Enteric-coated gelatine empty capsules and preparation method thereof

A technology of hollow capsules and enteric-coated gelatin, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of waste of resources, air pollution, capsule shell residue, etc., to improve costs and facilitate printing , the effect of residual reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

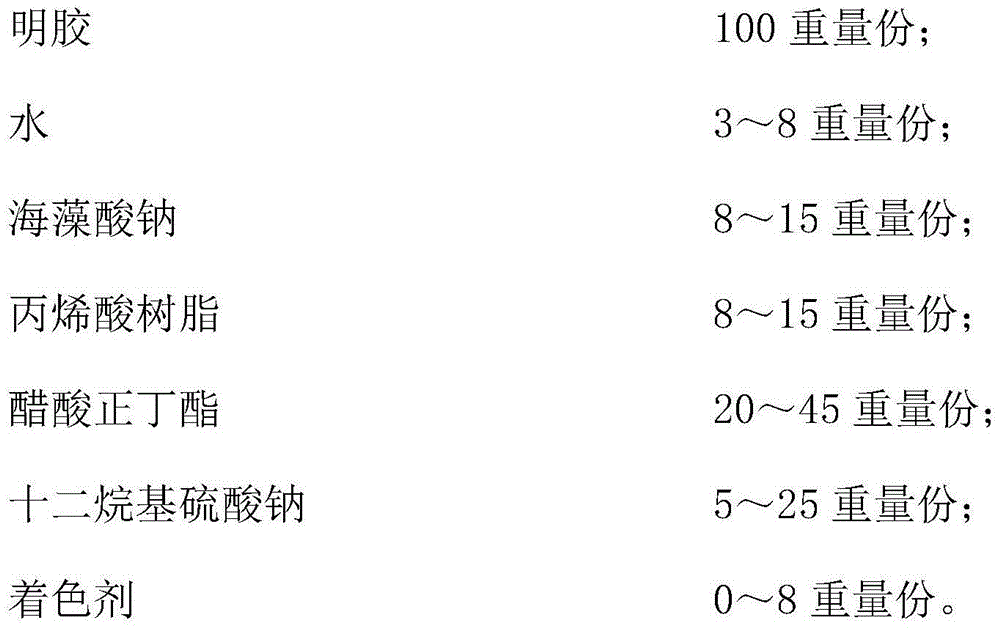

[0024] A kind of enteric-coated gelatin hollow capsule embodiment 1 of the present invention comprises the following components, and each component is respectively according to parts by weight:

[0025]

[0026] The preparation method of this enteric-coated gelatin hollow capsule is as follows: add gelatin and water into the reaction kettle, steam for 30-40 minutes, control the temperature at 20-30°C, raise the temperature to 70-85°C, stir well, and slowly add Sodium lauryl sulfate, continue to stir for 25-40 minutes, add sodium alginate, continue to stir evenly, and let it stand for 2-3 hours to react; then send it to the capsule production line for dipping and molding to obtain gelatin hollow capsule material; The mixture of n-butyl acetate and n-butyl acetate is coated on the surface of the obtained gelatin hollow capsule material, stirred vigorously, and then dried. The drying temperature is 60-80°C, and the drying time is 0.5-2h. During the drying process, After being ...

