Preparation method of metakaolin-based magnesium oxide type rapid repair material

A metakaolin-based magnesia technology, which is applied in the field of preparation of metakaolin-based magnesia-type rapid repair materials, can solve the problems of slow strength growth, slow setting and hardening process, and low early strength, and achieve high early strength and initial setting. Shorter time and better work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

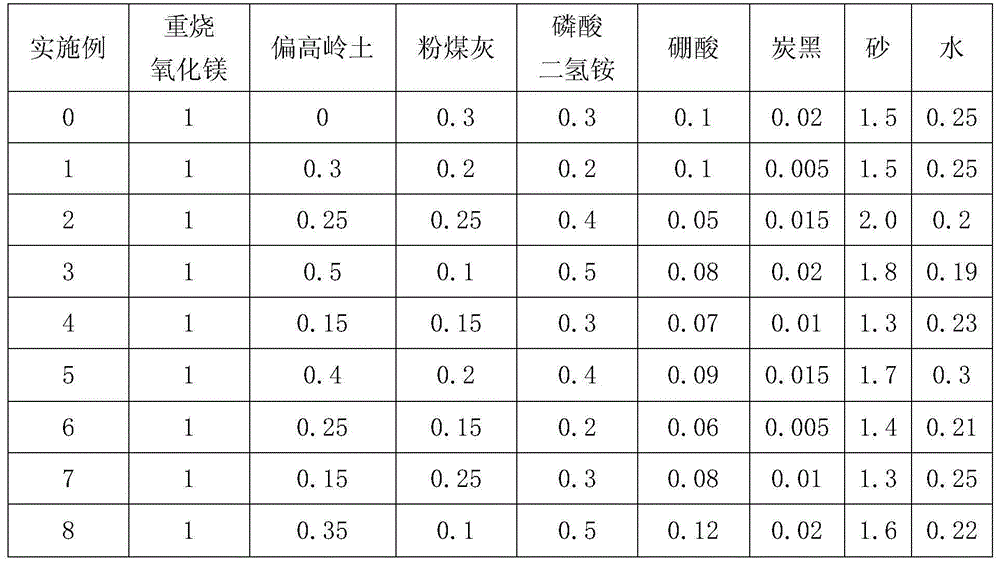

[0031] Embodiment 1-8, the weight ratio of each raw material is shown in Table 1.

[0032] Table 1

[0033]

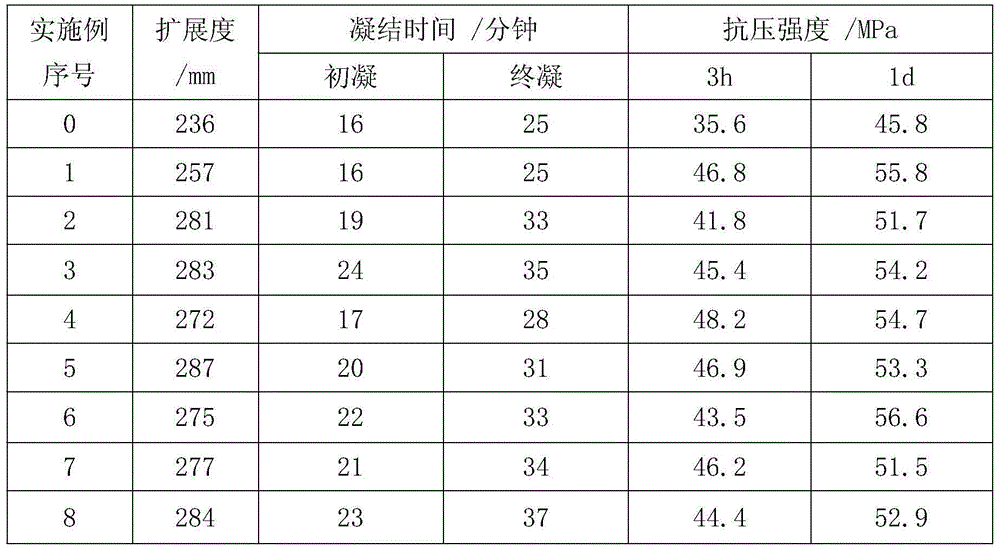

[0034] Test its expansion degree and coagulation time in advance, and then use a 40mm×40mm×160mm triple test mold to form the sample according to JGJ55-2000. After standing at room temperature for 1 hour, remove the mold, and cure it at room temperature for 3 hours (3h) and 1 day. (1d) After that, test its strength on DKZ-5000 electric cement bending machine and WE-5 hydraulic universal testing machine.

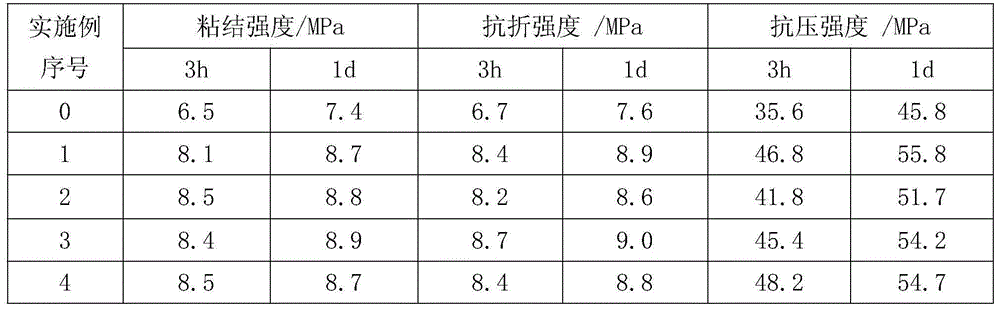

[0035] The interface bonding strength between the quick repair material and the old concrete was measured by the indirect method of flexural strength. Firstly, a 40mm×40mm×160mm cement mortar test block (JGJ55-2000, standard mortar strength test) was prepared, and maintained in water for 28 days. The cement mortar test block is cut horizontally from the middle, and half of it is placed at the bottom of the 40mm×40mm×160mm mold with the section facing up, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com