Pretreatment method of aluminum nitride substrate for copper cladding

An aluminum nitride substrate and pretreatment technology, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of low peel strength, poor temperature cycle resistance, and high porosity, and promote uniformity effect of growth, improved wetting, reduced process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

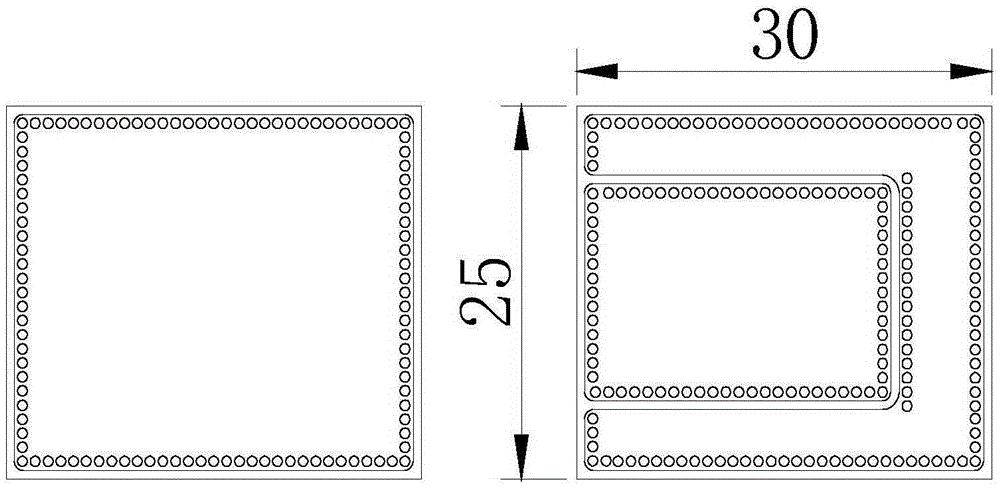

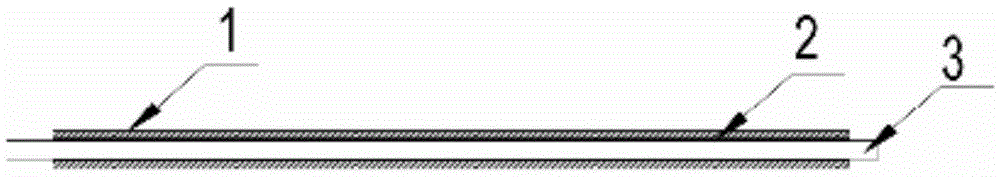

[0033] Example 1, such as figure 2 The aluminum nitride DBC structure is shown, the ceramic thickness is 0.635mm, and the length and width are 76.2mm.

[0034] Put the self-made aluminum nitride substrate into the degreasing solution and ultrasonically clean it for 10 minutes, and the surface is clean and free of oil.

[0035] The aluminum nitride substrate was placed in a NaOH solution with a concentration of 0.1mol / L for activation, and ultrasonic treatment was used for 5 minutes, ultrasonic power was 60%, and water temperature was 60°C.

[0036] A transition layer was prepared on the surface of the activated aluminum nitride substrate by dipping method, the molar content of manganese nitrate in the transition layer was 0.01mol / L, copper sulfate was 0.01mol / L, and the additive sodium citrate was 0.005mol / L.

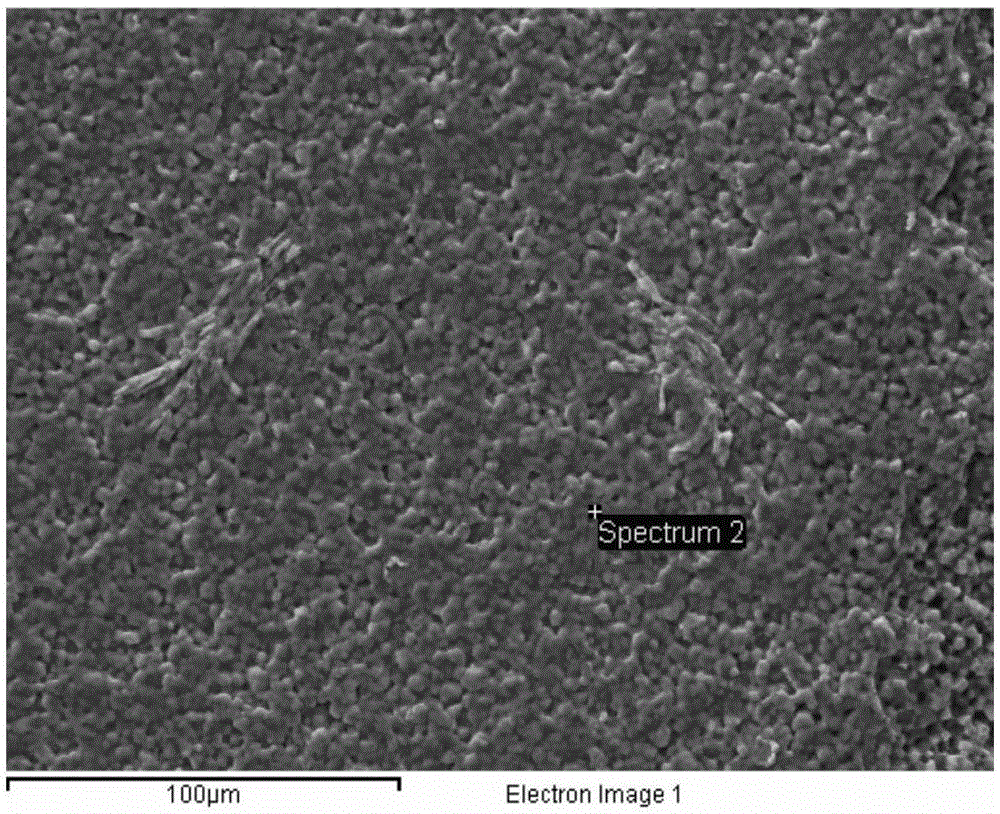

[0037] The aluminum nitride substrate with the prepared transition layer needs to be pretreated at 300°C and cooled naturally, so that the transition layer forms a un...

example 2

[0039] Example two, such as figure 2 The aluminum nitride DBC structure is shown, the ceramic thickness is 0.635mm, and the length and width are 76.2mm. Put the self-made aluminum nitride substrate into the degreasing solution and ultrasonically clean it for 10 minutes, and the surface is clean and free of oil.

[0040] The aluminum nitride substrate was placed in a NaOH solution with a concentration of 0.1mol / L for activation, and ultrasonic treatment was used for 5 minutes, ultrasonic power was 60%, and water temperature was 60°C.

[0041] Prepare a transition layer on the surface of the activated aluminum nitride substrate by dipping method. The molar content of manganese nitrate in the transition layer is 0.01mol / L, copper sulfate is 0.005mol / L, calcium nitrate and aluminum sulfate are 0.001mol / L each, additives Sodium citrate 0.005mol / L.

[0042] The aluminum nitride substrate with the prepared transition layer needs to be pretreated at 300°C and cooled naturally, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com