Preparation method of lithium manganese phosphate nano-microsphere and product

A technology of nano-microspheres and lithium manganese phosphate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low electronic conductivity and ion conductivity, and limit the application of positive electrode materials. Achieve the effect of easy control, easy large-scale production and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

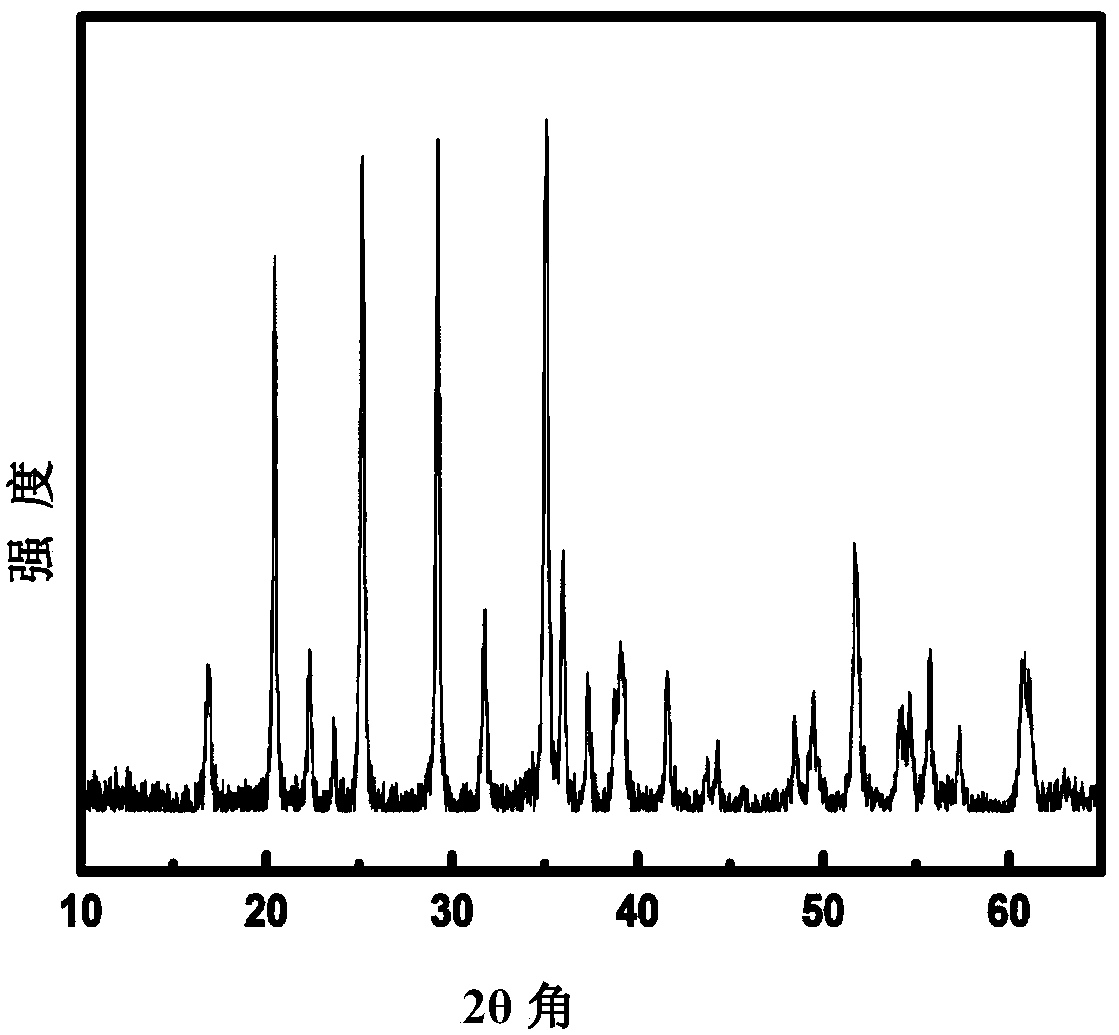

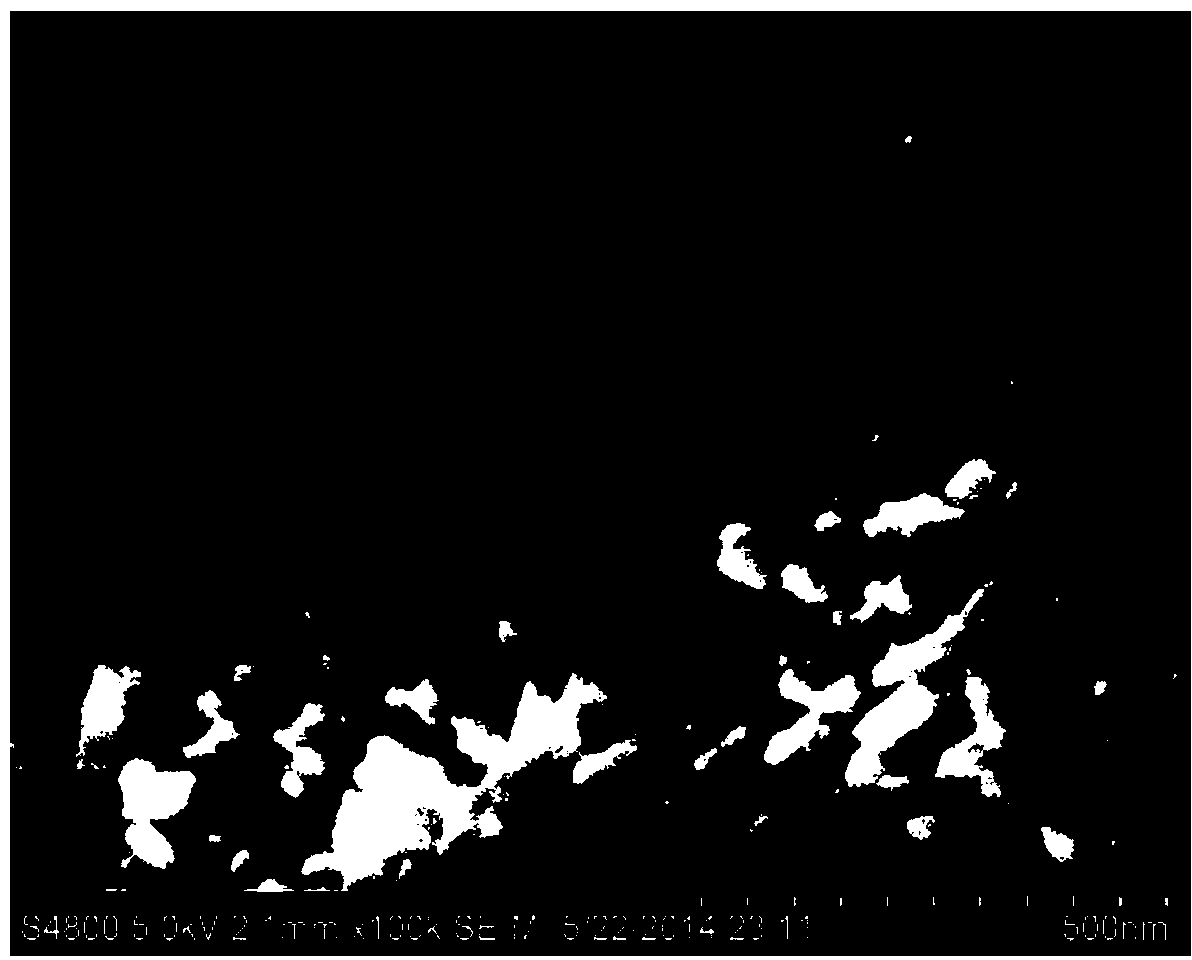

[0033] LiMnPO with a diameter of about 500 nm assembled by liquid-phase synthesis of nanorods with a diameter of about 30 nm 4 Rod assembled microspheres.

[0034] Synthesize LiMnPO according to the following process steps 4 Nanorods assemble microspheres.

[0035] 1) Measure ethylene glycol and deionized water at a volume ratio of 1:1, and mix the two to obtain a mixed solvent with a volume ratio of ethylene glycol and water of 1:1.

[0036] 2) Weigh 0.423g manganese sulfate monohydrate (MnSO 4 ·H 2 O), it is dissolved in a mixed solvent of ethylene glycol and water with a total volume of 20ml.

[0037] 3) Weigh 0.48g lithium sulfate monohydrate (Li 2 SO 4 ·H 2 O) and 0.287g ammonium dihydrogen phosphate ((NH 4 )H 2 PO 4 ), was dissolved successively in another part of ethylene glycol and water solvents with a total volume of 20ml, after stirring for 5 minutes, after adding 0.28g of potassium hydroxide (KOH), continue stirring for 30min.

[0038] 4) Slowly introduc...

