Naphthyl methyl imidazole modified silica gel adsorbent and preparation method and application of naphthyl methyl imidazole modified silica gel adsorbent

A naphthylmethylimidazole, silica gel adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of failing to give full play to the designability of ionic liquids, lack of structure and performance relationship, etc. , to achieve the effect of novel structure, high enrichment factor and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add the solution of imidazole (2.119g, 31mmol) in 1,4-dioxane (50mL) to the suspension of oil-free NaH (1.364g, 34mmol) in 1,4-dioxane (100mL) , stirred at 90°C for 1h, then added 1-chloromethylnaphthalene (5g, 28mmol) in 1,4-dioxane (50mL) dropwise to the above solution, and stirred the mixed solution at 90°C for 22h to prepare Brown solution, remove the solvent by rotary evaporation, add 100mL distilled water to the residue, wash with CH 2 Cl 2 (3*50mL) extraction, extract with anhydrous MgSO 4 Dry, rotary evaporate to remove CH 2 Cl 2 Afterwards, the product 1-(1-naphthylmethyl)imidazole was obtained.

[0023]

[0024] (2) Mix 3-chloropropyltriethoxysilane and 1-(1-naphthylmethyl)imidazole at a molar ratio of 1:1.2, then react at 80°C for 24 hours to obtain 1-(1-naphthalene Methyl)-3-triethoxysilylpropylimidazole.

[0025]

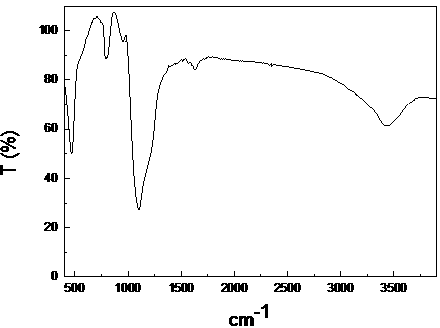

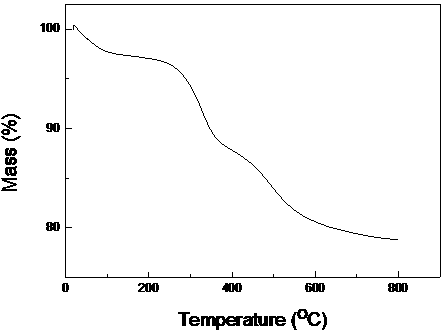

[0026] (3) React 5g of activated silica gel with 4.2g of 1-(1-naphthylmethyl)-3-triethoxysilylpropylimidazole in toluene (60mL) ...

Embodiment 2

[0034] Adsorption selectivity experiment

[0035] Experimental conditions: mass of naphthalenemethylimidazole modified silica gel adsorbent: 25mg, initial concentration of phenol solution: 50mg / L, solution volume: 50mL, temperature: 30°C, stirring speed: 160rpm, time: 3h. Table 1 shows the adsorption results of the naphthalenemethylimidazole-modified silica gel adsorbent on different phenolic substances under the same conditions. As shown in Table 1, the naphthalenemethylimidazole-modified silica gel adsorbent selectively adsorbs 2,4-dinitrophenol, And the adsorption capacity is large.

[0036] Table 1 Adsorption results of different phenols by naphthalenemethylimidazole modified silica gel adsorbent under the same conditions

[0037] Adsorbent Adsorption capacity (mg / g) 2,4-Dinitrophenol 66.2 p-Chlorophenol 14.7 3-Aminophenol 14.5 1-naphthol 13.6 2-naphthol 9.38 2-Nitrophenol 7.74 3-Nitrophenol 1.42 4-Nitrophenol 10...

Embodiment 3

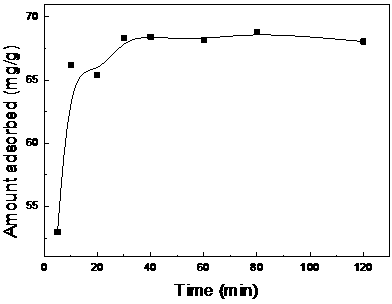

[0039] Adsorption Kinetic Analysis

[0040] Experimental conditions: mass of naphthalenemethylimidazole modified silica gel adsorbent: 25mg, initial concentration of 2,4-dinitrophenol solution: 50mg / L, solution volume: 50mL, temperature: 30°C, stirring speed: 160rpm. Such as image 3 It can be seen that the adsorption rate of 2,4-dinitrophenol on the silica gel adsorbent modified by naphthalenemethylimidazole is fast, and the adsorption capacity reaches 66 mg / g in 10 minutes, which is close to the saturated adsorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com