Flame-retardant cement-based cushion self-leveling

A flame-retardant, self-leveling technology, applied in the field of building materials, to achieve good waterproof and flame-retardant properties, simple production, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

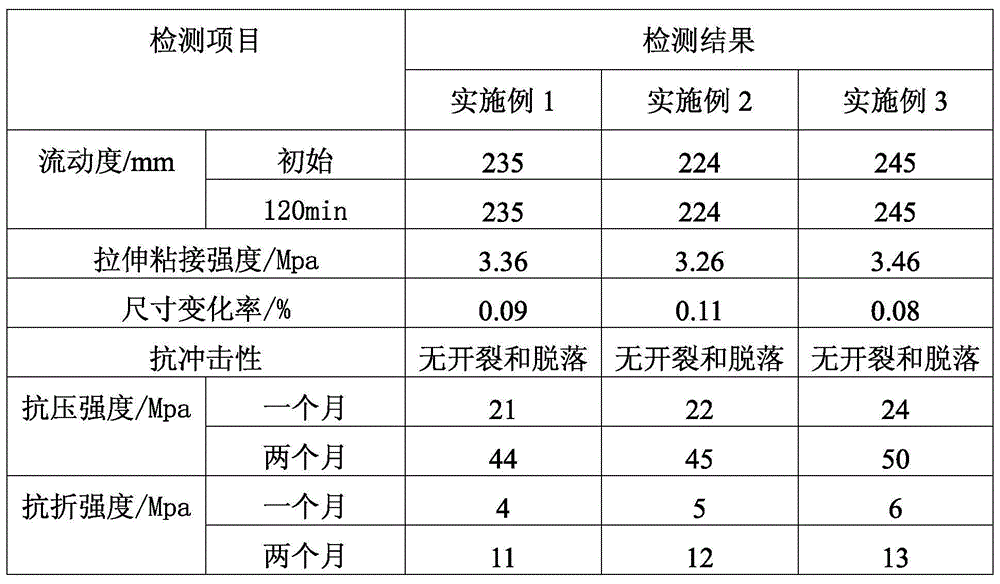

Examples

Embodiment 1

[0034] The flame-retardant cement-based cushion provided by the present invention is self-leveling, and the weight percentage of each material component is as follows:

[0035] Cement 18%

[0036] Aggregate 10%

[0037] Fine material 5%

[0038] Superplasticizer 0.15%

[0039] Defoamer 0.15%

[0040] Stabilizer 0.05%

[0041] Latex powder 1.5%

[0042] Retarder 0.2%

[0043] Coagulant 0.1%

[0044] Acrylic styrene emulsion 15%

[0045] Preservative 0.18%

[0046] Dispersant 0.15%

[0047] Quartz sand 12%

[0049] Water reducing agent 0.1%

[0050] Flame retardant 0.1%, the rest is water.

Embodiment 2

[0052] The flame-retardant cement-based cushion provided by the present invention is self-leveling, and the weight percentage of each material component is as follows:

[0053] Cement 20%

[0054] Aggregate 15%

[0055] Fine material 6%

[0056] Superplasticizer 0.16%

[0057] Antifoaming agent 0.18%

[0058] Stabilizer 0.15%

[0059] Latex powder 1.6%

[0060] Retarder 0.24%

[0061] Accelerator 0.13%

[0062] Acrylic styrene emulsion 20%

[0063] Preservative 0.2%

[0064] Dispersant 0.16%

[0065] Quartz sand 18%

[0067] Water reducing agent 0.15%

[0068] The flame retardant is 0.18%, and the rest is water.

Embodiment 3

[0070] The flame-retardant cement-based cushion provided by the present invention is self-leveling, and the weight percentage of each material component is as follows:

[0071] Cement 25%

[0072] Aggregate 20%

[0073] Fine material 10%

[0074] Superplasticizer 0.2%

[0075] Antifoaming agent 0.3%

[0076] Stabilizer 0.2%

[0077] Latex powder 2%

[0078] Retarder 0.3%

[0079] Accelerator 0.2%

[0080] Acrylic styrene emulsion 25%

[0081] Preservative 0.25%

[0082] Dispersant 0.2%

[0083] Quartz sand 22%

[0085] Water reducing agent 0.2%

[0086] The flame retardant is 0.25%, the rest is water.

[0087] This product first puts the components in a non-gravity mixing mixer for mixing, mixing for 120 minutes to make them evenly mixed, and then standing for 300 minutes, then passing through a 200-mesh sieve, and storing in a sealed package.

[0088] When using, put the prepared product slurry in a non-gravity mixing mixer, and continuously add water to stir until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com