Method for recycling protein from supernatant obtained from edible fungus through polysaccharide extraction and alcohol precipitation

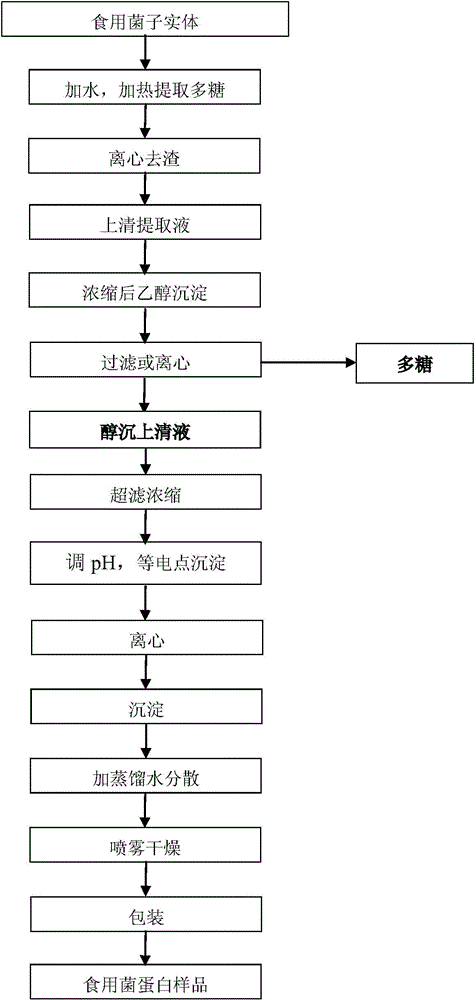

A polysaccharide extraction and supernatant technology, applied in the field of protein recovery, can solve the problems of high sewage treatment cost and insufficient protein recovery and utilization, and achieve the effects of reducing treatment cost, rich nutrition and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 1Kg of mushroom fruiting bodies, add 30L of water, heat and boil for reflux to extract for 2h, centrifuge at 5000r / m to remove slag, and heat and concentrate the supernatant extract to 25% of the original volume, and add 4 times the volume of the obtained extract concentrate to a volume fraction of 95% Ethanol precipitation, centrifugation at 10000r / m, take the supernatant, and use a 3KD molecular weight cut-off ultrafiltration membrane to carry out pressurized ultrafiltration, the pressurized pressure is 5bar, to obtain a concentrated solution, adjust the pH value with 0.1mol / L hydrochloric acid 4.3. Stir for isoelectric point precipitation, then centrifuge at 10,000 r / min, add 1 L of distilled water to 72.5 g of the obtained protein precipitate, stir and disperse, and spray dry to obtain 68.3 g of mushroom protein. The process conditions of spray drying are: the temperature of the feed port is 160-180°C, and the temperature of the discharge port is 70-90°C.

[00...

Embodiment 2

[0034] Take 1 kg of Grifola frondosa fruiting bodies, add 30 L of water, heat and boil for reflux to extract for 4 hours, centrifuge at 5000 r / m to remove slag, and heat and concentrate the supernatant extract to 25% of the original volume, and add 4 times the volume of the obtained extract concentrate to a volume fraction of 95 % ethanol alcohol precipitation, 10000r / m centrifugation, take the supernatant, and use a 5KD molecular weight cut-off ultrafiltration membrane to carry out pressurized ultrafiltration, the pressurized pressure is 4bar, to obtain a concentrated solution, adjust the pH value to 4.6, and stir for isoelectricity Spot the precipitate, then centrifuge at 10000r / min, add 78.9g of the obtained protein precipitate to stir and disperse with 1L of distilled water, and spray dry to obtain 72.6g of grifola frondosa protein. The process conditions of spray drying are: the temperature of the feed port is 160-180°C, and the temperature of the discharge port is 70-90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com