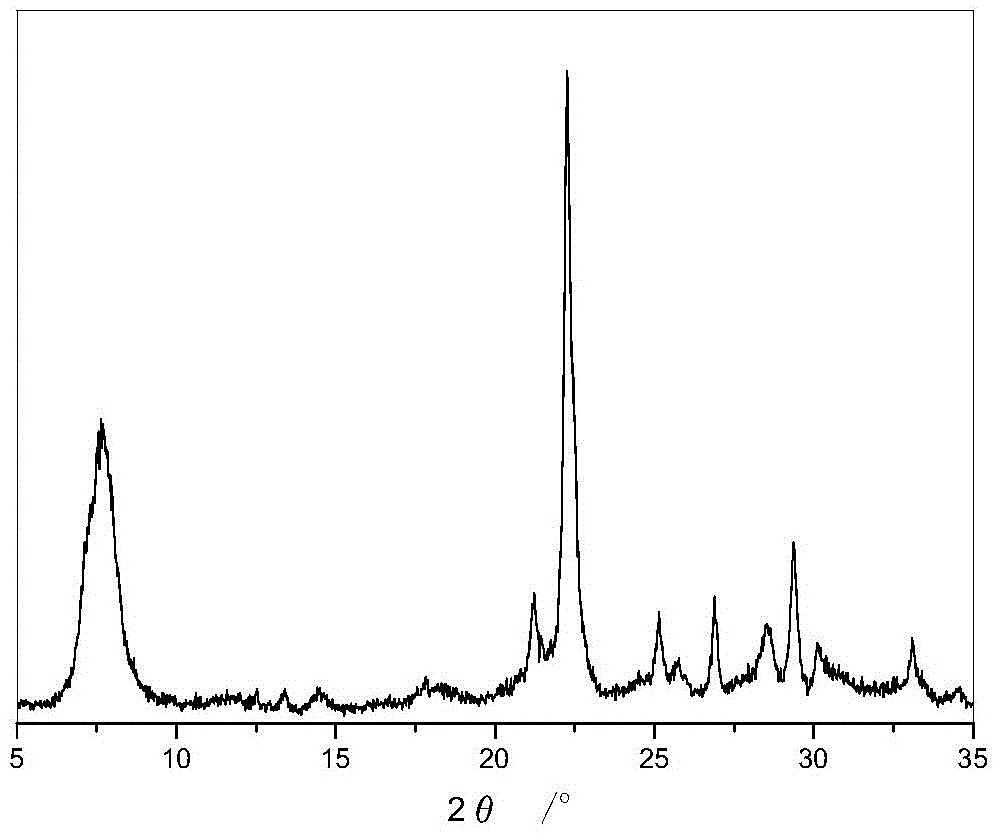

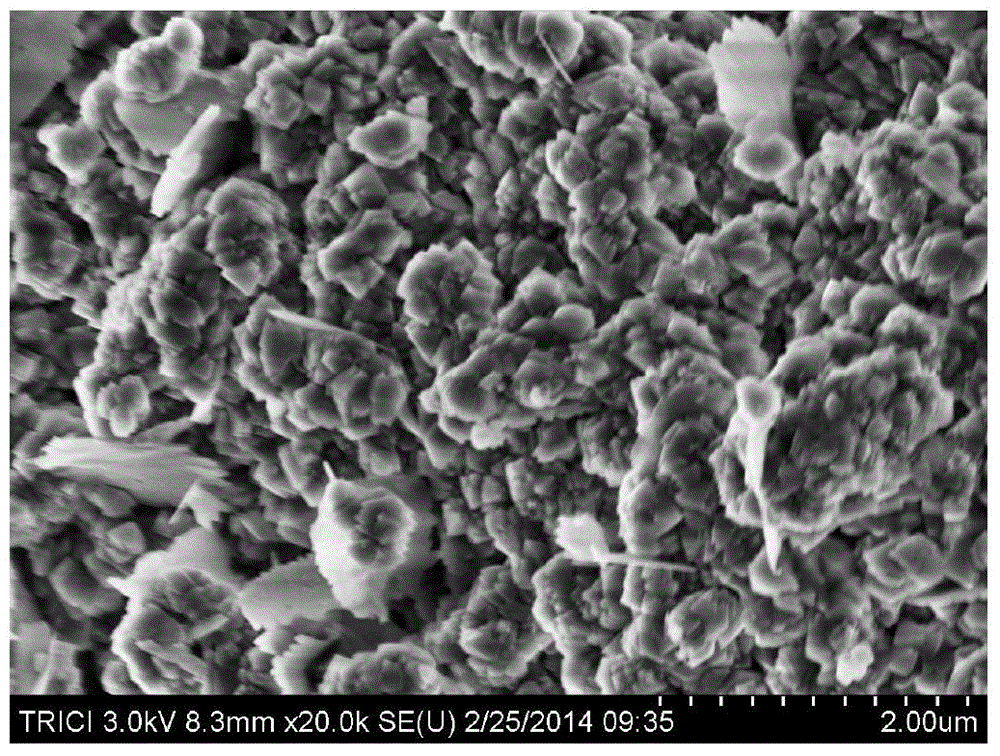

Beta zeolite molecular sieve and amine-free synthetic method thereof

A technology of beta zeolite and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of difficulty in obtaining high crystallinity products, unfavorable industrial scale production, and low yield of solid products, so as to shorten the crystallization time, It is beneficial to industrial production and shortens the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of amine-free synthetic method of Beta zeolite molecular sieve, comprises the following steps:

[0028] At 25°C, take 70.4ml of 3.98mol / l NaOH solution, add 1.8g of aluminum foil until it is completely dissolved while stirring, then add 60.1g of white carbon black and 90ml of deionized water, stir quickly and evenly, after stirring for 40min, add 0.6g of seed crystal , and then add 200ml of deionized water, and then stir for 1h to get a gel evenly. Move the gel into a stainless steel reaction kettle for crystallization at 130°C for 19 hours, then collect, wash, and dry to obtain the product.

Embodiment 2

[0030] A kind of amine-free synthetic method of Beta zeolite molecular sieve, comprises the following steps:

[0031] At 25°C, take 63.7ml of 3.98mol / l NaOH solution, add 5.5g of sodium metaaluminate until it dissolves completely, then add 60.1g of white carbon black and 100ml of deionized water, stir quickly and evenly, after stirring for 50min, add 3g Seed crystals, add 200ml of deionized water, and then stir for 1.5h until uniform to obtain a gel. Move the gel into a stainless steel reaction kettle for crystallization at 135°C for 20 hours, then collect, wash, and dry to obtain the product.

Embodiment 3

[0033] A kind of amine-free synthetic method of Beta zeolite molecular sieve, comprises the following steps:

[0034] At 25°C, take 90.5ml of 3.98mol / l NaOH solution, add 14.6g of aluminum isopropoxide until completely dissolved while stirring, then add 60.1g of white carbon black and 100ml of deionized water, stir quickly and evenly, stir for 1 hour and then add Add 4.8g of seed crystals, add 210ml of deionized water, and stir for 1.5h to obtain a gel. Move the gel into a stainless steel reaction kettle for crystallization at 136°C for 21 hours, then collect, wash, and dry to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com