Preparation and purification methods of quaternary ammonium salt type dimeric surfactant

A gemini surface and purification method technology, applied in chemical instruments and methods, preparation of functional groups substituted with amino groups, purification/separation of amino compounds, etc., to reduce production costs, high yield, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

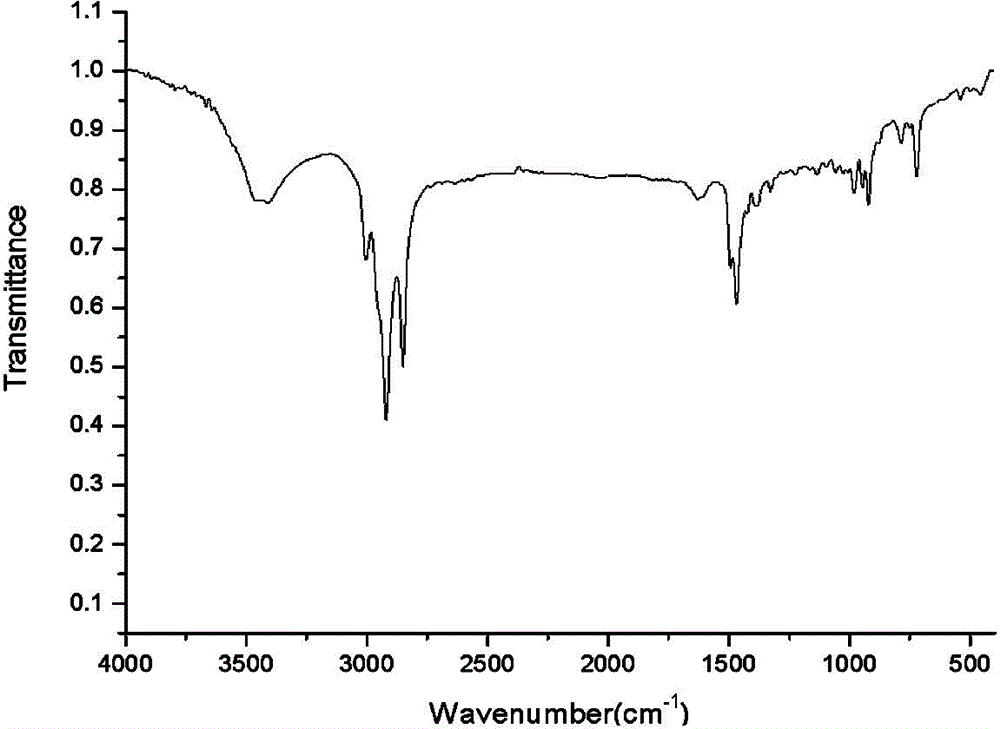

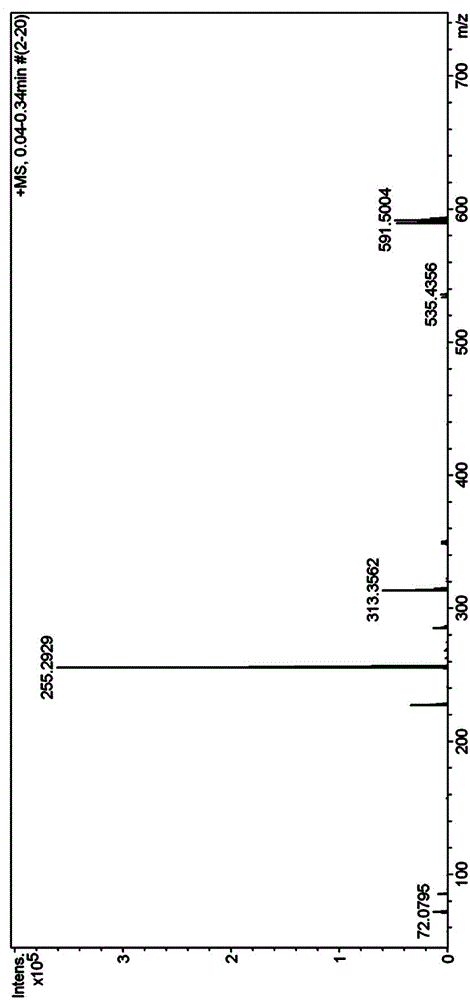

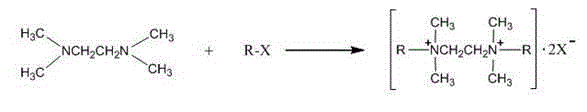

[0021] C 12 -2-C 12 Synthesis.

[0022] In a 100 mL three-necked flask equipped with a thermometer and magnetic stirring, add 7.4 mL (0.05 mol) of N,N,N',N'-tetramethylethylenediamine and 38.2 g (0.15 mol) of α-bromododecane Alkanes, constant temperature at 70 ℃, fully stirred, continue to react for 10h, stop heating. The mixture was filtered, recrystallized with a mixed solvent of ethanol: acetone = 1:3, and dried to obtain a refined product with a yield of 89.3%.

Embodiment 2

[0024] C 14 -2-C 14 Synthesis.

[0025] In a 100mL three-necked flask equipped with a thermometer and magnetic stirring, add 7.4mL (0.05mol) of N,N,N',N'-tetramethylethylenediamine and 41.6g (0.15mol) of α-bromotetradecane , keep the temperature at 75°C, stir well, continue the reaction for 12h, stop heating. The mixture was filtered and recrystallized with a mixed solvent of ethanol: acetone = 1:3 to obtain a refined product with a dry yield of 91.6%.

Embodiment 3

[0027] C 6 -2-C 6 Synthesis.

[0028] In a 100mL three-necked flask equipped with a thermometer and magnetic stirring, add 7.4mL (0.05mol) of N,N,N',N'-tetramethylethylenediamine and 12.1g (0.10mol) of α-chloro-n-hexane, Keep the temperature at 50°C, stir well, continue the reaction for 15h, and stop heating. The mixture was filtered and recrystallized with a mixed solvent of petroleum ether: acetone = 3:1 to obtain a refined product with a dry yield of 92.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com