Peanut milk product and preparation method thereof

A technology for dairy products and peanuts, applied in dairy products, milk preparations, applications, etc., can solve problems such as unsatisfactory, unsaturated fatty acid oxidation, etc., and achieve the effect of solving easy oxidation, meeting taste requirements, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

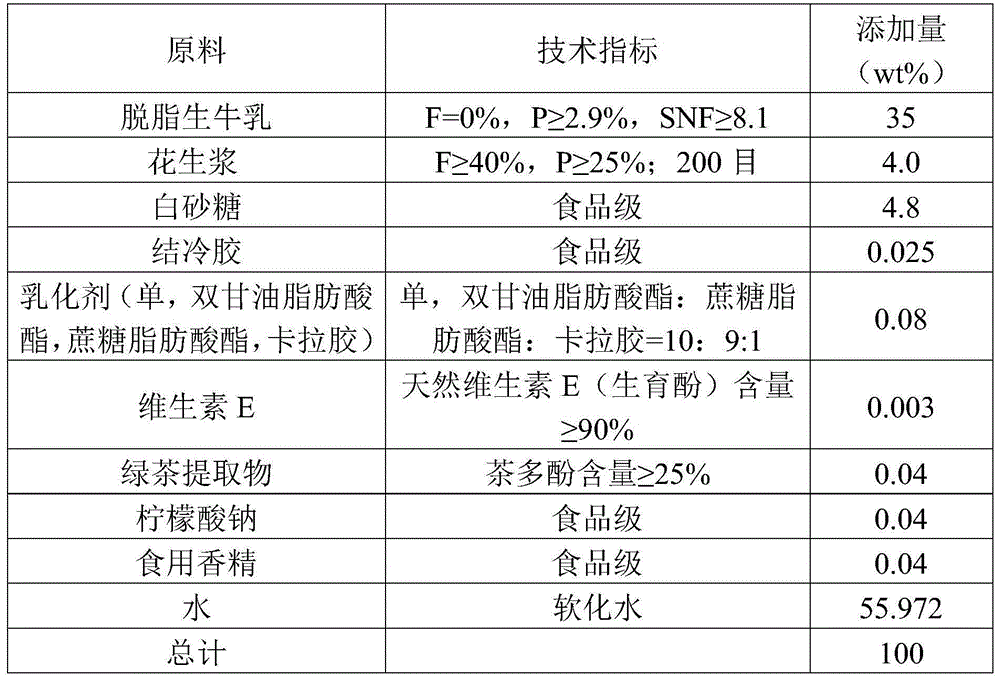

[0048] 1. Raw material formula (see Table 1).

[0049] The raw material formula of table 1 embodiment 1

[0050]

[0051] 2. Preparation method:

[0052] (1) Mix peanut pulp, white granulated sugar and water (70°C, 10min), and filter through a 120-mesh filter to obtain feed solution A. The amount of water used is to make the quality of feed solution A reach 50% of the final product Required usage amount; Described mixing is agitation and mixing;

[0053] (2) Mix raw milk, thickener, emulsifier, sodium citrate and remaining water (75°C, 10 min), and filter through an 80-mesh filter to obtain feed liquid B; the mixing is stirring and mixing;

[0054] (3) Mix feed liquid A, feed liquid B, vitamin E, green tea extract, and food flavor (60°C, 10 min), and vacuum degas the resulting mixture and homogenize (primary pressure 15 MPa, secondary pressure 5 MPa, Homogeneous temperature 50 DEG C); Described mixing is agitation mixing;

[0055] (4) Ultra-high temperature sterilizatio...

