Rotary kiln selenium distillation system

A technology of rotary kiln and selenium steaming, which is applied in the field of metallurgy, can solve the problem that the output of selenium preparation cannot meet the requirements of selenium, and achieve the effect of low pollution and high heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

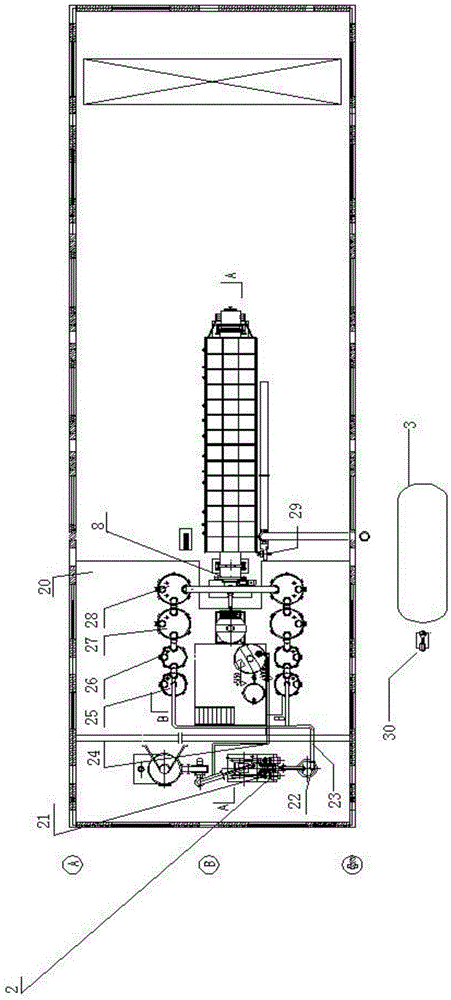

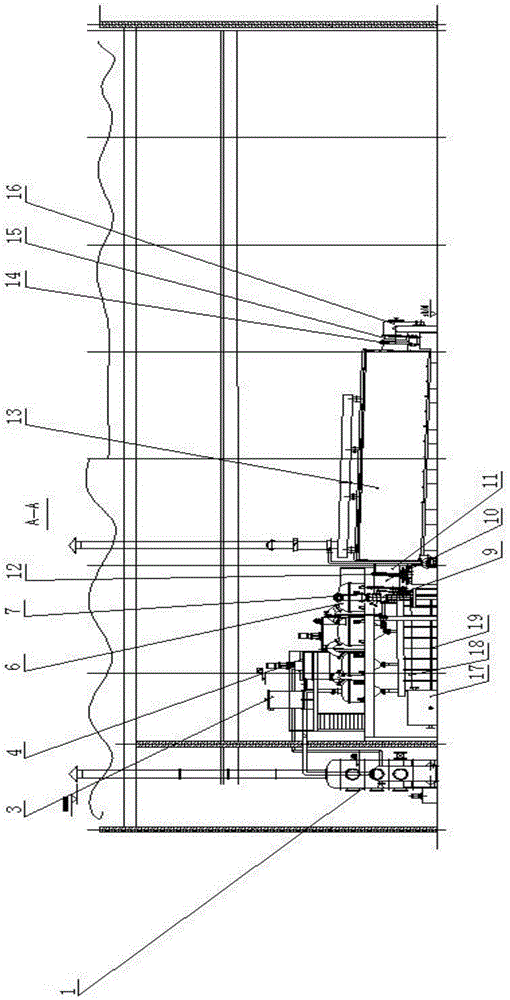

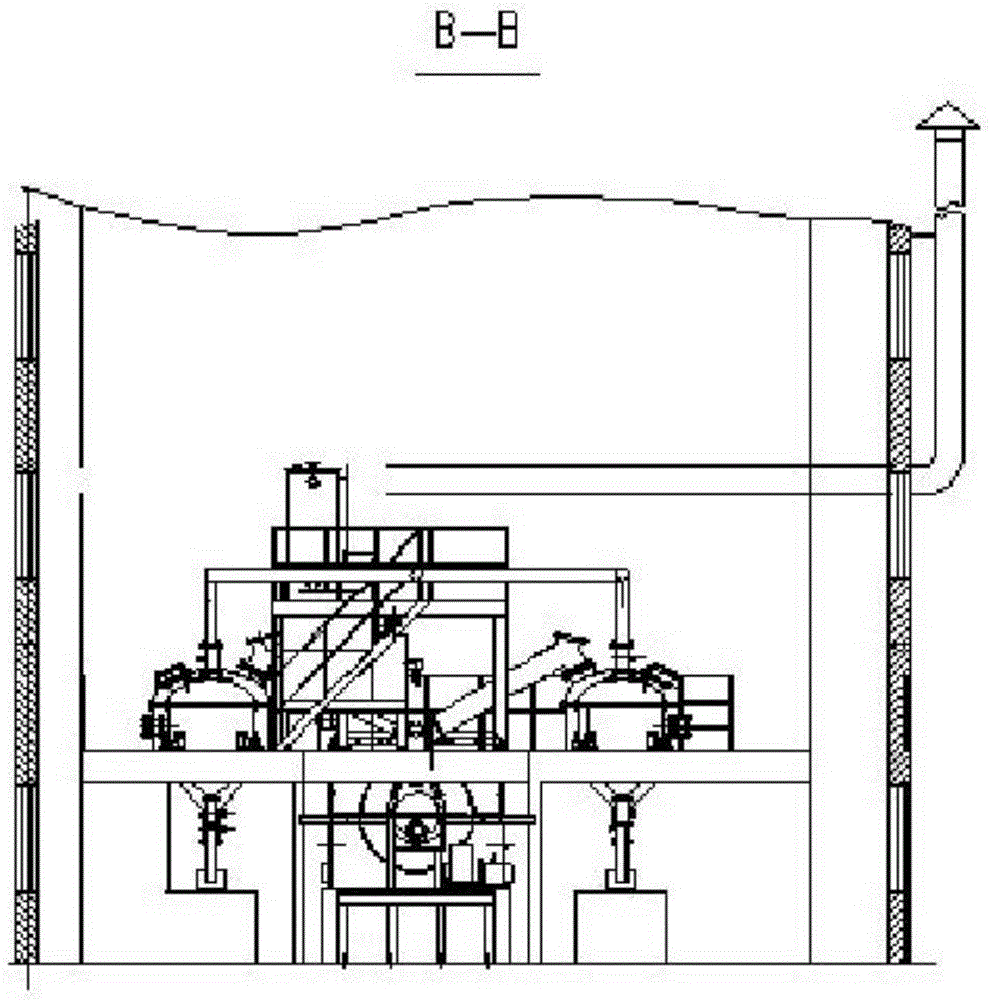

[0020] Such as figure 1 Shown is the structural representation of the top view of the present invention, figure 2 It is a structural schematic diagram of the A-A direction of the top view of the present invention, image 3 It is a structural schematic diagram of the B-B direction of the top view of the present invention, that is, the direction of the working principle of the present invention is from left to right, and the main steel platform 20 is provided with a pulping feeding system, a sulfated roasting rotary kiln, a selenium absorption system, and a production line control system .

[0021] The slurry feeding system includes a primary feeding slurry mixing tank 4, a secondary slurry mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com