Preparation method for ternary composites of graphene/manganese dioxide nanosheet /polyaniline nanorod

A technology of manganese dioxide and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited practical application, low specific energy density, poor cycle stability, etc., and achieve material Effects of low cost, excellent rate characteristics, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

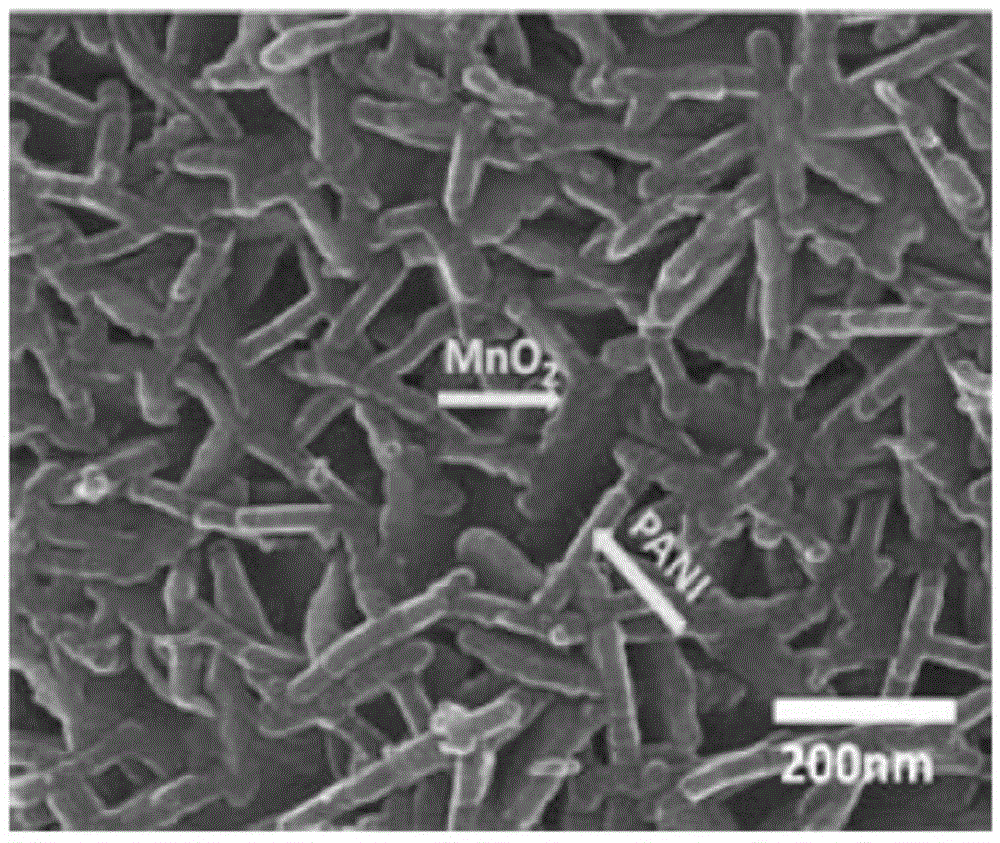

[0028] Mix the prepared 0.1M manganese acetate tetrahydrate solution and 0.1M sodium sulfate solution at a volume ratio of 1:1, then immerse the self-made graphene paper in the mixed solution, and use Autolab to electrochemically work at a constant temperature of 0.8V. Electrodeposition was carried out for 300s under high pressure conditions, then cleaned with deionized water, and dried in vacuum for 6h.

