Low subthreshold swing high withstand voltage insulated gate tunneling transistor and method of making the same

A technology of tunneling transistors and insulating gates, which is applied in the field of ultra-large-scale integrated circuit manufacturing, can solve the problems of increasing production costs, increasing process difficulty, and cannot substantially improve the tunneling probability of silicon materials, and achieves good forward withstand voltage. and the effect of reverse withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

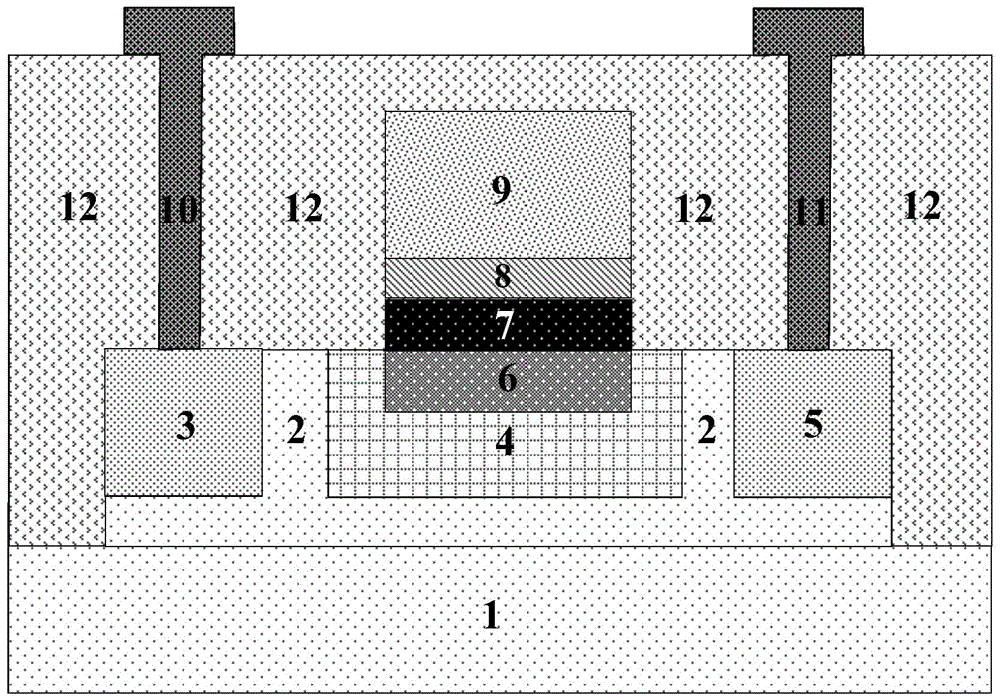

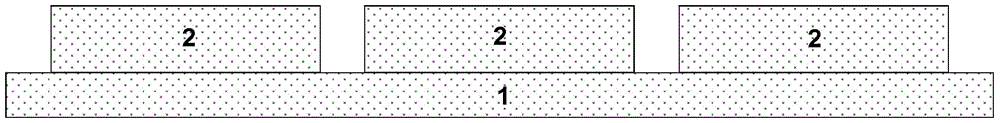

[0049] like figure 1 It is a schematic diagram of a two-dimensional structure of a low subthreshold swing high withstand voltage insulated gate tunneling transistor formed on a bulk silicon substrate in the present invention; it specifically includes a single crystal silicon substrate 1; a withstand voltage layer 2; an emitter region 3; a moderately doped Impurity base region 4; collector region 5; heavily doped base region 6; conductive layer 7; tunnel insulating layer 8; gate electrode 9; emitter 10; collector 11; blocking insulating layer 12.

[0050] Low sub-threshold swing high withstand voltage insulated gate tunneling transistor, the substrate 1 uses a single crystal silicon wafer as the substrate for forming the device, or uses an SOI wafer as the substrate for forming the device; a withstand voltage layer 2 is formed above the substrate The emitter region 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com