Technology and equipment for rapid growth of corundum sapphire crystal material by flame fusion method

A technology of sapphire crystal and flame melting method, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc. It can solve the problems of complex equipment structure, difficulty in smooth feeding, and easy to be affected by moisture, so as to ensure the growth quality and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

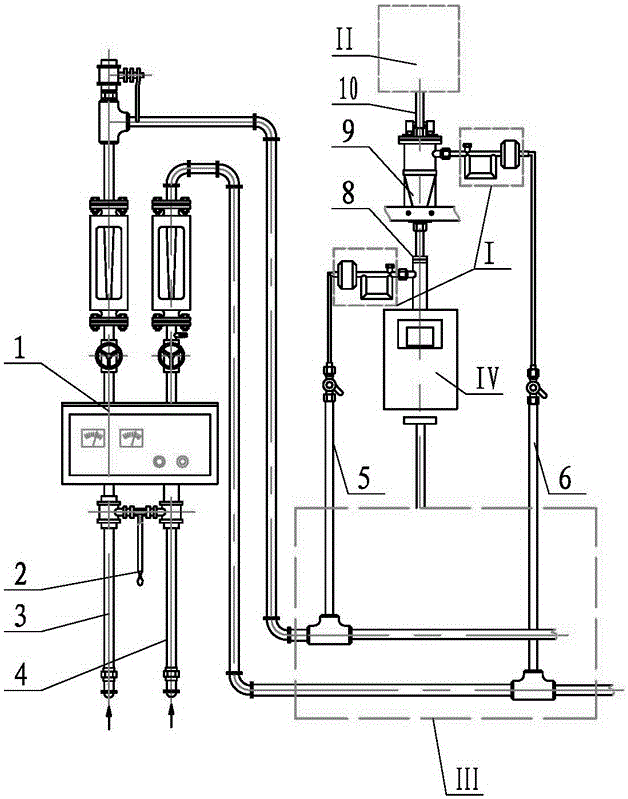

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0059] The technique for rapid growth of corundum sapphire crystal material by flame melting method is characterized in that it comprises the following steps:

[0060] (1) Fix the pre-made seed crystal on the lifting platform and straighten it;

[0061] (2) Open the hydrogen source and ignite it with an open flame in the combustion chamber;

[0062] (3) Turn on the oxygen source and adjust the flow rate to 6-8m 3 / Hour;

[0063] (4) Check the position of the flame and adjust the shape of the flame to be stable;

[0064] (5) Send the finished lifting platform into the furnace body, and adjust the seed crystal to the center of the flame, and the seed crystal is at 2 / 3 of the observation port;

[0065] (6) Melting seed: adjust the hydrogen flow rate to be: 25m / hour, increase the oxygen flow rate until the upper part of the seed cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com