Phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant, preparation method of phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant, and flame-retardant epoxy resin prepared from phosphorus-containing nitrile/DOPO double-base structure phosphorus-containing fire retardant

An epoxy resin and flame retardant technology, applied in the field of flame retardant epoxy resin, can solve the problems of low flame retardant efficiency, poor compatibility between polymer matrix and flame retardant, and achieve high flame retardant efficiency, difficult migration, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

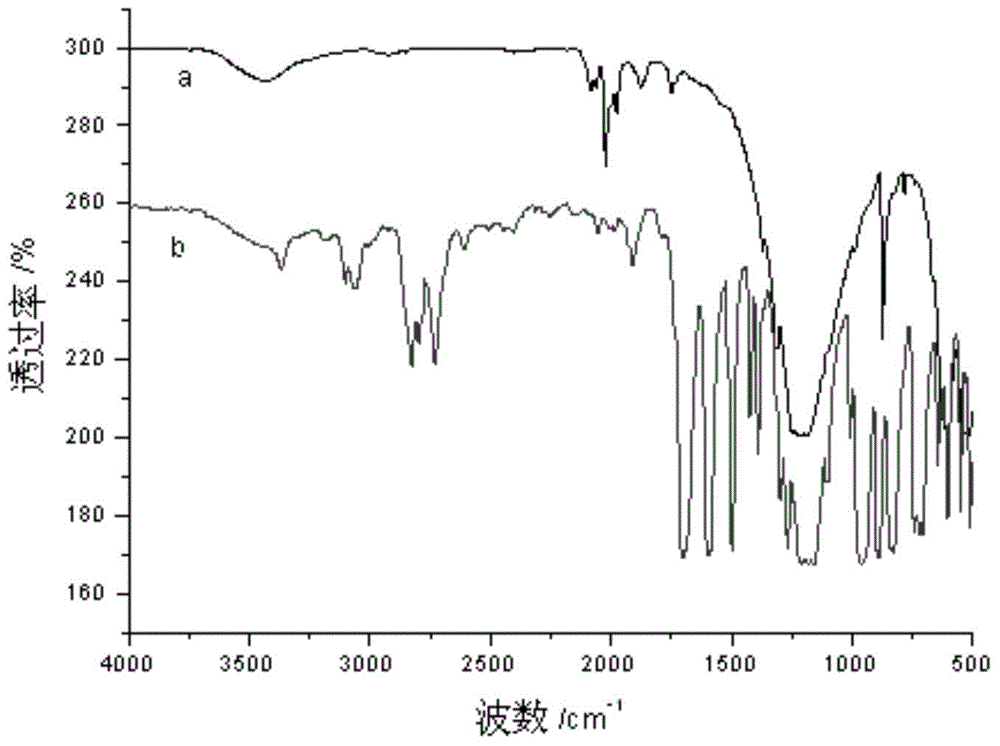

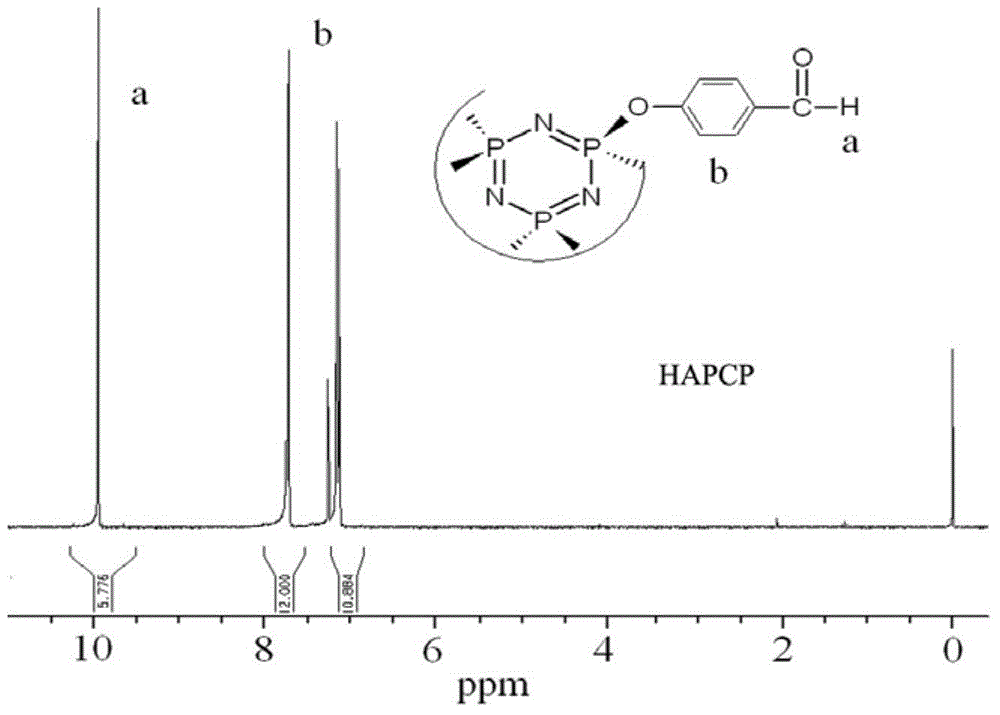

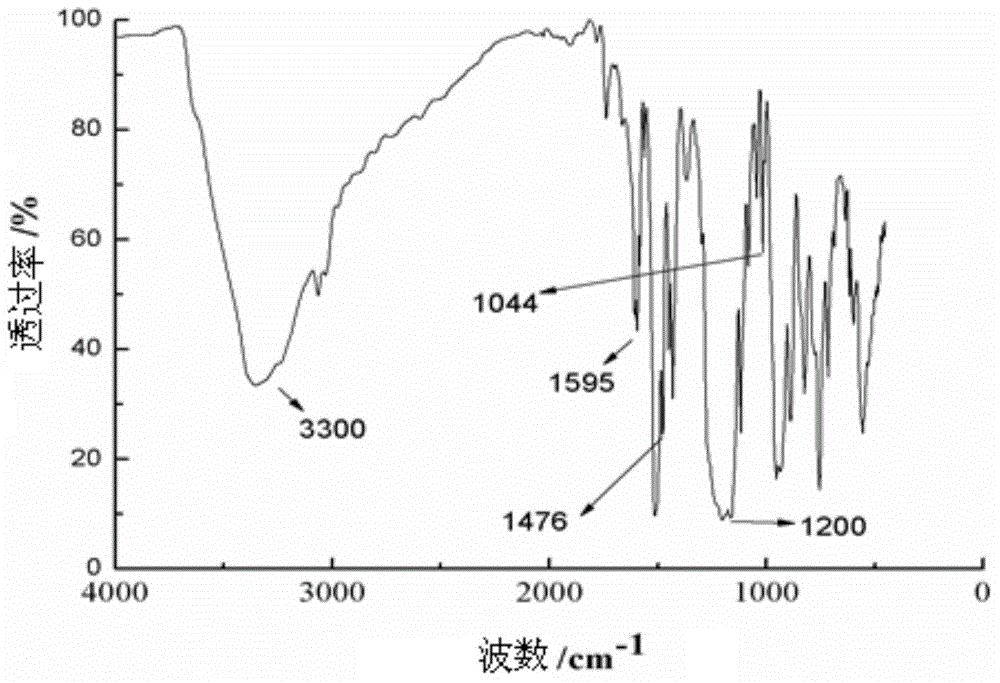

[0017] Specific implementation mode 1: The structural formula of the phosphorus-containing flame retardant containing phosphazene / DOPO double base structure in this embodiment is:

[0018]

specific Embodiment approach 2

[0019] Specific implementation mode two: the preparation method of the phosphorus-containing flame retardant containing phosphazene / DOPO double base structure in this embodiment is carried out according to the following steps:

[0020] 1. Install a spherical condenser, a nitrogen protection device, a mechanical stirrer, a constant pressure dropping funnel and a heating device on the four-necked round-bottomed flask, vacuumize the inside of the round-bottomed flask and blow in high-purity nitrogen until the flask reaches zero Oxygen anhydrous condition, then add p-hydroxybenzaldehyde into the flask, then add dried tetrahydrofuran to fully dissolve, then add triethylamine as an acid-binding agent, and stir until the reaction system is clear and transparent;

[0021] 2. Dissolve hexachlorocyclotriphosphazene in dried tetrahydrofuran to obtain solution A, and drop solution A into the continuously stirring reaction system through a constant pressure dropping funnel. The heating rat...

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 2 in that: the purity of the high-purity nitrogen in step 1 is 99.99%. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com