Intelligent temperature control efficient heat preservation cup

An intelligent temperature control and thermos cup technology, applied in the field of thermos cups, can solve the problems of expensive phase change materials, low thermal conductivity, difficult to apply in large quantities, etc., and achieve easy manufacture and use, excellent thermal insulation performance, and good practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

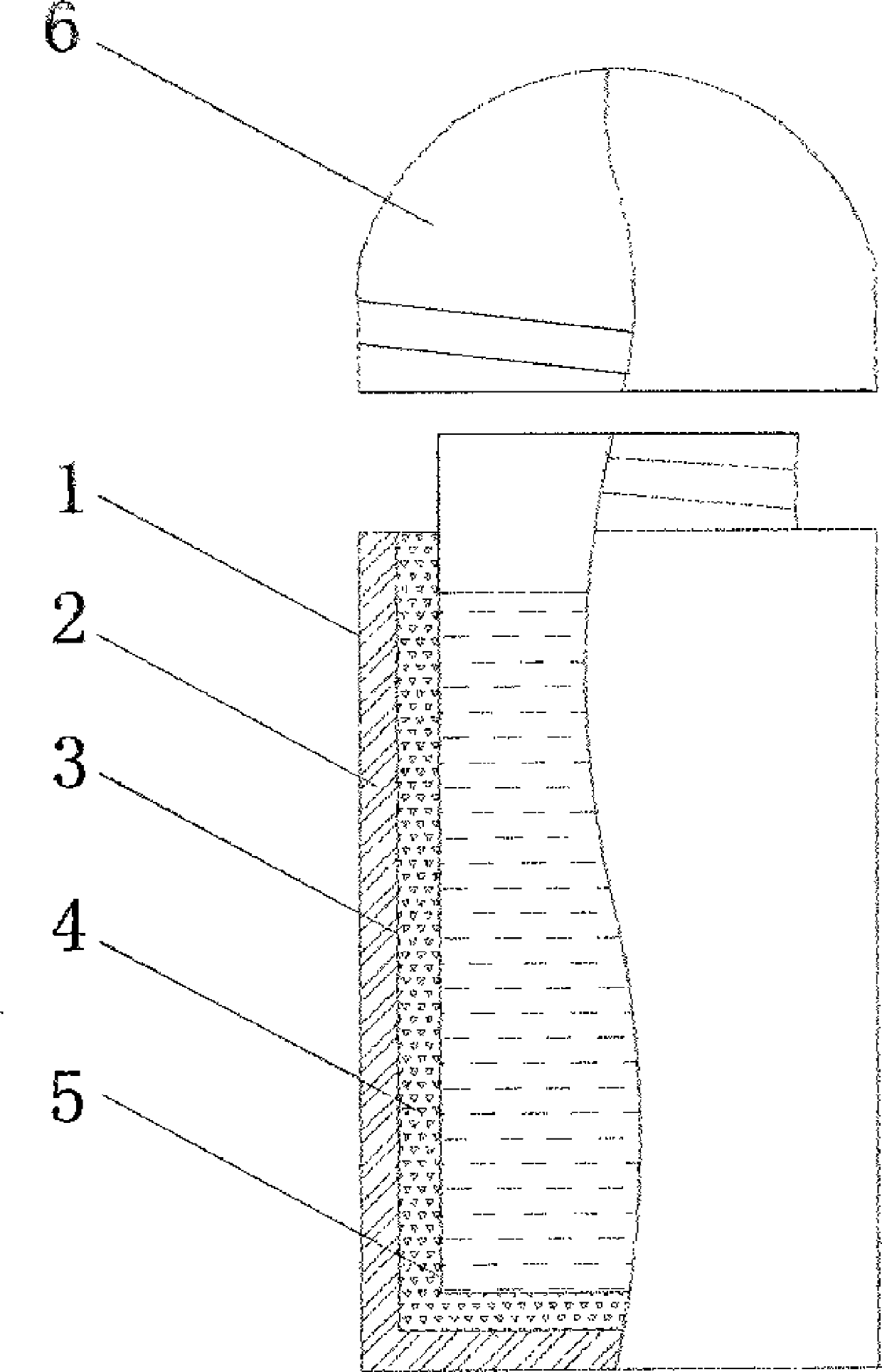

Image

Examples

Embodiment 1

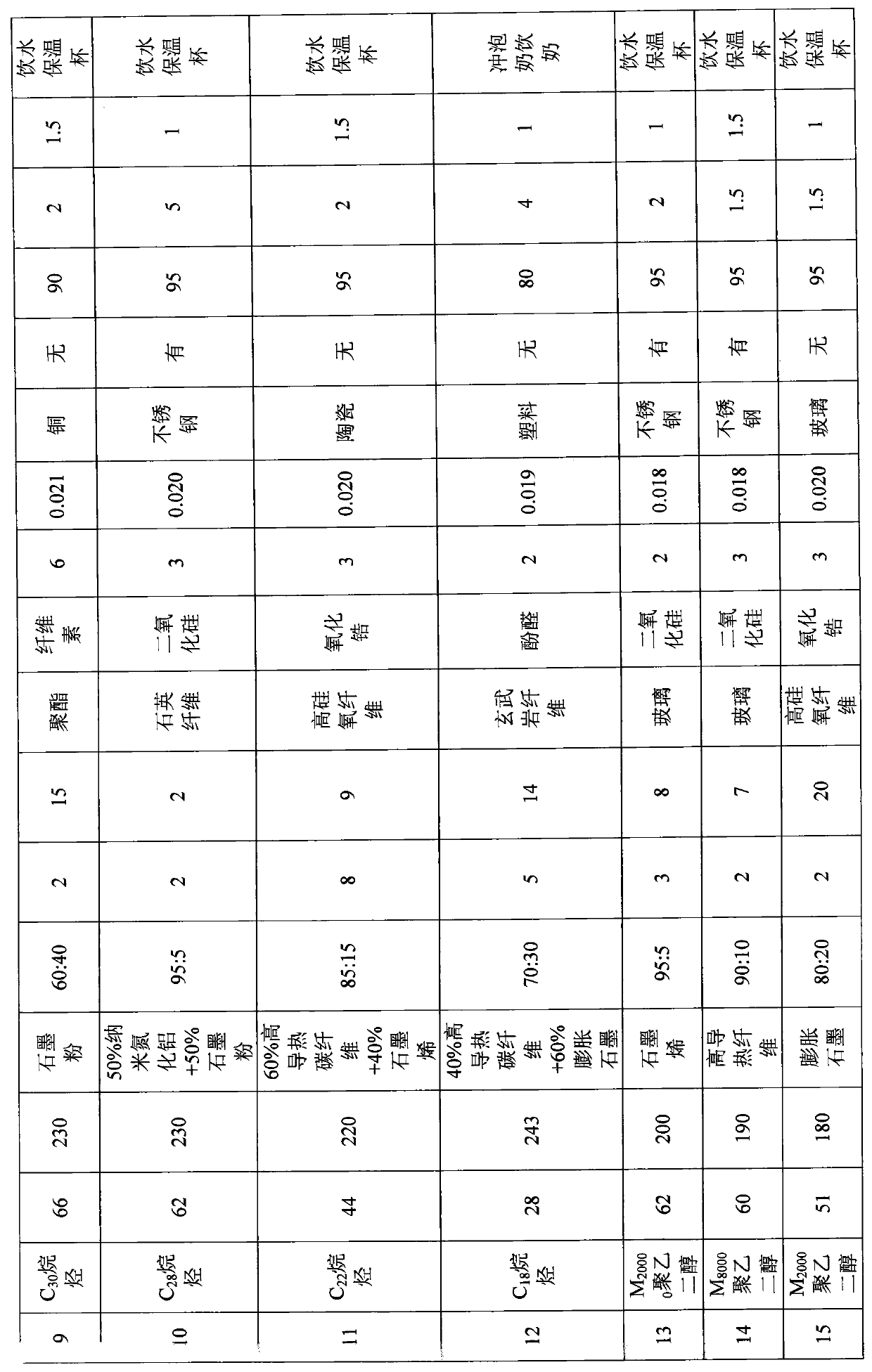

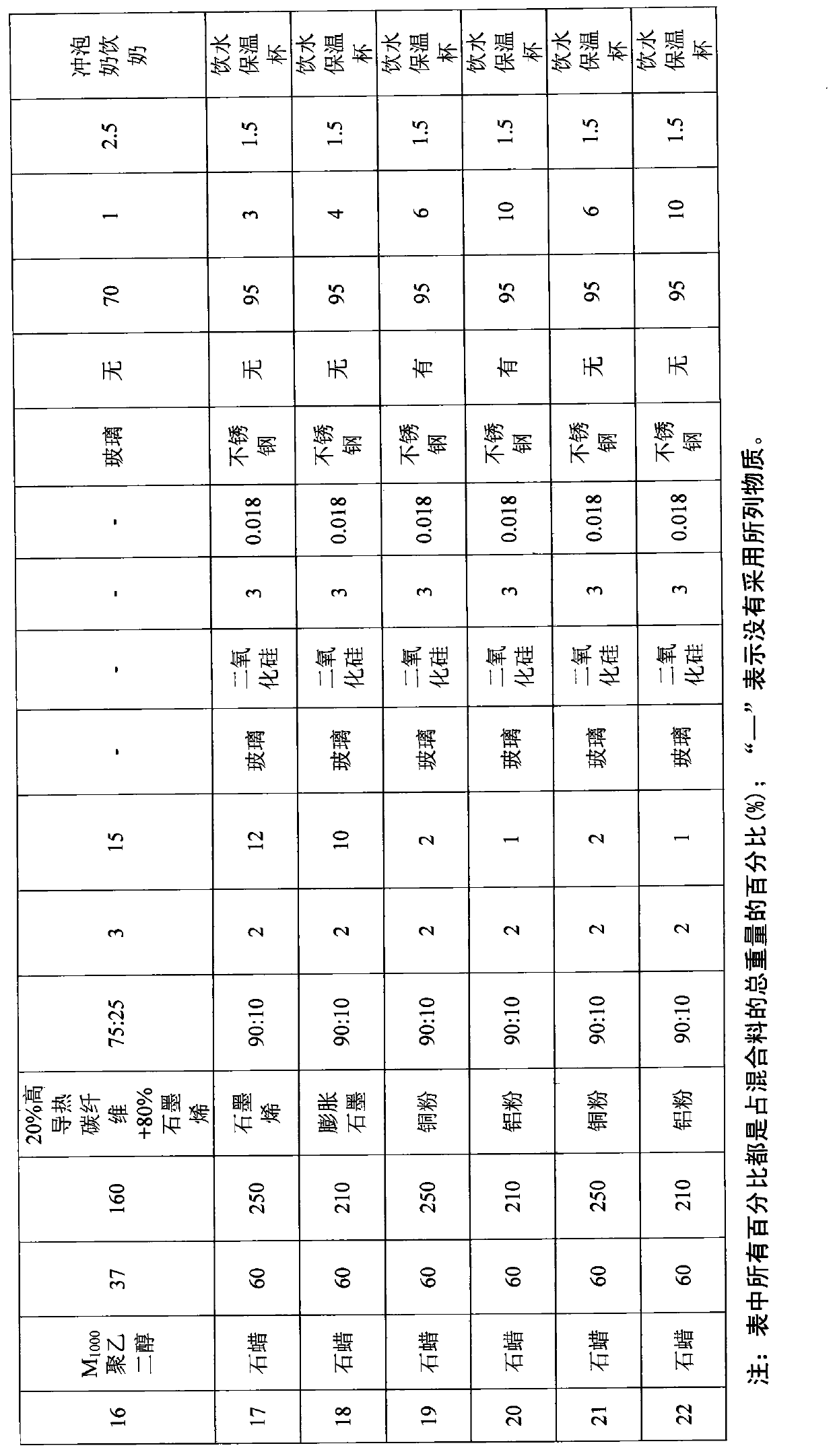

[0057] Manufacture an intelligent temperature-controlled high-efficiency thermos cup, in which stainless steel is used as the outer cylinder wall and the inner cylinder wall, the inner cylinder wall is close to the 2mm thermal conductivity phase change layer, and the thermal conductivity phase change layer is close to the 2mm glass fiber composite silica air condensation The heat insulation layer is made of glue, and the outside of the airgel heat insulation layer is the wall of the outer cylinder. The thermally conductive phase change layer is composed of paraffin wax with a melting point of 60°C and expanded