Alternating current electrified railway in-phase continous power supply system based on multi-port direct current transmission

A technology for multi-terminal DC power transmission and electrified railways, which is applied in parallel operation of DC power sources, power transmission AC networks, etc. It can solve problems such as train speed and traction loss, reduce line capacity, increase investment and management costs, and improve safety. and reliability, reduce investment and loss, improve response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

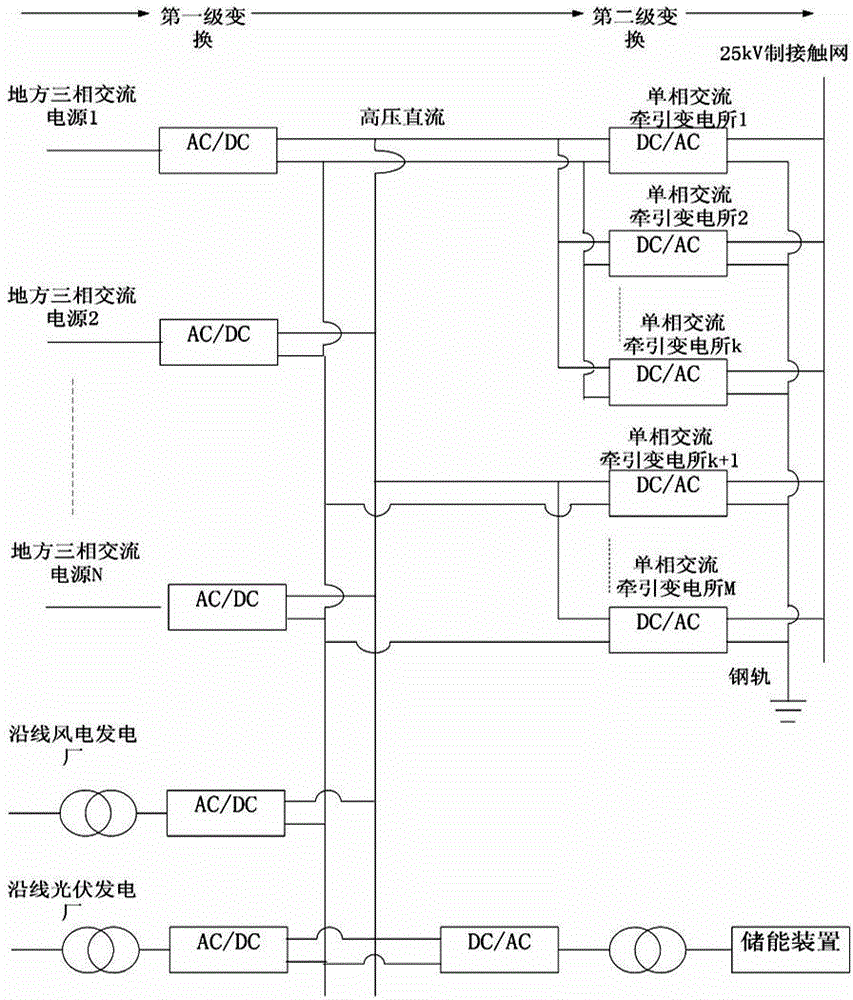

[0040] Such as figure 1 As shown, the present invention is based on the multi-terminal DC transmission AC electrified railway in-phase power supply system, including:

[0041] Three-phase high-voltage AC power supply; because the electrified railway has passed through various regions and cities, each traction substation is to get electricity from the local region 110kV / 220kV / 330kV, and this pattern is not included in the present invention. To change, that is, still including the original three-phase high-voltage AC power supply 1, the three-phase high-voltage AC power supply 2...the N power supplies of the three-phase high-voltage AC power supply N.

[0042] Direct current converter (AC-DC) is used to convert three-phase high-voltage alternating current into high-voltage direct current, that is, to convert the three-phase high-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com