C, hydrolysis for 1.2h, stirring at low speed during the enzymolysis process, controlling the hydrolyzed DH at 6, killing the enzyme, and obtaining a protein solution with a low degree of hydrolysis after pasteurization, for later use; papaya The activity of protease is 5000U / g, and the activity of compound flavor protease is 3000U / g;

[0043] (3) Add lactose accounting for 4% of the mass of the lo...

Embodiment 3

[0048] A method for preparing egg custard, characterized in that it is prepared according to the following steps:

[0049] (1) Select fresh eggs, remove the shells to obtain whole egg liquid, stir the whole egg liquid at a speed of 150-200rpm, filter to obtain uniform whole egg liquid, and set aside;

[0050] (2) Add the same amount of pure water to the whole egg liquid described in step (1) to prepare a certain egg-water mixture, and add 0.08% papain and 0.006% flavor protease to the egg-water mixture in terms of mass percentage , the enzymolysis conditions are pH 7.0, temperature 60°C, hydrolysis for 1.5h, stirring at low speed during the enzymolysis process, controlling the hydrolyzed DH at 8, killing the enzyme, and obtaining a protein solution with a low degree of hydrolysis after pasteurization, for later use; papaya The activity of protease is 5000U / g, and the activity of compound flavor protease is 3000U / g;

[0051] (3) Add 6% lactose to the protein liquid with low de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com