Embodiment 2

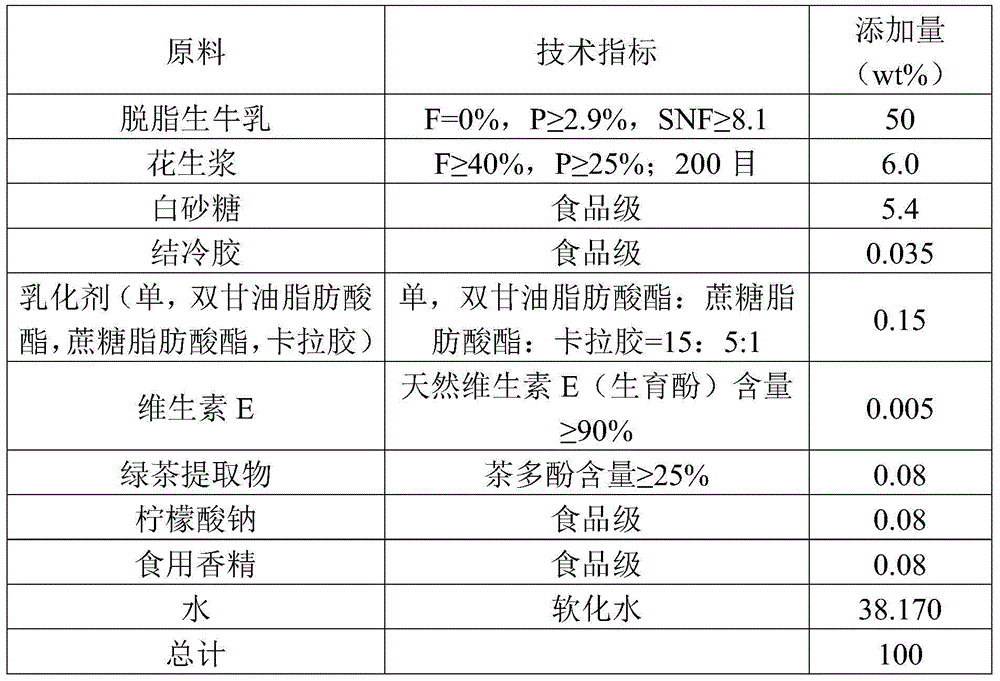

[0058] 1. Raw material formula (see Table 2).

[0059] The raw material formula of table 2 embodiment 2

[0060]

[0061] 2. Preparation method:

[0062] (1) Mix peanut pulp, white granulated sugar and water (75°C, 15min), and filter through a 200-mesh filter screen to obtain feed solution A. The amount of water used is to make the quality of feed solution A reach 40% of the final product Required usage amount; Described mixing is agitation and mixing;

[0063] (2) Mix raw milk, thickener, emulsifier, sodium citrate and the remaining water (80°C, 15min), and filter through a 120-mesh filter to obtain feed liquid B; the mixing is stirring and mixing;

[0064] (3) Mix feed liquid A, feed liquid B, vitamin E, green tea extract and edible essence (70°C, 15 min), and vacuum degas the obtained mixed liquid, homogenize (primary pressure 20MPa, secondary pressure 10MPa, Homogeneous temperature 70 ℃); Described mixing is agitation mixing;

[0065] (4) Ultra-high temperature ster...

Embodiment 3

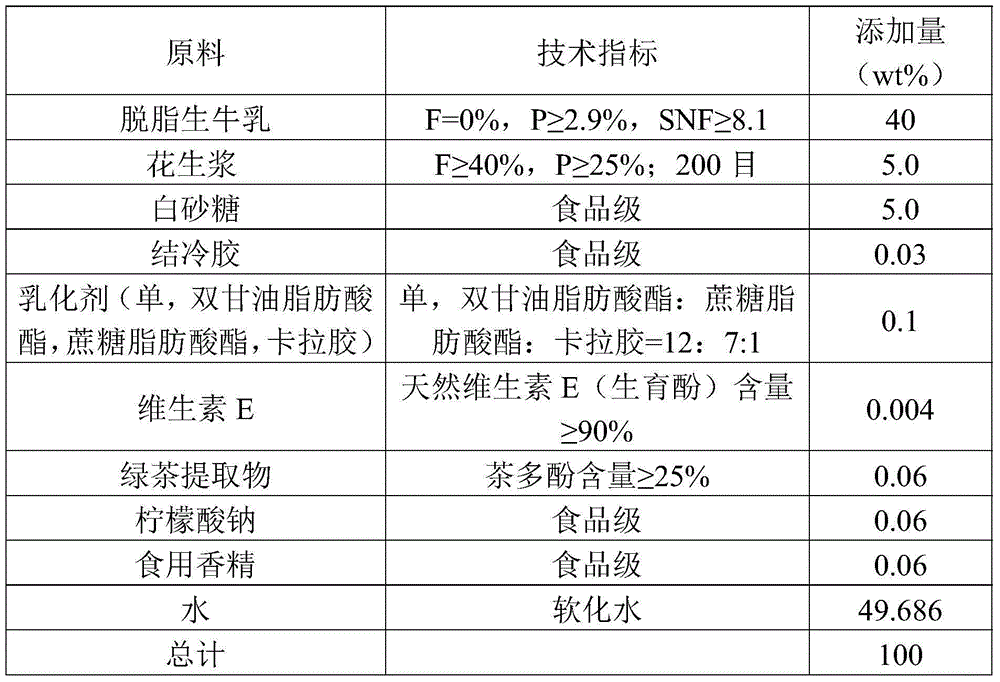

[0068] 1. Raw material formula (see Table 3).

[0069] The raw material formula of table 3 embodiment 3

[0070]

[0071] 2. Preparation method:

[0072] (1) Mix peanut pulp, white granulated sugar and water (75°C, 10min), filter through a 120-mesh filter to obtain feed solution A, and use the amount of water so that the quality of feed solution A reaches 60% of the final product Required usage amount; Described mixing is agitation and mixing;

[0073] (2) Mix raw milk, thickener, emulsifier, sodium citrate and the remaining water (80°C, 10min), and filter through a 120-mesh filter to obtain feed liquid B; the mixing is stirring and mixing;

[0074] (3) Mix feed liquid A, feed liquid B, vitamin E, green tea extract, and food flavor (65°C, 15 min), and vacuum degas the resulting mixture and homogenize (primary pressure 15MPa, secondary pressure 10MPa, Homogeneous temperature 60 ℃); Described mixing is agitation mixing;

[0075] (4) Ultra-high temperature sterilization (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com