Square (circular) hole sleeve for external locking mechanism of point machine and powder metallurgy manufacture method thereof

A technology of powder metallurgy and manufacturing method, which is applied in the field of square (round) hole sleeves for external locking mechanisms of switch machines and the field of powder metallurgy manufacturing thereof, which can solve the problem of poor shock resistance, corrosion resistance, high and low temperature resistance, and hole sleeve waste products. It can reduce the consumption of resources and energy, increase the frictional contact area, and reduce the wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

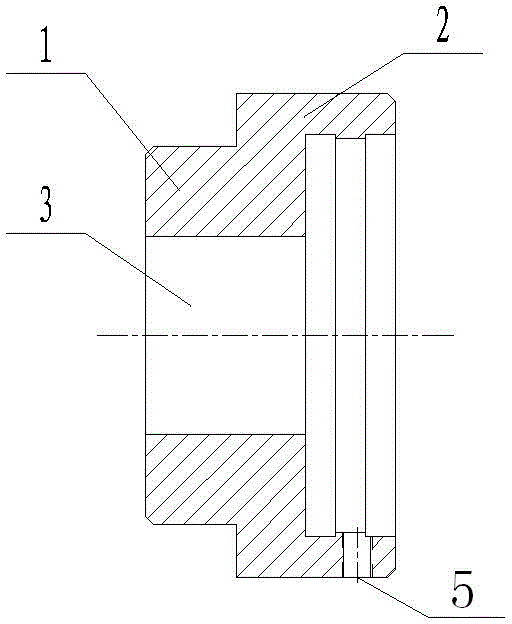

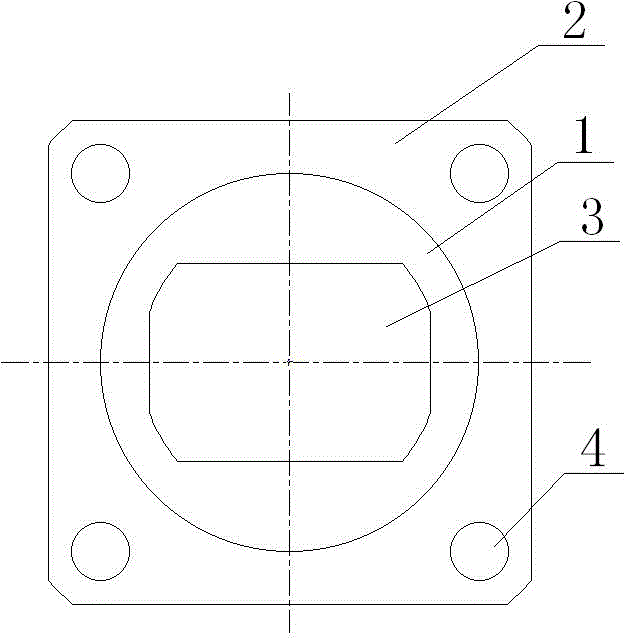

[0047] Such as figure 1 with figure 2 As shown, the circular socket for the external locking mechanism of the switch machine includes the socket body 1 and the socket seat 2, the outer contour of the socket body 1 is cylindrical, and the external contour of the socket seat 2 is cuboid. And the cross-section of the cuboid shape is square and the thickness is less than the square side length; the hole sleeve body 1 is arranged on the square end face of the hole sleeve seat 2, and the hole sleeve body 1 and the hole sleeve seat 2 are integrally formed; The main body 1 is provided with a through hole 3 in the axial direction, and a circular cavity is opened in the middle of the hole sleeve 2, and the diameter of the circular cavity is larger than the diameter of the through hole 3 and the two are coaxial; the through hole 3 The cross-section is rectangular; the side of the socket seat 2 is provided with a lubricating oil hole 5 communicating with the circular cavity, the lubric...

Embodiment 2

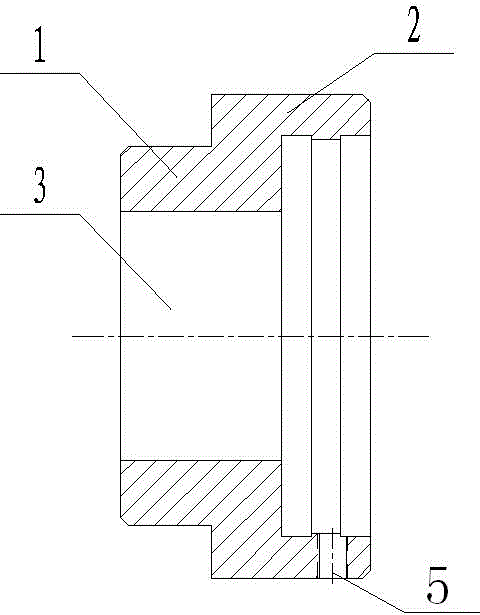

[0050] Such as image 3 with Figure 4As shown, the square socket for the external locking mechanism of the switch machine includes a socket body 1 and a socket seat 2. The outer contour of the hole socket body 1 is cylindrical, and the external contour of the hole socket seat 2 is cuboid. And the cross-section of the cuboid shape is square and the thickness is less than the square side length; the hole sleeve body 1 is arranged on the square end face of the hole sleeve seat 2, and the hole sleeve body 1 and the hole sleeve seat 2 are integrally formed; The main body 1 is provided with a through hole 3 in the axial direction, and a circular cavity is opened in the middle of the hole sleeve 2, and the diameter of the circular cavity is larger than the diameter of the through hole 3 and the two are coaxial; the through hole 3 The cross section is a rectangle with four-corner circular arc transition; the side of the socket seat 2 is provided with a lubricating oil hole 5 communi...

Embodiment 3

[0053] The preparation method of the round hole sleeve described in embodiment 1 includes batching, pressing, sintering, vacuum oil immersion, fine shaping and machining, specifically made according to the following steps:

[0054] 1) Raw material and weight percentage ratio

[0055] 200-mesh copper powder 3%, 325-mesh graphite powder 0.7%, 325-mesh ferromolybdenum powder 0.7%, 400-mesh sulfur powder 0.4%, and the balance is 80-mesh iron powder;

[0056] 2) Pressed blank

[0057] Mix the raw materials in step 1) and put them into the mold cavity designed according to the structure of the square hole sleeve or the round hole sleeve, and press the blank under a pressure of 560Mpa;

[0058] 3) Sintering

[0059] Sinter the pressed product in an atmosphere of decomposed ammonia with a dew point of 40°C, the sintering temperature is 1120±10°C, and the time is 120min;

[0060] 4) Vacuum immersion oil

[0061] The vacuum degree is 0.1MPa, the temperature is 40°C, and the oil imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com