Embodiment 2

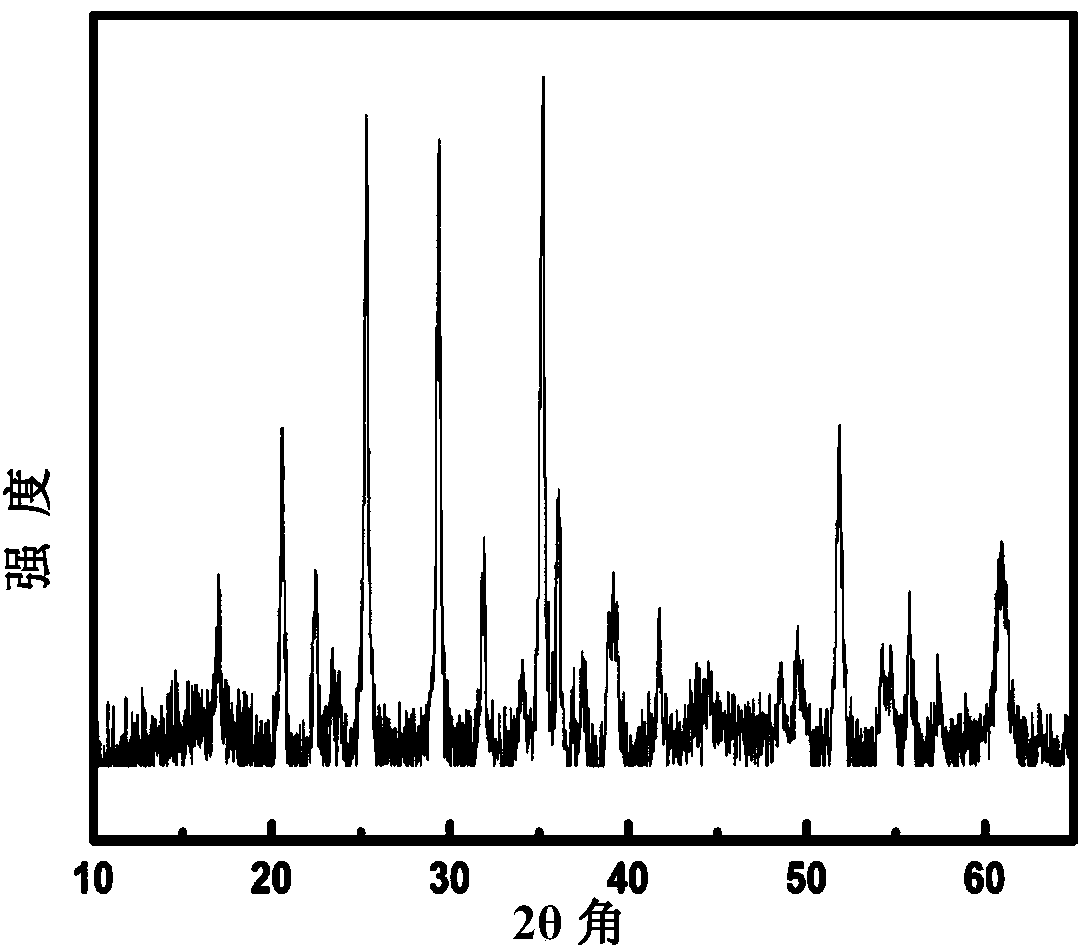

[0041] Water / Solvothermal Synthesis of LiMnPO 4 Nanorods assemble microspheres.

[0042] Concrete processing step is identical with embodiment 1, and difference is: the volume ratio of ethylene glycol and water in the mixed solvent of preparation in step 1) is 1:1.5; Step 2) takes by weighing 0.338g manganese sulfate monohydrate; Step 3) Weigh 0.32g lithium sulfate monohydrate, 0.3g ammonium dihydrogen phosphate and 0.28g potassium hydroxide; in step 5), the heat treatment temperature is 160°C, and the temperature is kept for 24 hours.

Embodiment 3

[0044] Water / Solvothermal Synthesis of LiMnPO 4 Nanorods assemble microspheres.

[0045] Concrete processing step is identical with embodiment 1, and difference is: the volume ratio of ethylene glycol and water in the mixed solvent of preparation in step 1) is 1:2; Step 2) takes by weighing 0.563g manganese sulfate monohydrate; Step 3) 0.64g of lithium sulfate monohydrate, 0.383g of ammonium dihydrogen phosphate and 0.35g of potassium hydroxide were weighed; in step 5), the heat treatment temperature was 240°C and the temperature was kept for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com