Method for preparing 1,1-diamido-2,2-binitroethylene at normal temperature

A dinitroethylene and diamino technology, which is applied in the preparation of amino compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of difficult automatic feeding, difficult heat diffusion, safety hazards and side reactions, etc., to achieve Reduce the probability of explosion accidents and side reactions, improve heat dissipation, and simplify the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

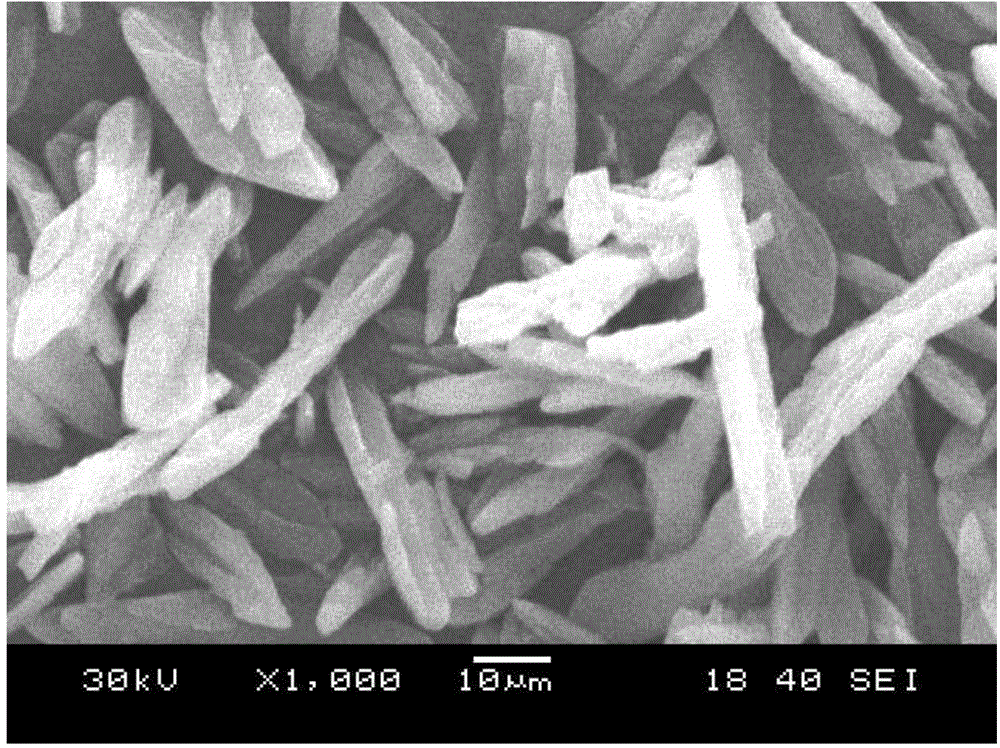

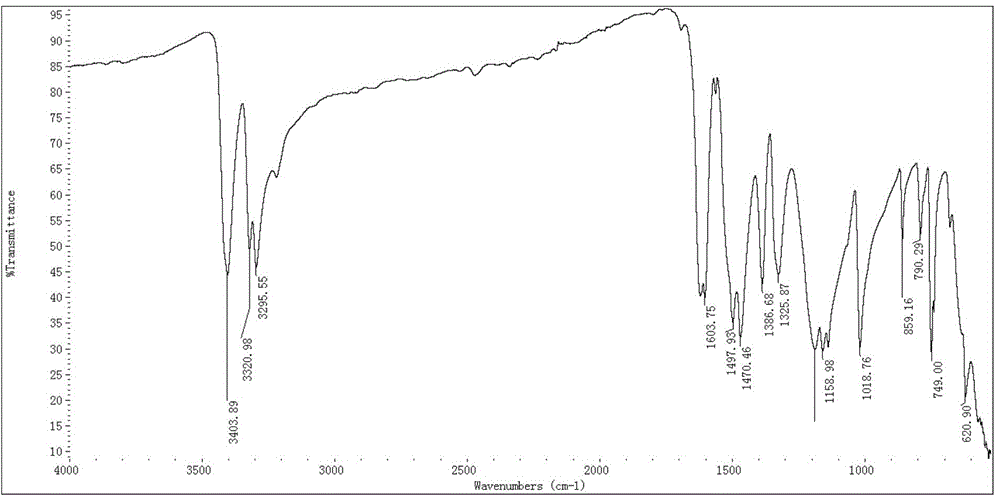

Embodiment 1

[0026] The peristaltic pump is used as the continuous conveying equipment for liquid materials, and the liquid material conveying pipeline adopts polytetrafluoroethylene pipes with an inner diameter of 2 mm. Prepare a mixed acid nitrating agent in advance according to the volume ratio of 20% oleum to fuming nitric acid at a volume ratio of 1:1, and cool to room temperature. Weigh 5.0 g of 2-methyl-4,6-dihydroxypyrimidine and add it to a 500ml three-neck flask, add dichloromethane 3 times the mass of 2-methyl-4,6-dihydroxypyrimidine, start the stirrer, The temperature of the reaction material is 22°C, which is basically the same as the room temperature. Add 30ml of mixed acid nitrating agent at a rate of 0.5ml / min, monitor the temperature of the material during the dropping process, and prevent the temperature of the material from rising by reducing the rate of addition to ensure the stability of the material. The temperature does not exceed 35°C. After adding the mixed acid n...

