Preparation method of ABC dry powder extinguishing agent

A dry powder fire extinguishing agent, monoammonium phosphate technology, applied in fire protection equipment and other directions, can solve the problems of low fire extinguishing efficiency, large smoke release, low efficiency, etc., and achieve the effect of high moisture-proof and anti-caking performance, reduced smoke release and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

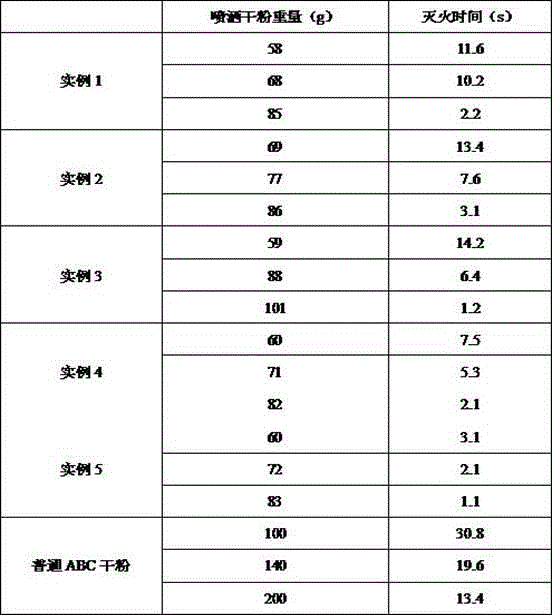

Examples

example 1

[0023] (1) Add 50g of monoammonium phosphate, 9g of ammonium sulfate, 4g of nano-silica, 2g of sodium bentonite, 1g of muscovite, 1g of melamine, 0.1g of carbon nanotubes, 3g of graphite, 1g of ammonium polyphosphate and vinyl triethoxy Mix 0.2g of methyl silane in a 250ml three-necked flask according to the weight ratio, raise the temperature of the mixture to 70°C, spray methylphenyl silicone oil into the above mixture with a silicone oil pump, add 0.3g of manganese hypophosphite, 0.4g of phosphomolybdic acid, di 0.2 g of pyridine nucleotide phosphate and 0.1 g of dihydroxybismuth nitrate were stirred at 60°C for 30 minutes to obtain product D;

[0024] (2) Use a continuous modification coating machine to crush the product D until more than 80% of the particle size is less than 30 microns, stir at 300rpm at 60°C for 20min, dry the product at 90°C for 2h, cool down to 30°C, and cool In 10 minutes, ABC dry powder fire extinguishing agent is obtained;

[0025] Carbon nanotubes...

example 2

[0027] (1) Add 75g of monoammonium phosphate, 12g of ammonium sulfate, 10g of nano-silica, 3g of calcium-based bentonite, 3g of phlogopite, 1.5g of melamine, 0.3g of carbon nanotubes, 5g of graphite, 7g of ammonium polyphosphate and vinyltrimethoxy Mix 0.3g of silane in a 250ml three-necked flask according to the weight ratio, raise the temperature of the mixture to 90°C, spray simethicone into the above mixture, add 0.5g of manganese hypophosphite, 0.7g of phosphomolybdic acid, and pyridine nucleoside diphosphate 0.7 g of acid and 0.2 g of dihydroxybismuth nitrate were stirred and reacted at 90°C for 50 minutes to obtain product D;

[0028] (2) Use a continuous modified coating machine to crush the product D until more than 80% of the particle size is less than 30 microns, stir at 60°C at 1000rpm for 40min, dry the product at 100°C for 4h, cool down to 30°C, and cool After 20 minutes, ABC dry powder fire extinguishing agent is obtained;

[0029] Carbon nanotubes are double-w...

example 3

[0031] (1) Add 62g of monoammonium phosphate, 10.5g of ammonium sulfate, 7g of nano-silica, 2.5g of hydrogen-based bentonite, 2g of muscovite, 1.2g of melamine, 0.2g of carbon nanotubes, 4g of graphite, 4g of ammonium polyphosphate and vinyl Mix 0.25g of triethoxysilane in a 250ml three-necked bottle according to the weight ratio, heat the mixture to 80°C, spray methylphenyl silicone oil into the above mixture, add 0.4g of manganese hypophosphite, 0.5g of phosphomolybdic acid, 0.5 g of pyridine nucleotide phosphate and 0.15 g of dihydroxybismuth nitrate were stirred and reacted at 75°C for 40 minutes to obtain product D;

[0032] (2) Use a continuous modification coating machine to crush the product D until more than 80% of the particle size is less than 30 microns, stir at 60°C at 650rpm for 30min, dry the product at 95°C for 3h, cool down to 30°C, and cool After 15 minutes, ABC dry powder fire extinguishing agent is obtained;

[0033] Carbon nanotubes are multi-walled carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com