Method for catalyzing to generate L-theanine by using recombinant Bacillus subtilis secreted gamma-glutamyltranspeptidase

A technology of glutamyl transpeptidase and recombinant vector, which is applied in the fields of genetic engineering and enzyme engineering, can solve problems such as hidden dangers of food additives, and achieve the effects of high raw material utilization, easy control, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

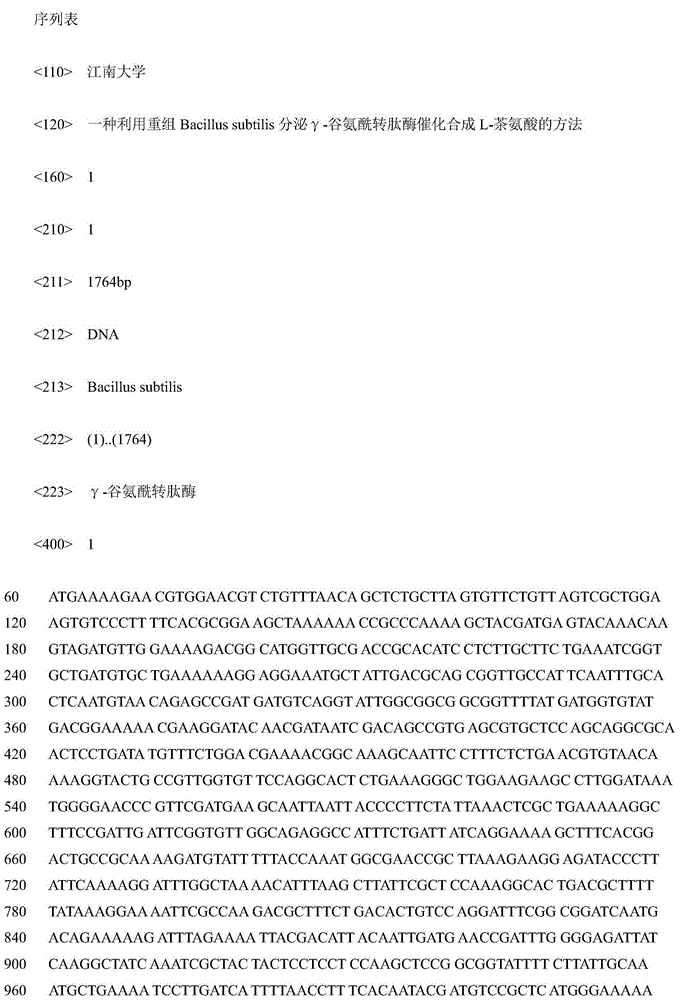

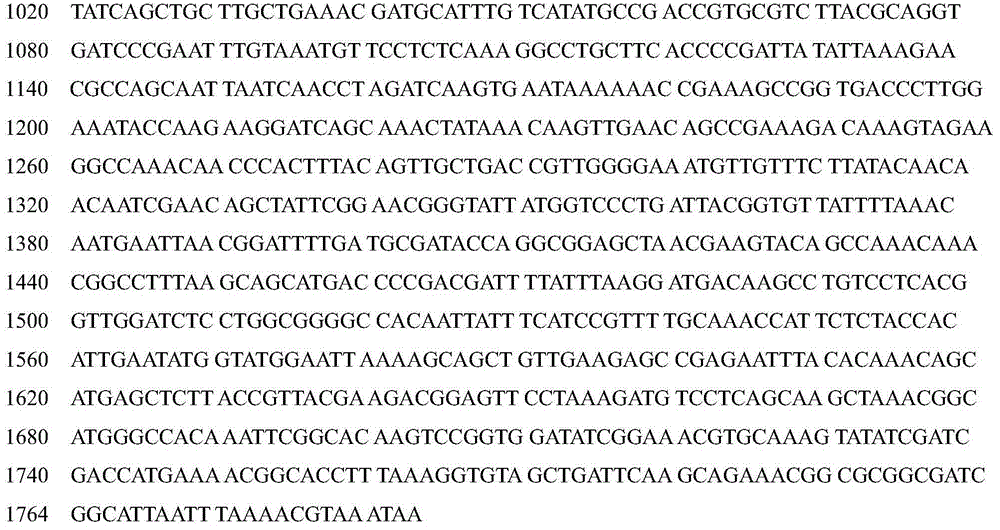

[0027] Embodiment 1: Construction of recombinant B.subtilis 168 bacterial strain

[0028] Bacillus subtilis with γ-glutamyl transpeptidase activity in the laboratory was used as the starting strain, and its chromosome was used as a template to obtain the gene of the enzyme by means of PCR, which was connected to the cloning vector to achieve a large amount of amplification of the gene. A large number of amplified GGT gene fragments were purified and connected to the pMA5 vector. After successful verification, the model strain Bacillus subtilis 168 was transformed. Positive transformants were screened on the resistance plate, inoculated with shake flasks for fermentation, and the enzyme activity in the fermentation broth was measured by colorimetry, and the enzyme was purified for L-theanine conversion. The production of theanine was detected by HPLC, indicating that the construction was successful. A recombinant strain with the ability to secrete γ-glutamyl transpeptidase was ...

Embodiment 2

[0029] Embodiment 2: the enzyme activity assay of recombinant bacterial strain

[0030] Inoculate 1% of the inoculum into 50mL / 250mL optimized medium, take the cultured bacterium solution for 60h, and centrifuge at 10,000r / min for 30min at 4°C to collect the supernatant, which contains the target protein. The enzyme activity determination method is as follows: 1ml of the standard reaction system contains 50mM borate-sodium hydroxide (pH 10), 2.5mM γ-L-glutamyl-4-nitroaniline, 60mM diglyceride, 750mM NaCl and 10 μl of appropriately diluted enzyme solution. After reacting at 37°C for 10 minutes, 2ml of 3.5N acetic acid was added to terminate the reaction. The reaction system was not added with diglycyl dipeptide as a control, and the absorbance value was measured at 410nm. The difference in absorbance between the experimental group and the control group was the transpeptidase activity. Transpeptidase activity is defined as: under standard reaction conditions, the amount of enz...

Embodiment 3

[0031] Example 3: Purification of secreted enzyme liquid from recombinant strains and its use in catalytic production of theanine

[0032] Purification method: The supernatant was filtered through a 0.45 μm filter membrane, and Ni-NTA affinity chromatography was used to achieve one-step purification. The cleaning and elution procedures of the protein were carried out in accordance with the instructions.

[0033] L-theanine conversion method: use 80mM L-glutamine as the donor, 640mM ethylamine as the acceptor, adjust the pH to 10, add GGT to a concentration of 0.6U / ml, and react at 37°C for 5 hours, 10 % trichloroacetic acid to terminate the reaction. The production of theanine was detected by HPLC. The formation of 68.9mM L-theanine was detected, and the conversion rate could reach 86%.

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com