Embodiment 2

[0028] The peristaltic pump is used as the continuous conveying equipment for liquid materials, and the liquid material conveying pipeline adopts polytetrafluoroethylene pipes with an inner diameter of 3 mm. Pre-prepared mixed acid nitrating agent according to the volume ratio of 98% concentrated sulfuric acid and fuming nitric acid as 1:1, and cooled to room temperature. Weigh 5.0 g of 2-methyl-4,6-dihydroxypyrimidine and add it to a 500ml three-neck flask, add chloroform 10 times the mass of 2-methyl-4,6-dihydroxypyrimidine, start the stirrer, The temperature of the reaction material is 22°C, which is basically the same as the room temperature. Add 30ml of mixed acid nitrating agent at a rate of 0.5ml / min, monitor the temperature of the material during the dropping process, and prevent the temperature of the material from rising by reducing the rate of addition to ensure the stability of the material. The temperature does not exceed 35°C. After adding the mixed acid nitrati...

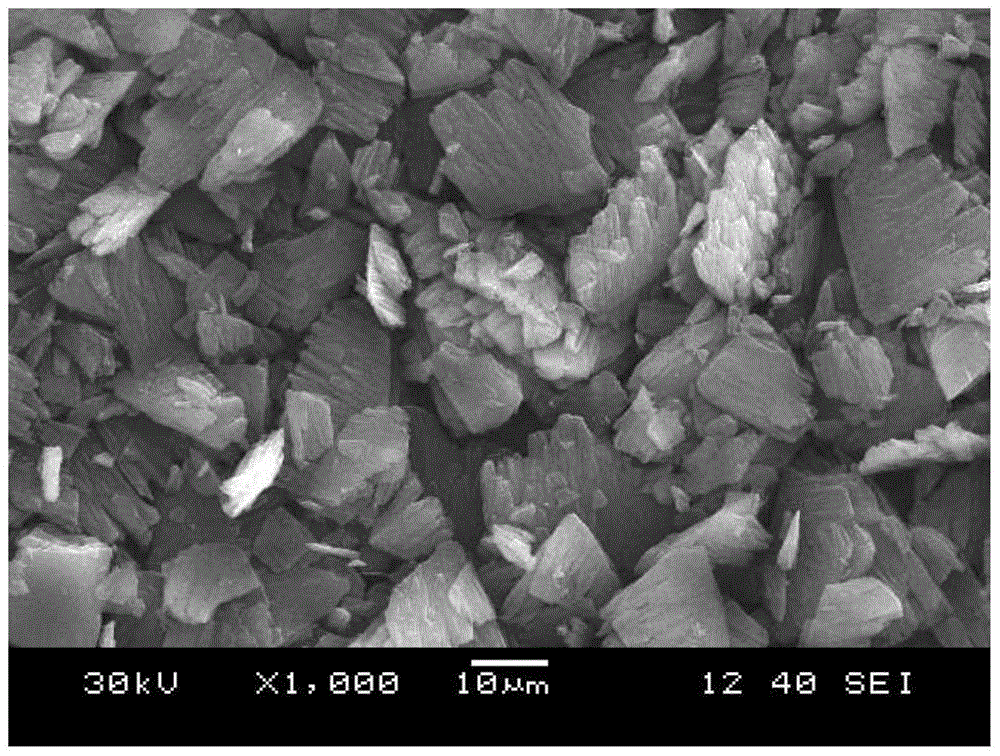

Embodiment 3

[0030]The peristaltic pump is used as the continuous conveying equipment for liquid materials, and the liquid material conveying pipeline adopts polytetrafluoroethylene pipes with an inner diameter of 3 mm. Prepare a mixed acid nitrating agent in advance according to the volume ratio of 98% concentrated sulfuric acid and fuming nitric acid at a volume ratio of 3:1, and cool to room temperature. Weigh 5.0 g of 2-methyl-4,6-dihydroxypyrimidine and add it to a 1000ml three-neck flask, add tetrachloromethane 20 times the mass of 2-methyl-4,6-dihydroxypyrimidine, start the stirrer, The temperature of the reaction material is 25°C, which is basically the same as the room temperature. Add 30ml of mixed acid nitrating agent at a rate of 0.5ml / min, monitor the temperature of the material during the dropping process, and prevent the temperature of the material from rising by reducing the rate of addition to ensure the stability of the material. The temperature does not exceed 35°C. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com