Multistage parallel intensified fixed bed reactor and using method thereof

A fixed-bed reactor and fixed-bed technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high pressure drop, low mass transfer rate, slow material flow rate, etc. in the fixed bed reactor, and achieve a compact structure. , The effect of high reaction efficiency and fast surface update

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

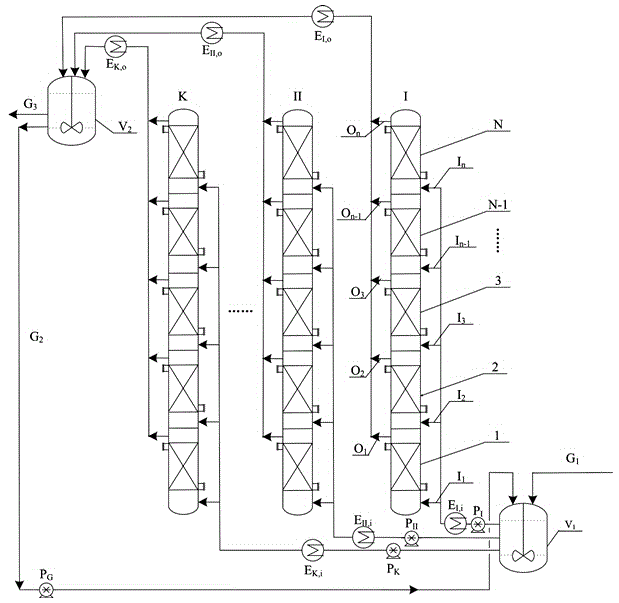

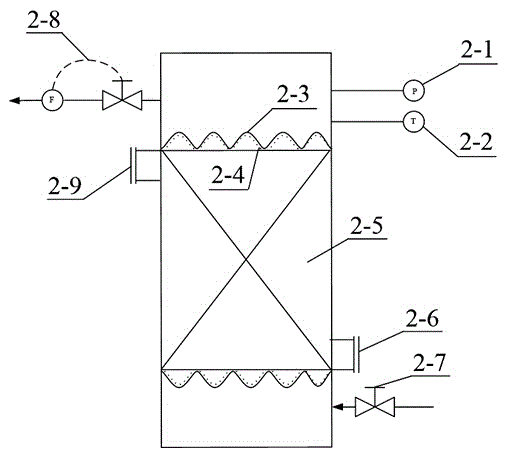

[0030] Refer below figure 1 , 2 Describe the multi-stage parallel reinforced fixed bed reactor according to the embodiment of the present invention and its use method

[0031] In the multi-stage parallel enhanced fixed bed reactor of the embodiment of the present invention, the reaction units are connected in parallel and the bed is divided into sections. Under the forced drive of the circulation pump, the liquid flow is evenly sent to each catalyst bed, and flows from the bottom to the bottom. Pass through the catalyst bed at a set speed and temperature. On the liquid flow input and output pipelines, install appropriate temperature control and flow control equipment and instruments, such as cold and heat exchangers, valves, flow meters, thermometers, etc. In this way, the pressure drop of the bed can be effectively reduced, the material velocity can be greatly increased, the phenomenon of oil-water phase and split flow can be eliminated, and the purpose of increasing the ma...

experiment example 1

[0057] Experimental example 1:A manufacturer who produces cyclohexanol by hydration of cyclohexene has a production capacity of 8000t / y. Originally, a series fixed-bed reactor was used, and the temperature in the tower kettle reached 200°C. The pressure drop is too high, the mass flow rate is 5t / h, after 6 hours of reaction, the conversion rate of cyclohexene is 7.5%, and the selectivity of cyclohexanol is 85%. And adopt this device to produce, raw material enters each reaction unit by raw material tank, feed ratio: the mass ratio of cyclohexene and water is 1:3.2, is delivered to each reaction unit by delivery pump, and total mass flow is: F= 20t / h. According to the reaction situation and the physical properties of the materials, the manufacturer adopts 4 reaction units, and each reaction unit is connected with 5 fixed bed sections in parallel, and the feed rate of each bed section is 1t / h. The pressure drop of the reaction material passing through the catalyst bed is only...

experiment example 2

[0058] Experimental example 2: A manufacturer in a certain place that produces β-caryophyllene alcohol by hydration of β-caryophyllene has a production capacity of 1800t / y. It used to use an integrated fixed bed reactor. The pressure drop was 2.5MPa, the mass flow rate was 1.2t / h, and after 1 hour of reaction, the conversion rate of β-caryophyllene was 16%, and the selectivity of β-caryophyllene alcohol was 86%. And adopt this device to carry out production, raw material enters each reaction unit by raw material tank, feed ratio: the mass ratio of β-caryophyllene and water is 1:1, is transported to each reaction unit by delivery pump, and total mass flow rate is: F =3t / h. According to the reaction situation, the manufacturer adopts 2 reaction units, each reaction unit is connected with 6 fixed bed sections in parallel, and the feed rate of each bed section is 0.25t / h. The pressure drop of the reaction material passing through the catalyst bed is only 0.5MPa. After heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com