Blast furnace with top-gas recycle

A top gas and blast furnace technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of reheating equipment and heating path equipment blockage, no teaching, scaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

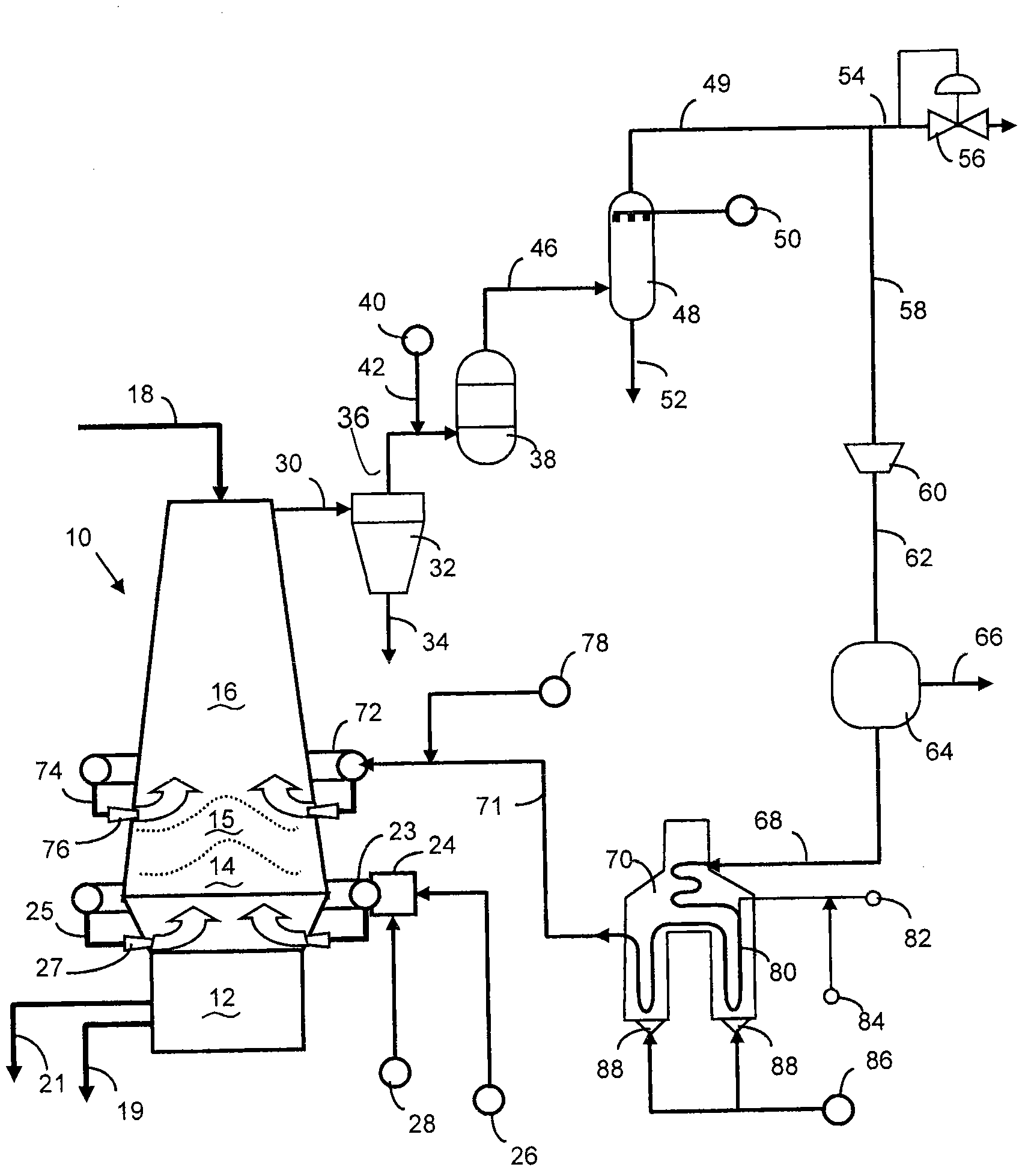

[0026] see figure 1, the numeral 10 generally denotes a blast furnace, which has a hearth section 12 for collecting molten iron and slag, a blast section 14 for introducing oxygen-containing gas to achieve coke combustion, and a shaft section 16 in which iron ore The particles are charged in the form of sinter, pellets or lump ore and mixtures thereof together with coke, limestone and other fluxes 18, and then, as is known in the art, the iron oxides are reduced to wustite and eventually metal iron. Molten iron 19 and slag 21 are periodically discharged from the bottom region 12 of the blast furnace 10 .

[0027] Oxygen-replacing air of industrial purity from source 26 is delivered to mixing device 24 where it is delivered from source 28 to prevent the flame temperature from reaching excessive levels and thus preventing damage to the blast nozzles in the tuyeres 27 Moderate agent (temperature moderating agent). The temperature moderating agent 28 may be, for example, steam,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com