Preparation method of propenyl ethanoate catalyst and synthesis method of propenyl ethanoate

A technology of allyl acetate and a synthesis method, which is applied in the directions of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of low activity and selectivity of allyl acetate catalysts, and achieves improved activity and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

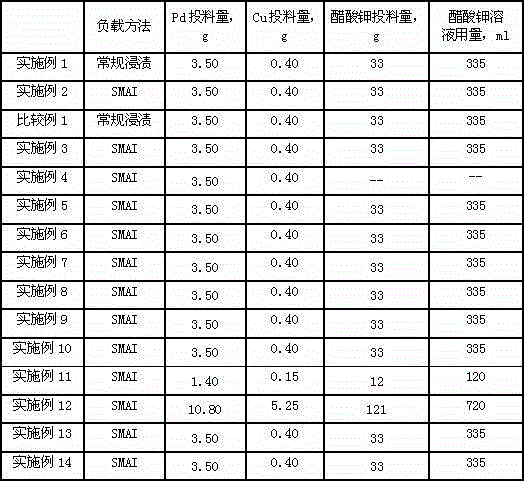

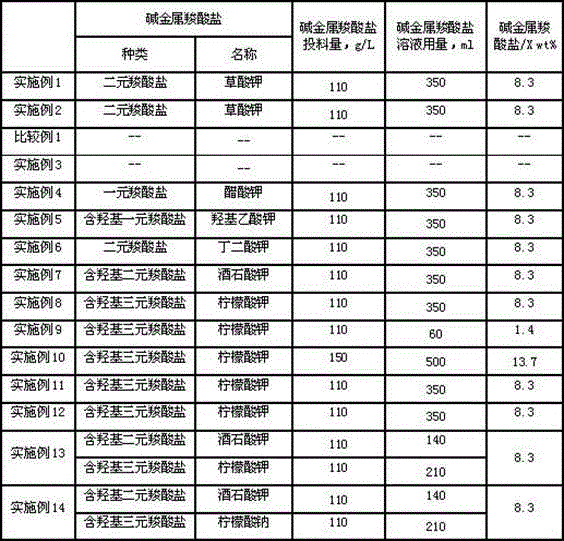

Embodiment 1

[0026] Preparation of modified carrier: Spray 350ml of 110g / L potassium oxalate aqueous solution evenly on 1.1L spherical SiO2 with a diameter of 5.6mm 2 on the carrier and dried to obtain a modified carrier (X), wherein the alkali metal carboxylate accounted for 8.3 wt% of the modified carrier.

[0027] The preparation of supported catalyst: use sodium bicarbonate pH regulator and water as solvent preparation pH to be 1.05, containing 3.50gPd and 0.40gCu chloropalladic acid, cupric chloride aqueous solution, obtain impregnating liquid 560ml, it is mixed in the pot impregnated on the carrier (X), dried at 80°C, and 105ml contains 21.5g Na 2 SiO 3 9H 2 The solution of O is fully mixed, aged for 24h, and then used with a solubility of 10% (in the form of N 2 h 4 ·H 2 (2 in weight ratio) was reduced with 550ml of hydrazine hydrate, washed with water, and dried at 90°C to obtain B, and 335ml of a solution containing 33g of potassium acetate was weighed, impregnated on B, and...

Embodiment 2

[0030] for 【Example 1】 comparative example.

[0031] Preparation of modified carrier: Spray 350ml of 110g / L potassium oxalate aqueous solution evenly on 1.1L spherical SiO2 with a diameter of 5.6mm 2 on the carrier and dried to obtain a modified carrier (X), wherein the alkali metal carboxylate accounted for 8.3 wt% of the modified carrier.

[0032]Preparation of supported catalyst: Weigh 3.50g of metal palladium and 0.40g of metal copper into a crucible fixed between the electrodes of Knotes-927500 static metal atom reactor, evacuate the system to 0.002Pa, and cool with liquid nitrogen Reaction flask to -200°C; introduce 10ml of toluene into the reaction flask to fill the inner wall of the reaction flask, increase the current to evaporate Pd and Cu, and continuously introduce toluene to co-condense gaseous Pd and Cu atoms with toluene in the reaction flask Wall; the temperature is raised to -80°C, the coacervate melts and falls to the bottom of the reaction bottle to obtai...

Embodiment 3

[0041] for [Comparative Example 1] comparative example.

[0042] Preparation of the supported catalyst: Weigh 3.50g of metal palladium and 0.40g of metal copper and put them into a stationary Knotes-927500

[0043] In the crucible between the electrodes of the type metal atom reactor, the system is evacuated to 0.002Pa, and the reaction bottle is cooled to -200°C with liquid nitrogen; 10ml of toluene is introduced into the reaction bottle to fill the inner wall of the reaction bottle, and the current is increased. , to evaporate Pd and Cu, and continuously introduce toluene, so that gaseous Pd, Cu atoms and toluene co-condense on the wall of the reaction bottle; when the temperature is raised to -80°C, the co-condensates melt and fall into the bottom of the reaction bottle to obtain a solution, and the obtained solution is immersed in 1.1L spherical SiO with a diameter of 5.6mm 2 On the support (X), the temperature is raised to 30°C, and the catalyst precursor A is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com