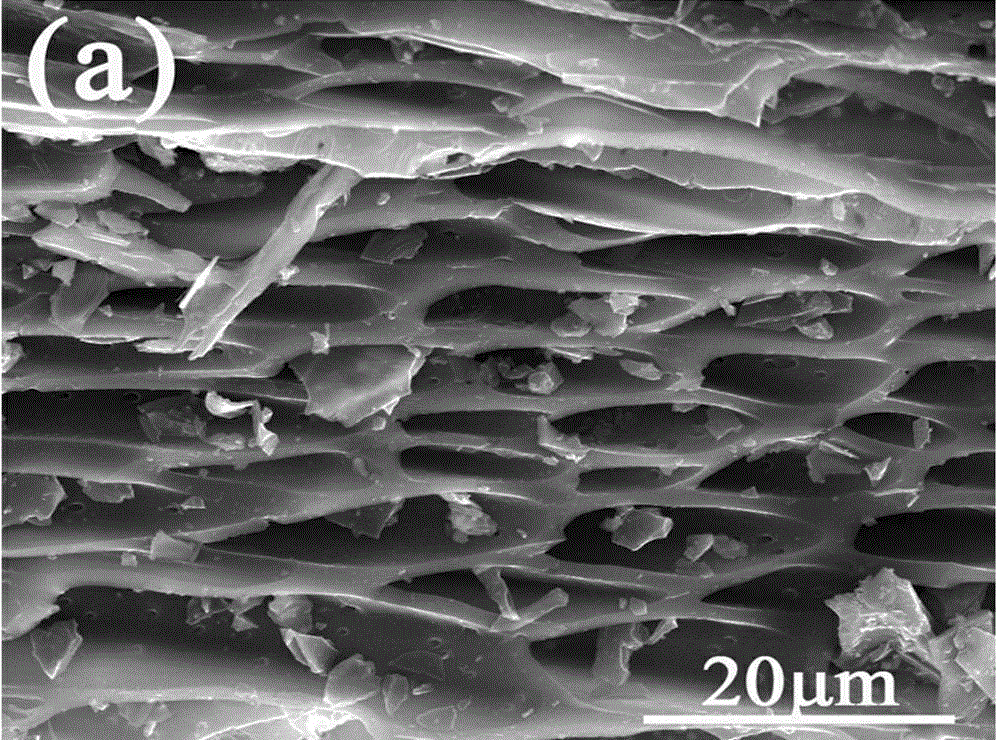

Method for preparing activated carbon with high specific surface area by using conyza canadensis

A high specific surface area, activated carbon technology, applied in the field of high specific surface area activated carbon, can solve the problems of uneven performance of carbon materials, limited geographical or output, and restrictions on industrialization development, and achieve low price, easy industrial production, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

