Poly dopamine-modified reduced graphene oxide and preparation method and application thereof

A polydopamine and graphene technology, applied in the field of new materials, can solve problems such as unfavorable industrial production, environmental hazards, etc., and achieve the effects of good application value, low reduction temperature, and improved photothermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

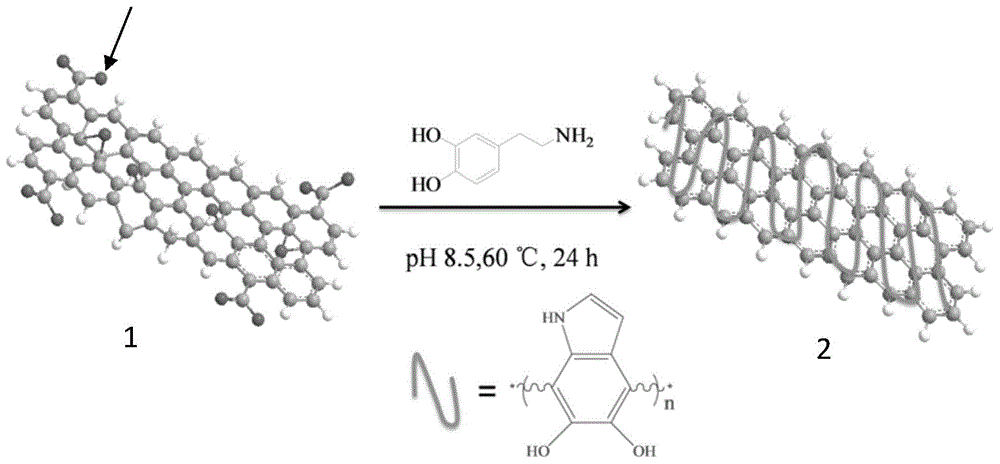

[0037] A preparation method of polydopamine-modified reduced graphene oxide, comprising the steps of:

[0038] (1) First weigh 10 mg of graphene oxide (GO) and add it into a round-bottomed flask filled with 20 mL of 10 mM Tris-Cl solution with a pH of 8.5, and ultrasonically place the round-bottomed flask in an ice-water bath for 10 minutes to make graphite oxide Alkenes are completely dissolved in Tris-Cl solution;

[0039] (2) Add 5 mg of dopamine hydrochloride (DA) to the above-mentioned round-bottomed flask, then stir and ultrasonicate the round-bottomed flask in an ice-water bath for 10 minutes to activate dopamine hydrochloride to obtain a yellow-brown reaction mixed solution;

[0040] (3) Place the above reaction mixture solution under the condition of 60° C. and vigorously stir for 24 hours;

[0041] (4) Remove the free dopamine hydrochloride by centrifuging the above reaction mixture solution (rotating speed is set to 10,000rpm / min, each wash is 20min, wash 8 times) ...

Embodiment 2

[0048] A preparation method of polydopamine-modified reduced graphene oxide, comprising the steps of:

[0049] (1) First take by weighing 10mg graphene oxide and add the concentration that 20mLpH is 9.0 is that 10mM Tris-Cl solution is housed in the round bottom flask of 10mM Tris-Cl solution at first, and this round bottom flask is ultrasonicated in ice-water bath for 10 minutes, graphene oxide is completely dissolved in In Tris-Cl solution;

[0050] (2) Add 2.5 mg of dopamine hydrochloride to the above-mentioned round-bottomed flask, then stir and ultrasonicate the round-bottomed flask in an ice-water bath for 10 minutes to activate dopamine hydrochloride to obtain a tan reaction mixed solution;

[0051] (3) Place the above reaction mixture solution under the condition of 65° C. and vigorously stir for 12 hours;

[0052] (4) Remove free dopamine hydrochloride by centrifuging the above reaction mixture solution (rotating speed is set at 10,000rpm / min, each wash is 20min, 8 t...

Embodiment 3

[0054] A preparation method of polydopamine-modified reduced graphene oxide, comprising the steps of:

[0055] (1) First take by weighing 10mg graphene oxide and add that 20mL pH is that the concentration of 8.5 is in the round-bottomed flask of 10mM Tris-Cl solution, and this round-bottomed flask is sonicated in ice-water bath for 10 minutes, graphene oxide is completely dissolved in In Tris-Cl solution;

[0056] (2) Add 10 mg of dopamine hydrochloride to the above-mentioned round-bottomed flask, then stir and ultrasonicate the round-bottomed flask in an ice-water bath for 10 minutes to activate dopamine hydrochloride to obtain a tan reaction mixed solution;

[0057] (3) Place the above reaction mixture solution under the condition of 55° C. and vigorously stir for 24 hours;

[0058] (4) Remove free dopamine hydrochloride by centrifuging the above reaction mixture solution (rotating speed is set at 10,000rpm / min, each wash is 20min, 8 times in total) to obtain polydopamine-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com