graphite at a mass percentage of 90% and 10%, the thermal conductivity is 10W / m K, and the phase transition temperature of paraffin wax with a melting point of 60°C is 60°C. The latent heat of phase change is 210kJ / kg.

[0058] Pour hot water above 95°C into the intelligent temperature-controlled high-efficiency thermos cup. After 1 minute, the hot water in the cup will ...

Embodiment 2

[0060] Manufacture an intelligent temperature-controlled high-efficiency thermos cup, in which stainless steel is used as the outer cylinder wall and the inner cylinder wall, the inner cylinder wall is close to the 2mm thermal conductivity phase change layer, and the thermal conductivity phase change layer is close to the 3mm glass fiber composite silica gas The gel heat insulation layer is an outer cylinder wall outside the fiber composite airgel heat insulation layer. The thermally conductive phase-change layer is composed of paraffin wax with a melting point of 80°C and graphene at a mass percentage of 95% and 5%, and its thermal conductivity is 5W / m K. ℃, the latent heat of phase change is 250kJ / kg.

[0061] Pour hot water above 95°C into the intelligent temperature-controlled high-efficiency thermos cup. After 1 minute, the hot water in the cup drops to about 80°C, reaching the temperature for making tea (green tea). When the lid is tightly closed, the hot water in the c...

Embodiment 3

[0063] Manufacture an intelligent temperature-controlled high-efficiency thermos cup, in which glass is used as the outer cylinder wall and the inner cylinder wall, and the inner cylinder wall is closely attached to the 2mm heat-conducting phase change layer. The thermally conductive phase change layer is composed of paraffin wax with a melting point of 40°C and expanded graphite at a mass percentage of 80% and 20%, and its thermal conductivity is 20W / m·K. ℃, the latent heat of phase change is 220kJ / kg.

[0064] Pour hot water at about 70°C into the intelligent temperature-controlled high-efficiency thermos cup. After 2 minutes, the hot water in the cup drops to about 40°C, reaching the temperature for brewing milk powder. With the lid tightly closed, the hot water in the cup is maintained at 40-35°C for 0.5 hours, and then the temperature in the cup drops slowly. The intelligent temperature-controlled high-efficiency thermos cup described in this embodiment can be used as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com