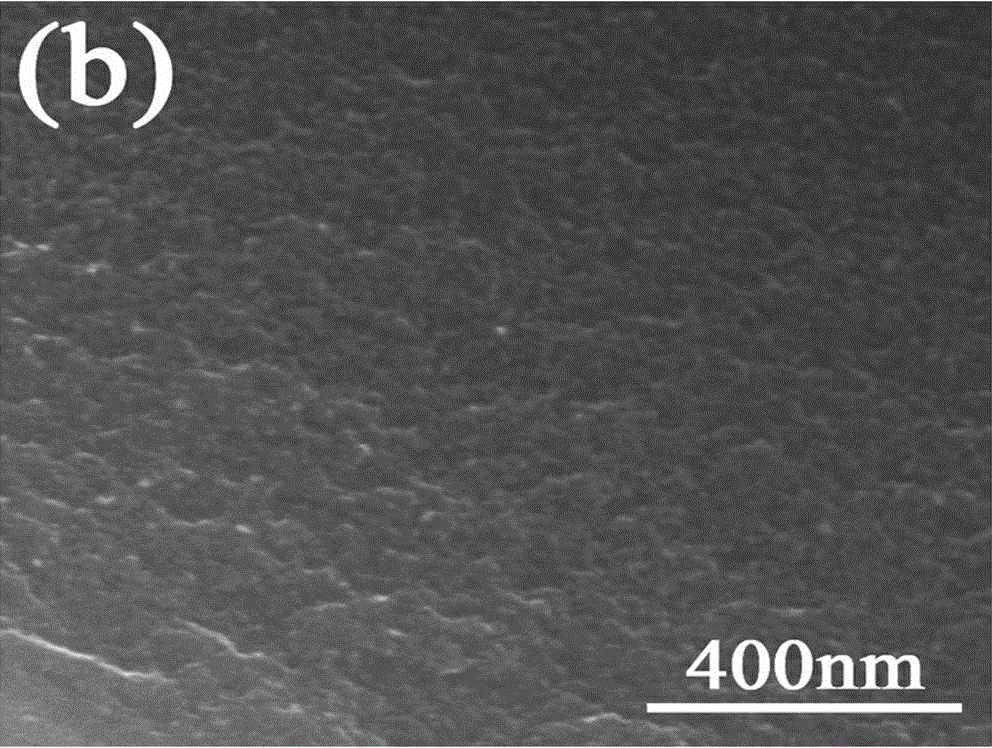

[0035] Figure 1b It is the field emission scanning diagram of the activated carbon material at 700°C in the present invention. In the figure, 2g of chrysanthemum is carbonized in a high-temperature carbonization furnace using an inert gas protection method. The treatment temperature is 1050°C and the treatment time is 15 hours to obtain charcoal material, grind it into powder, and pass through a 200-mesh sieve; take 1g of the powder, mix it with KOH at a mass ratio of 1:5, dissolve it in deionized water and absolute ethanol, stir for 24 h, and put it in a vacuum In a drying oven, dry at 120°C for 10 h, and activate the pre-activated carbon material sample at 700°C. The whole activation and cooling process is carried out under the protection of high-purity inert gas. The obtained activated carbon material was put into 2 M HCl solution and stirred for 10 h. After fully reacting, it was washed with hot water at 90-100°C and filtered until it was washed to neutrality (pH≈6-7). P...

Embodiment 2

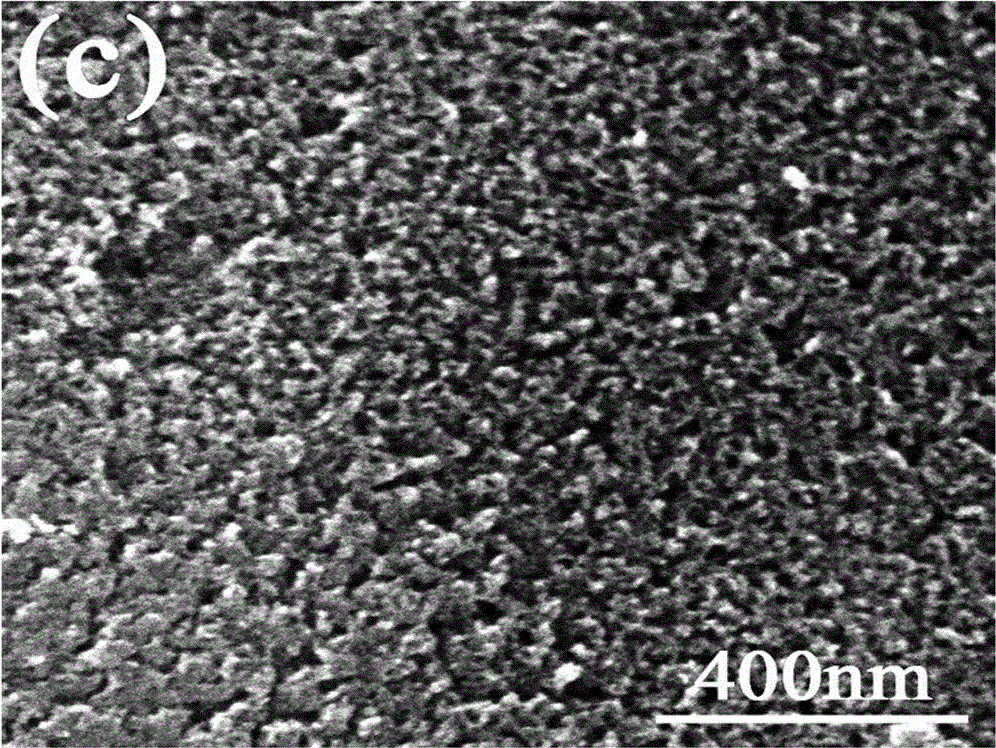

[0037] Figure 1c It is the field emission scanning diagram of the activated carbon material at 800°C in the present invention. In the figure, 2g of basilica is carbonized in a high-temperature carbonization furnace using an inert gas protection method. The treatment temperature is 1050°C and the treatment time is 15 hours to obtain charcoal material, grind it into powder, and pass through a 200-mesh sieve; take 1g of the powder, mix it with KOH at a mass ratio of 1:5, dissolve it in deionized water and absolute ethanol, stir for 24 h, and put it in a vacuum In a drying oven, dry at 120°C for 10 h, and activate the pre-activated carbon material sample at 800°C. The whole activation and cooling process is carried out under the protection of high-purity inert gas. The obtained activated carbon material was put into 2 M HCl solution and stirred for 10 h. After fully reacting, it was washed with hot water at 90-100°C and filtered until it was washed to neutrality (pH≈6-7). Put th...

Embodiment 3

[0039] Figure 1d It is the field emission scanning diagram of the activated carbon material at 900°C in the present invention. In the figure, 2g of chrysalis is carbonized in a high-temperature carbonization furnace using an inert gas protection method. The treatment temperature is 1050°C and the treatment time is 15 hours to obtain charcoal material, grind it into powder, and pass through a 200-mesh sieve; take 1g of the powder, mix it with KOH at a mass ratio of 1:5, dissolve it in deionized water and absolute ethanol, stir for 24 h, and put it in a vacuum In a drying oven, dry at 120°C for 10 h, and activate the pre-activated carbon material sample at 900°C. The whole activation and cooling process is carried out under the protection of high-purity inert gas. The obtained activated carbon material was put into 2 M HCl solution and stirred for 10 h. After fully reacting, it was washed with hot water at 90-100°C and filtered until it was washed to neutrality (pH≈6-7). Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com