A functional porous cement-based composite material and its preparation method

A composite material and cement-based technology, applied in the field of material science and engineering, can solve the problems of difficult large-scale application and high cost of ceramic membranes, and achieve the effects of easy acquisition, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

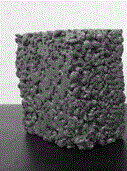

Image

Examples

Embodiment 1

[0036] The preparation method of functional porous cement-based composite material is as follows:

[0037] 1) Preparation of graphite oxide: Weigh 5g of graphite and 5g of sodium nitrate and place them in a three-necked flask containing 160mL of 98wt% concentrated sulfuric acid, stir and react at constant temperature in an ice bath for 1h, then continue to gradually add 23g of potassium permanganate (note that Keep the temperature), and continue to stir for 2 hours, then place at room temperature for a week, then dilute with 500 mL of 5% sulfuric acid solution (note that the temperature will rise rapidly), stir for 2 hours, and finally add 15 mL of 30% hydrogen peroxide to reduce the remaining potassium permanganate for 2 hours. After repeated washing and centrifugation, the graphite oxide is obtained by vacuum drying until it is neutral.

[0038] 2) Preparation of titanium dioxide colloidal suspension solution: firstly, 100 mL of tetrabutyl titanate and 25 mL of acetylacetone...

Embodiment 2

[0043] Preparation of undoped porous cementitious composites:

[0044] 1) Preparation of cement composite slurry: Weigh 350g of water, 700g of cement, and 600g of ceramsite (particle size after pulverization: 0.5-5mm), mix them, and add them to a mixer to stir for 3 minutes to obtain a cement composite slurry.

[0045] 2) Forming and maintenance of porous cement-based composite materials: After injecting the cement composite slurry in the above 1) into the mold (150 × 150 × 150 mm), flattening and vibrating, in order to facilitate the algae separation test, especially in the center of the upper surface. Press out a small pit with a depth of about 2cm, and release it after 24 hours. The demolded samples were placed in the laboratory for 28 days under natural conditions to obtain undoped porous cement-based composites.

Embodiment 3

[0047] The preparation method of functional porous cement-based composite material is as follows:

[0048] 1) Preparation of graphite oxide solution: Weigh 5g of graphite flakes and 5g of sodium nitrate and place them in a three-necked flask containing 160mL of 98% concentrated sulfuric acid, stir and react at constant temperature in an ice bath for 1h, then continue to gradually add 23g of potassium permanganate slowly , and kept stirring at room temperature for 2 hours, then placed at room temperature for a week, then diluted with 500 mL of 5% sulfuric acid solution, stirred for 2 hours, and finally added 15 mL of 30% hydrogen peroxide to reduce the remaining potassium permanganate for 2 hours. After repeated washing and centrifugation, the graphite oxide is obtained by vacuum drying until it is neutral.

[0049] 2) Preparation of titanium dioxide colloidal suspension solution: firstly, 20 mL of tetrabutyl titanate and 5 mL of acetylacetone were dissolved in 40 mL of absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com