Embodiment 2

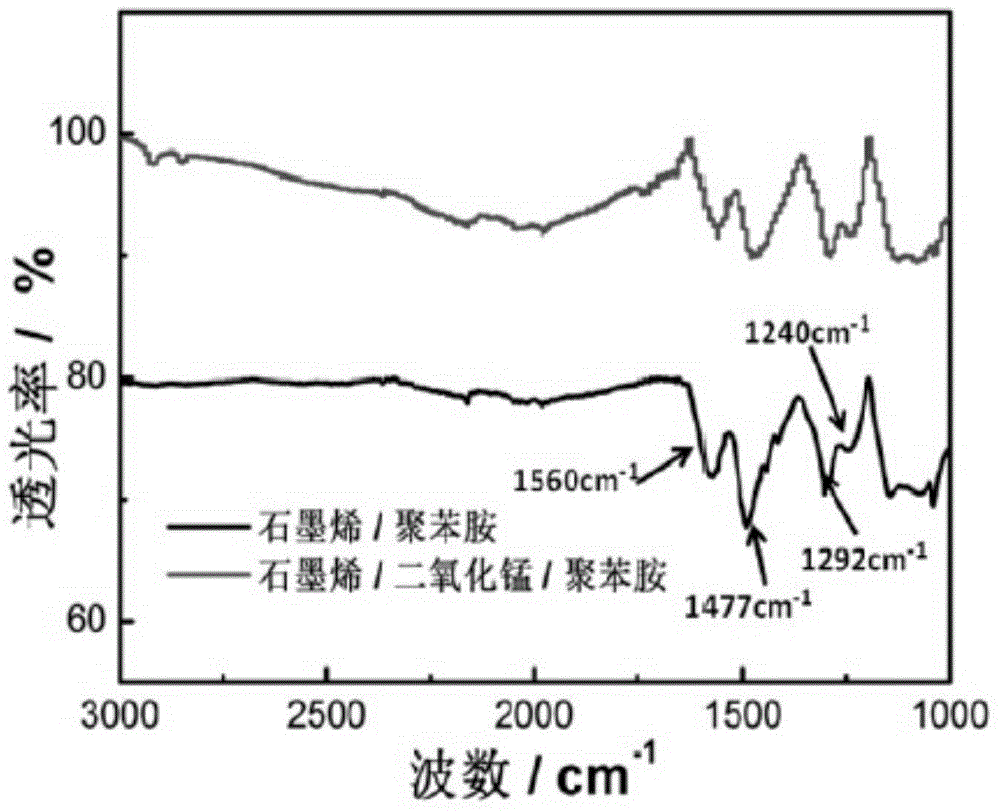

[0030]Measure 1.2ml of aniline monomer (distilled under reduced pressure before use) into 75ml of deionized water, stir for 1min, weigh 3.4g of ammonium persulfate solid, add 37.5ml of deionized water, stir for 1min, and then mix the above two solutions Together, stirred for 1 min, the graphene / manganese dioxide binary composite material prepared in Example 1 was immersed in the mixed solution, and polymerized for 3 h under static conditions.

Embodiment 3

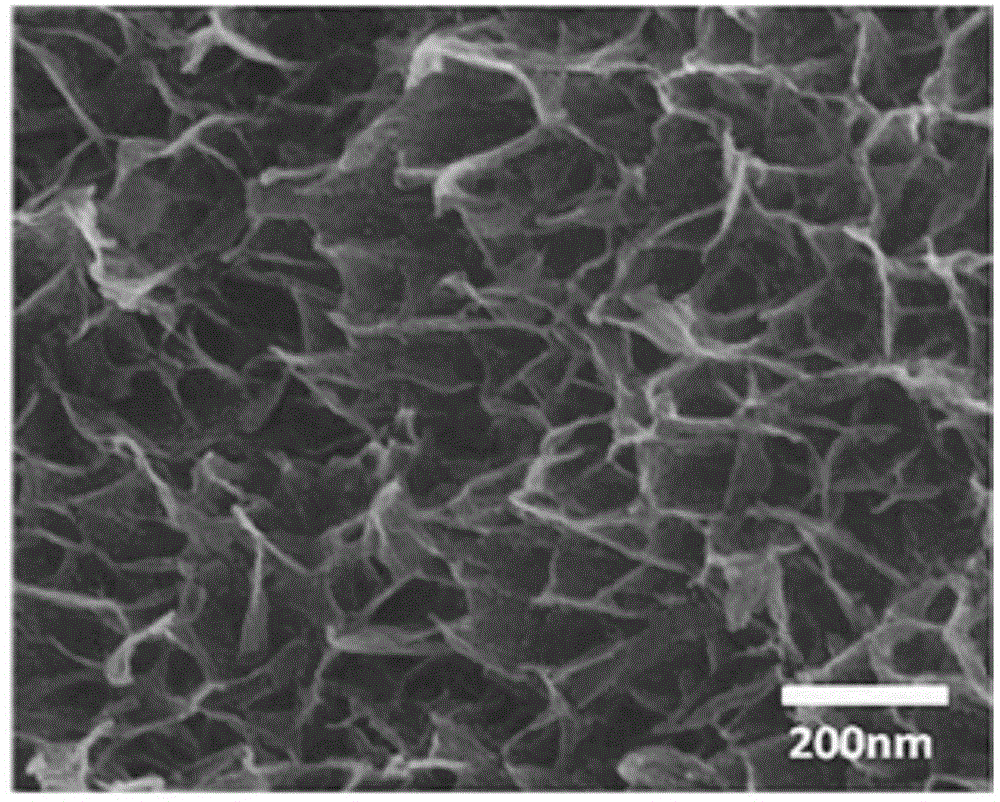

[0032] As the control group of Example 2, measure 1.2ml of aniline monomer (distilled under reduced pressure before use) into 75ml of deionized water, stir for 1min, weigh 3.4g of ammonium persulfate solid and add 37.5ml of deionized water, stir for 1min , and then the above two solutions were mixed together, stirred for 1 min, the pure graphene paper was immersed in the mixed solution, and polymerized under the same static condition for 3 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com