Method for preparing Sm2Fe17Nx magnetic powder by taking ammonium carbonate as nitrogen source positive pressure samarium iron nitride alloy

A technology of samarium-iron nitride and ammonium carbonate, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of uneven distribution of nitrogen atoms, low utilization rate of nitrogen source, and low degree of nitriding, so as to improve the uniformity of composition properties, uniform composition, and sufficient nitriding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

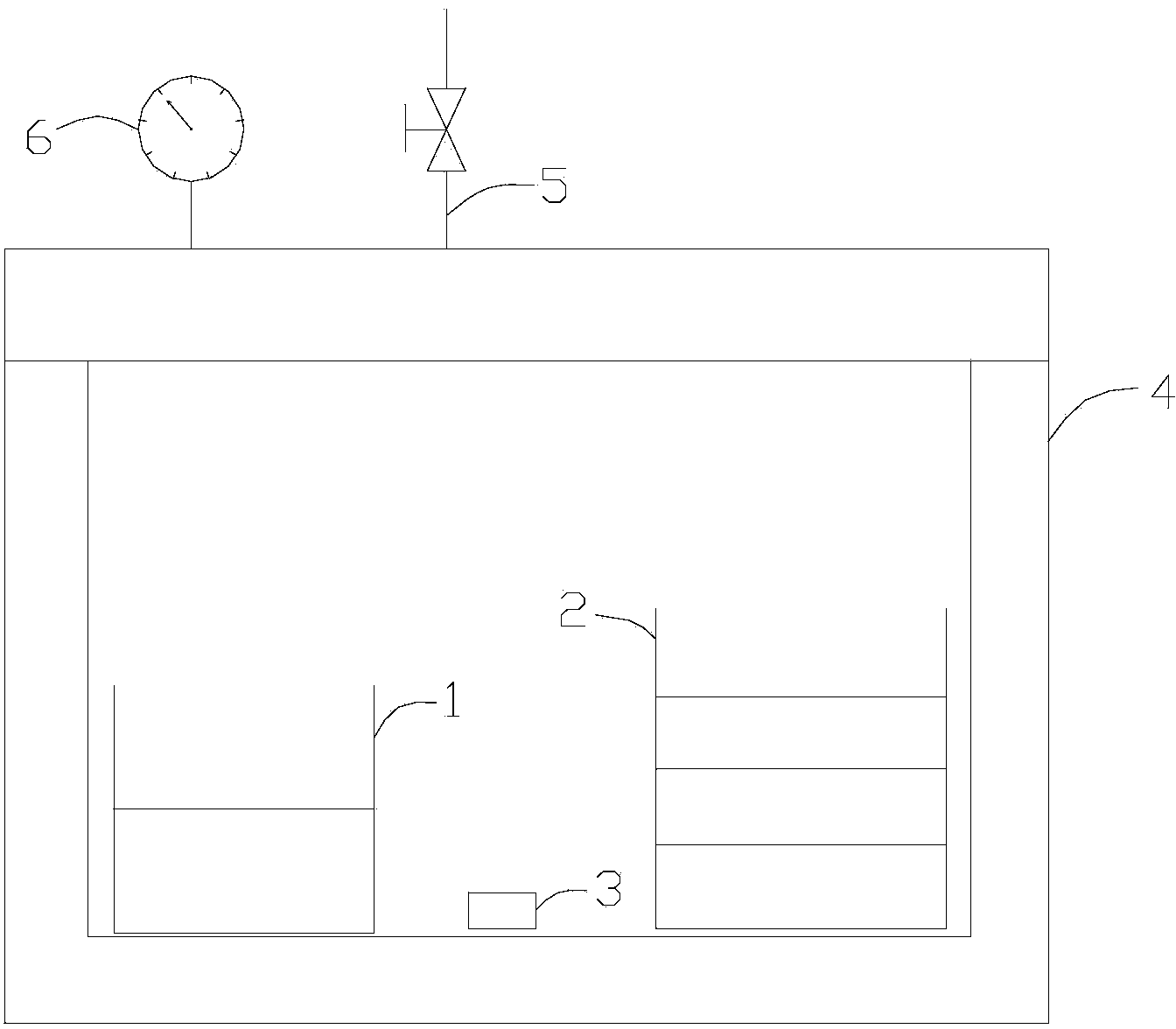

[0040] (1) First put 6g of samarium-iron alloy powder into crucible 1, put 1.90g of ammonium carbonate solid, 2.0g of sodium hydroxide and 5g of calcium oxide into crucible 2 in order from bottom to top, and put 0.1g of metal calcium particles into crucible 2. into container 3;

[0041] (2) Then put the crucible 1 and the crucible 2 in a temperature-resistant and pressure-resistant container 4 with a volume of 200ml. ) vacuum, vacuum degree ≤ 0.05MPa;

[0042] (3) Then the crucible 2 is heated to thermally decompose the ammonium carbonate; simultaneously, the crucible 1 is heated to 70° C., and kept for 60 minutes, then heated to 380° C. for nitriding, and kept for 2 hours; cooled to 350° C. for homogenization heat treatment, Homogenization heat treatment for 4h; finally lowered to room temperature to obtain Sm 2 Fe 17 N x magnetic powder.

[0043] Assuming that the increase in the mass of the magnetic powder is only related to the introduction of nitrogen atoms, the weig...

Embodiment 2

[0047] (1) First put 6g of samarium iron alloy powder into crucible 1, put 2.88g of ammonium carbonate solid, 4.5g of sodium hydroxide and 7g of calcium oxide into crucible 2 in order from bottom to top, and put 0.1g of metal calcium particles into crucible 2. into container 3;

[0048] (2) Then put the crucible 1 and the crucible 2 in a temperature-resistant and pressure-resistant container 4 with a volume of 200ml. ) vacuum, vacuum degree ≤ 0.05MPa;

[0049] (3) Then the crucible 2 is heated to thermally decompose the ammonium carbonate; at the same time, the crucible 1 is heated to 70° C. and kept for 60 minutes, then heated to 400° C. for nitriding, and kept for 2 hours; cooled to 350° C. for homogenization heat treatment, Homogenization heat treatment for 4h; finally lowered to room temperature to obtain Sm 2 Fe 17 N x magnetic powder.

[0050] Assuming that the increase in the mass of the magnetic powder is only related to the introduction of nitrogen atoms, the wei...

Embodiment 3

[0054] (1) First put 6g of samarium iron alloy powder into crucible 1, put 2.88g of ammonium carbonate solid, 4.5g of sodium hydroxide and 7g of calcium oxide into crucible 2 in order from bottom to top, and put 0.1g of metal calcium particles into crucible 2. into container 3;

[0055] (2) Then put the crucible 1 and the crucible 2 in a temperature-resistant and pressure-resistant container 4 with a volume of 200ml. ) vacuum, vacuum degree ≤ 0.05MPa;

[0056] (3) Then the crucible 2 is heated to thermally decompose the ammonium carbonate; at the same time, the crucible 1 is heated to 70° C. and kept for 60 minutes, then heated to 380° C. for nitriding, and kept for 6 hours; cooled to 350° C. for homogenization heat treatment, Homogenization heat treatment for 8h; finally lowered to room temperature to obtain Sm 2 Fe 17 N x magnetic powder.

[0057] Assuming that the increase in the mass of the magnetic powder is only related to the introduction of nitrogen atoms, the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com