Method for directly preparing aniline through reaction between supported molybdenum dioxide catalyzed benzene and hydroxylamine salt

A technology of molybdenum dioxide and hydroxylamine salt, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of high price, high cost, and Complicated preparation process and other issues, to achieve good application and industrialization prospects, low cost, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

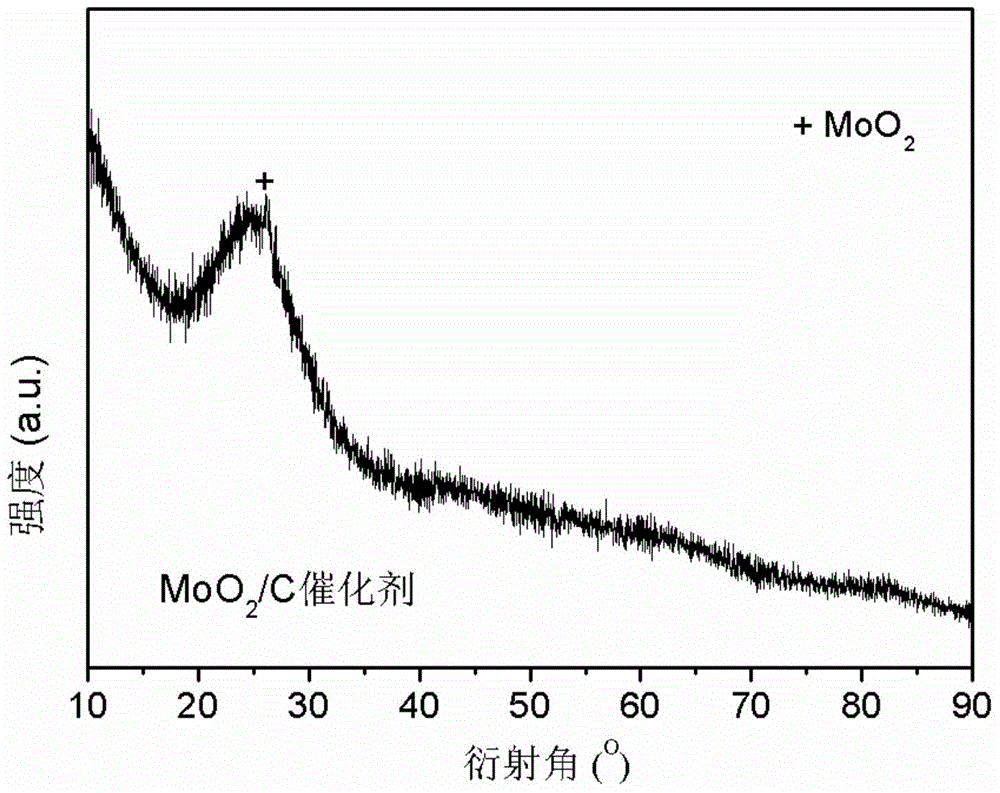

[0018] MoO 2 Preparation of / C-1# catalyst: 1.0g (0.8mmol) ammonium molybdate and 6.8g (19.9mmol) sucrose are dissolved in 60mL deionized water, and after being completely dissolved, the solution is poured into a hydrothermal kettle, and the Heat treatment at ℃ for 12 hours, after cooling down to room temperature, filter, wash with hot water until the washing liquid is neutral, and dry to obtain a brown catalyst precursor. The catalyst precursor was carbonized at 550° C. for 6 hours under a nitrogen atmosphere to finally obtain a black solid. The catalyst was subjected to thermogravimetric (TG) analysis on a Seteram Setsys 16 / 18 thermal analyzer, and it was calculated that the active components in the prepared catalyst were The mass percentage content is 6%. Since the catalyst active component MoO 2 The loading capacity is small, so in figure 1 In the XRD spectrum of the amorphous carbon, only a weaker diffraction peak appears on the steamed bun peak of amorphous carbon, wh...

Embodiment 2

[0020] MoO 2 Preparation of / C-2# catalyst: the preparation process is the same as in Example 1, except that the amount of ammonium molybdate added is 0.59g (0.5mmol), and MoO in the catalyst is calculated through thermogravimetric (TG) analysis 2 The mass percentage content is 4%.

Embodiment 3

[0022] MoO 2 Preparation of / C-3# catalyst: the preparation process is the same as in Example 1, except that the amount of ammonium molybdate added is 1.5g (1.2mmol), and MoO in the catalyst is calculated through thermogravimetric (TG) analysis 2 The mass percentage content is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com