High-reliability image sensor packaging structure with stress protection structure

A technology of image sensor and protective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in more detail below with reference to accompanying drawing:

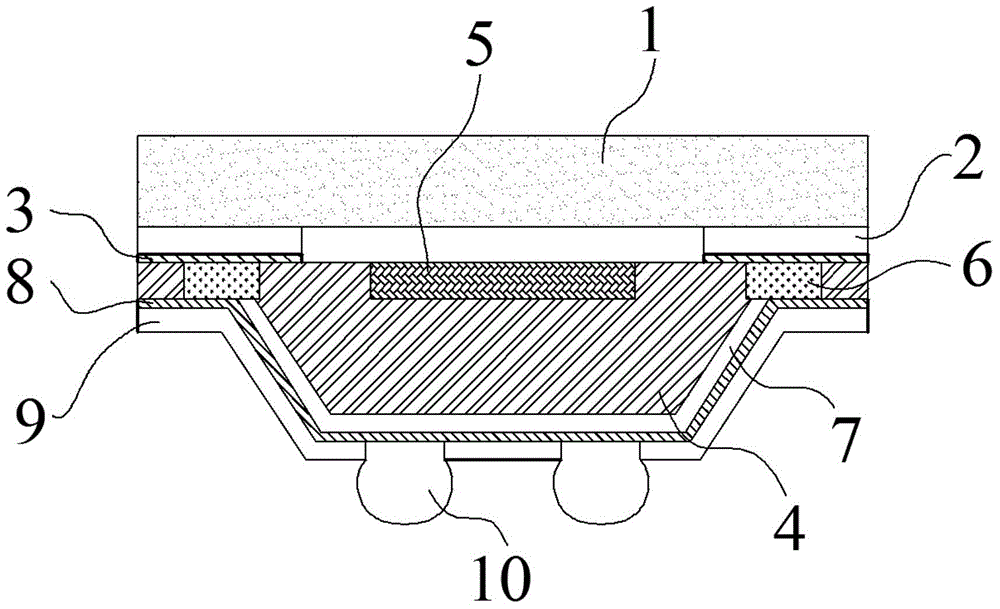

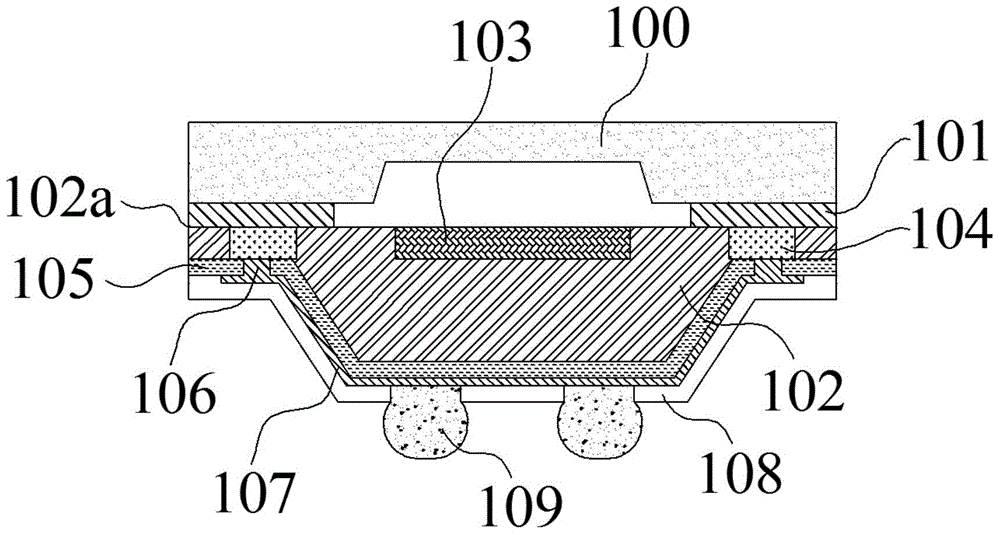

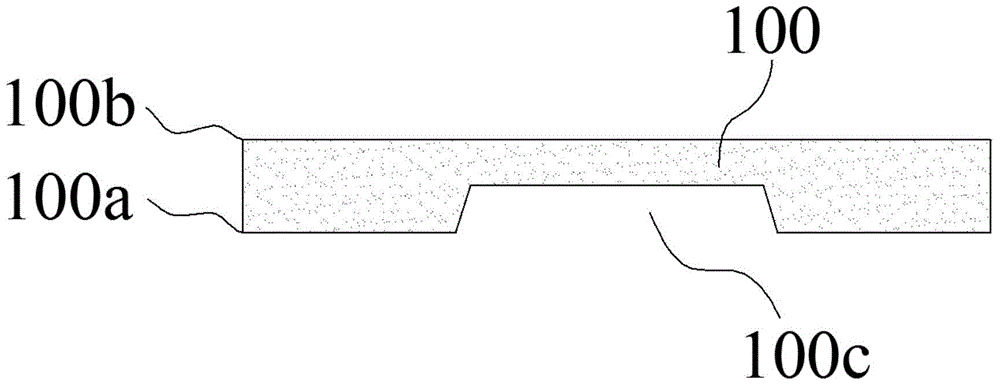

[0038] As shown in FIG. 1(b), a high-reliability image sensor package with a stress protection structure according to an embodiment of the present invention includes: 1. a cover plate 100, and a cavity structure 100c is fabricated on the front surface 100a of the cover plate; 2. .wafer 102, which comprises wafer front 102a and wafer back 102b; 3. image sensing area 103 and bonding pad 104, and described image sensing area 103 and bonding pad 104 are all distributed on wafer front 102a, wherein welding The disc 104 is distributed around the image sensing area 103, and realizes conduction; 4. The bonding glue 101 is located between the cover plate 100 and the wafer 102, and the two are bonded together; 5. The redistribution circuit layer, A passivation layer 105, a metal layer 107, and a solder resist layer 108 are sequentially formed on the back side of the wafer 102b. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com