Embodiment 2

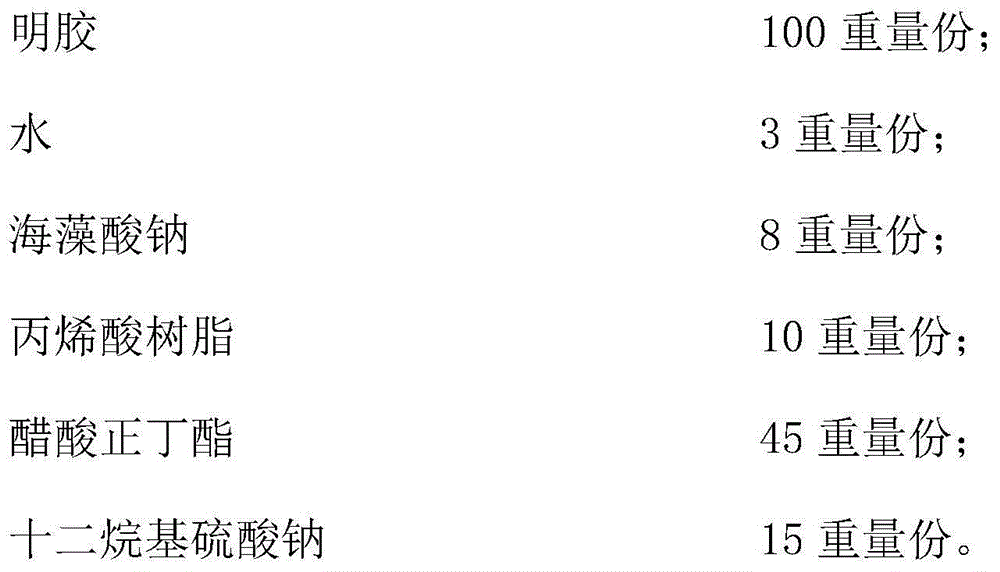

[0027] A kind of enteric-coated gelatin hollow capsule embodiment 2 of the present invention comprises the following components, and each component is respectively according to parts by weight:

[0028]

[0029]

[0030] The preparation method of this kind of enteric-coated gelatin hollow capsule is the same as that of Example 1.

Embodiment 3

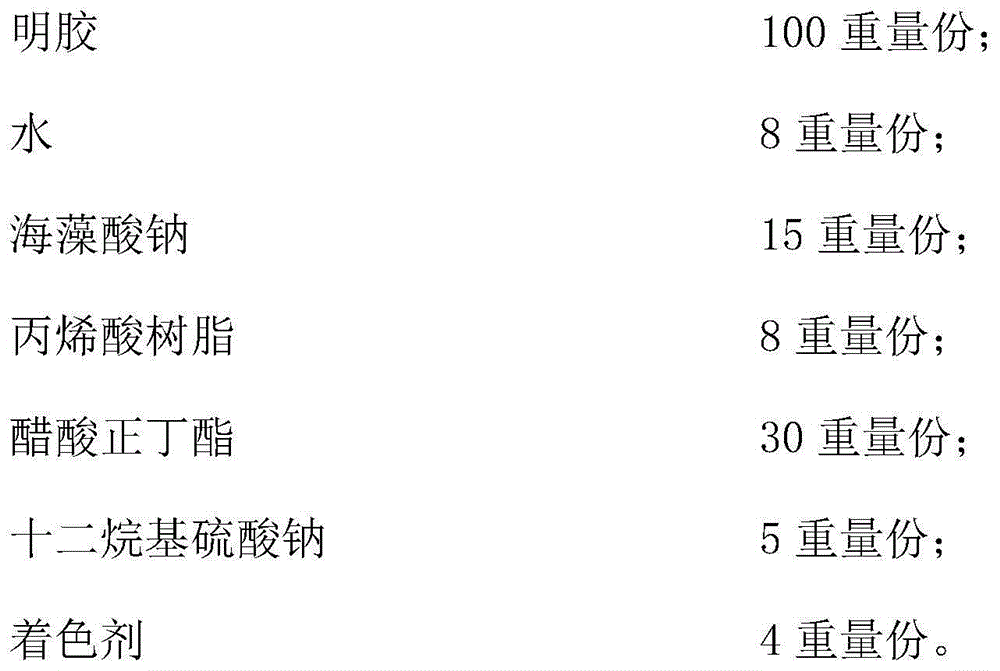

[0031] A kind of enteric-coated gelatin hollow capsule embodiment 3 of the present invention comprises the following components, and each component is respectively according to parts by weight:

[0032]

[0033] The preparation method of this kind of enteric-coated gelatin hollow capsule is the same as that of Example 1.

[0034] The enteric-coated gelatin hollow capsule comparative example in the prior art comprises the following components, and each component is respectively according to parts by weight:

[0035]

[0036] The preparation method of this kind of enteric-coated gelatin hollow capsule is as follows: Stir the gelatin and water evenly, heat to 70-75°C, then add sodium lauryl sulfate, stir evenly, let it stand for 4-5 hours, and then send it to the capsule production line Carry out glue dipping and molding; then soak in the mixture of acrylic resin, acetone and colorant, and then dry at a temperature of 30°C for 3 to 4 hours, and finally solidify, cool and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com