A gasification quenching process of insoluble sulfur

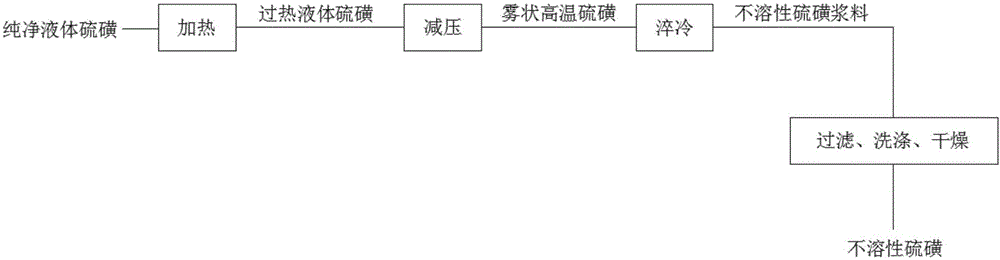

A sulfur and quenching technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of wide particle size distribution of semi-finished insoluble sulfur products, no improvement in the contact mode of quenching medium, and difficulty in controlling the thermal stability and dispersion of finished products. , to achieve the effect that is conducive to quenching absorption, low production cost, and sufficient and detailed quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add the prepared 20 ℃, 100L carbon disulfide quenching liquid into a vertical reaction tank with a jacket (heat exchange device) with a volume of 300 L, and use a circulation pump to extract the carbon disulfide quenching liquid from the bottom of the vertical reaction tank and transport it to The spraying device in the upper part of the reaction tank is used for spraying, and a liquid curtain of circulating spray is formed in the vertical reaction tank. The liquid curtain is in the shape of a shower spray. The flow rate of the circulating pump is controlled at 1500L / h, and the pressure in the reaction tank is maintained at 0.01 MPa.

[0028] The liquid sulfur heated to 550°C-580°C in the heating device with an internal pressure of 0.6Mpa is passed into the upper liquid curtain of the vertical reaction tank at a rate of 1.05kg / min, and the circulating water volume in the jacket of the vertical reaction tank is controlled. Keep the temperature of the material in the tank...

Embodiment 2

[0032] The gasification and quenching process of insoluble sulfur described in this embodiment is as described in Example 1, the difference is that the liquid sulfur is heated to 600°C-610°C in a heating device with an internal pressure of 1Mpa and At a speed of 1.05kg / min, it is passed into the liquid curtain at the upper part of the vertical reaction tank whose pressure is maintained at 0.1Mpa and the temperature is 60°C; the temperature of the solid-liquid two-phase material obtained at last is 70°C, and the mass concentration of the solid phase is 35%. , the solid-liquid two-phase material in the lower part of the vertical reaction tank is sucked and washed with 100kg carbon disulfide, and then sent to a vacuum drying oven for sufficient drying to obtain 25.8kg insoluble sulfur powder with a yield of 51.6%. The detection indexes are as follows: thermal stability at 120° C. for 15 minutes is 56.1%, average particle size is 34 microns, and purity is 96.3%.

Embodiment 3

[0034] The gasification and quenching process of insoluble sulfur described in this embodiment is as described in Example 1, the difference is that the liquid sulfur is heated to 620°C-630°C in a heating device with an internal pressure of 1Mpa and Pass into the liquid curtain on the upper part of the vertical reaction tank by the speed of 0.9kg / min; The solid-liquid two-phase material was suction-filtered and washed with 100 kg of carbon disulfide, then sent to a vacuum drying oven for sufficient drying to obtain 26.3 kg of insoluble sulfur powder with a yield of 52.6%. The detection indexes are as follows: thermal stability at 120° C. for 15 minutes is 57.3%, average particle diameter is 29 microns, and purity is 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com